Side-inserted mounting and fixing mechanism for intercooler

A technology for fixing mechanisms and coolers, applied in the direction of machines/engines, charging systems, mechanical equipment, etc., can solve problems such as inconvenient installation and disassembly, high risk, engine damage and scrapping, etc., to ensure installation operability and fixing methods Safe and reliable, the effect of reducing dimensional tolerance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

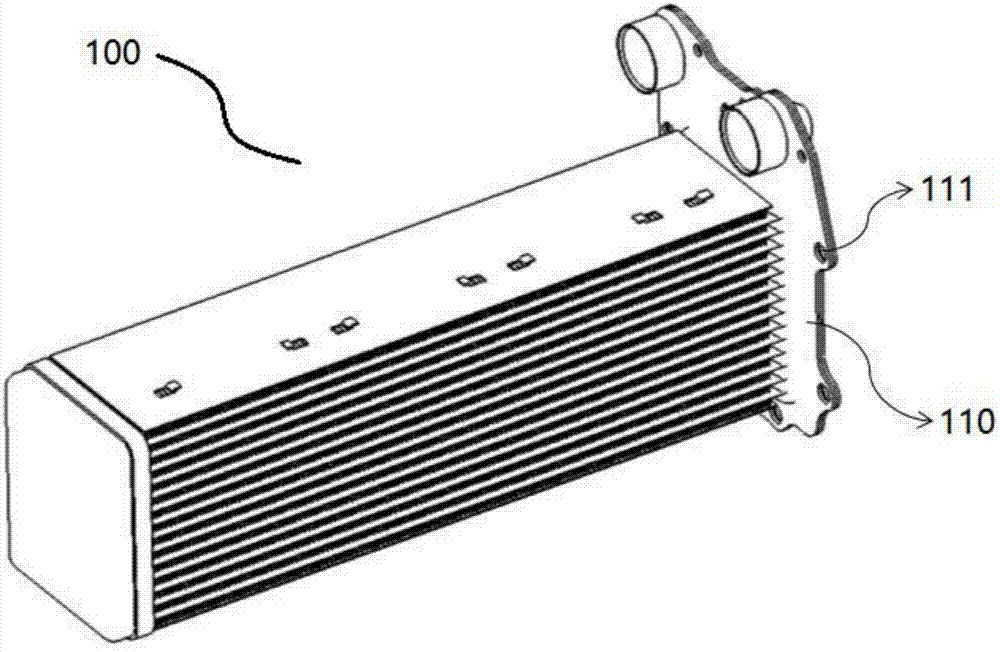

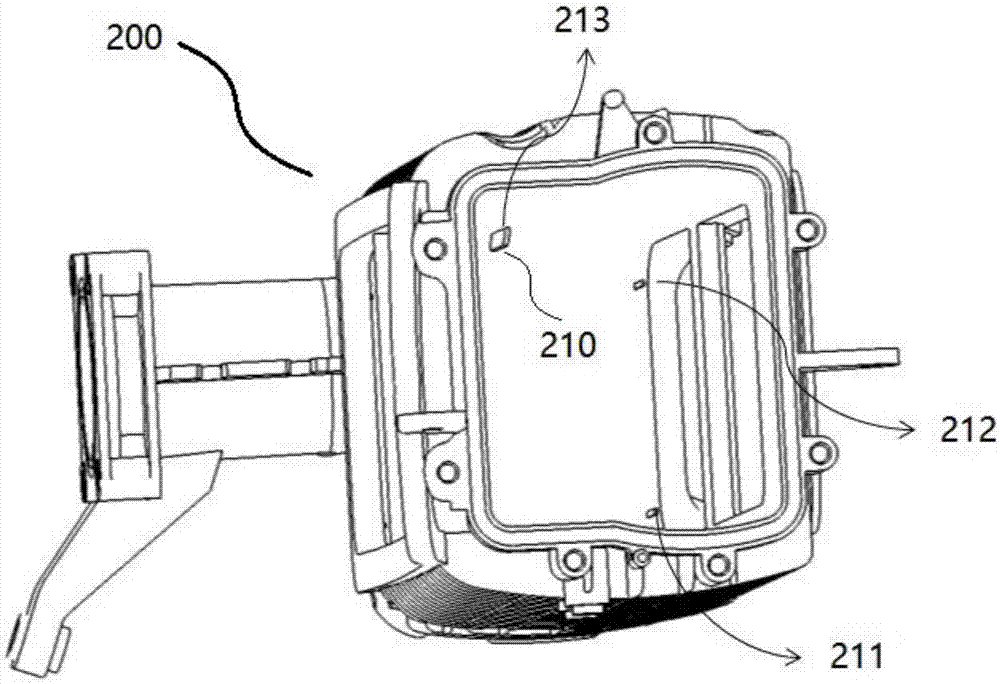

[0031] Example 1 as Figure 4-5 As shown, this embodiment provides a side-inserted intercooler installation and fixing mechanism, including an intake manifold 200 and an intercooler 100 installed in the intake manifold 200, and the other end of the intercooler 100 passes through The tapping screw is fastened on the flange surface, and the other end is fixed in the intake manifold 200. The installation and fixing mechanism also includes: at least one protrusion 120 arranged on the top of the intercooler 100; There is at least one fixing hole 220, and the fixing hole 220 is connected with the protrusions 120 one by one. Specifically, the protrusion 120 can be embedded in the fixing hole 220 and arranged in an interference fit with the fixing hole 220. The protrusion 120 is fixed on the top end surface of the protrusion 120, and it is made of hard or soft material. The shape of the protrusion 120 is the same as that of the fixing hole 220, so as to ensure that the protrusion 120...

Embodiment 2

[0034] Example 2 as Figure 4-5As shown, this embodiment provides an installation and fixing mechanism for a side-inserted intercooler, including an intake manifold 200 and an intercooler 100 installed in the intake manifold 200, and also includes: At least one protrusion 120 on the top of 100; at least one fixing hole 220 arranged in the intake manifold 200, the fixing hole 220 is connected to the protrusion 120 one by one; and also includes a shock absorber sleeved on the protrusion 120 The block 130 , the protrusion 120 is embedded in the fixing hole 220 through the shock absorbing block 130 .

[0035] As a preferred technical solution of this embodiment, the shock absorbing block 130 is made of rubber material or functional soft material, and the functional soft material is TPU, TPE, TPR or silicone material, and the shock absorbing block 130 with good wear resistance and elasticity can Effectively guarantee the stability of the connection between the fixing hole 220 and ...

Embodiment 3

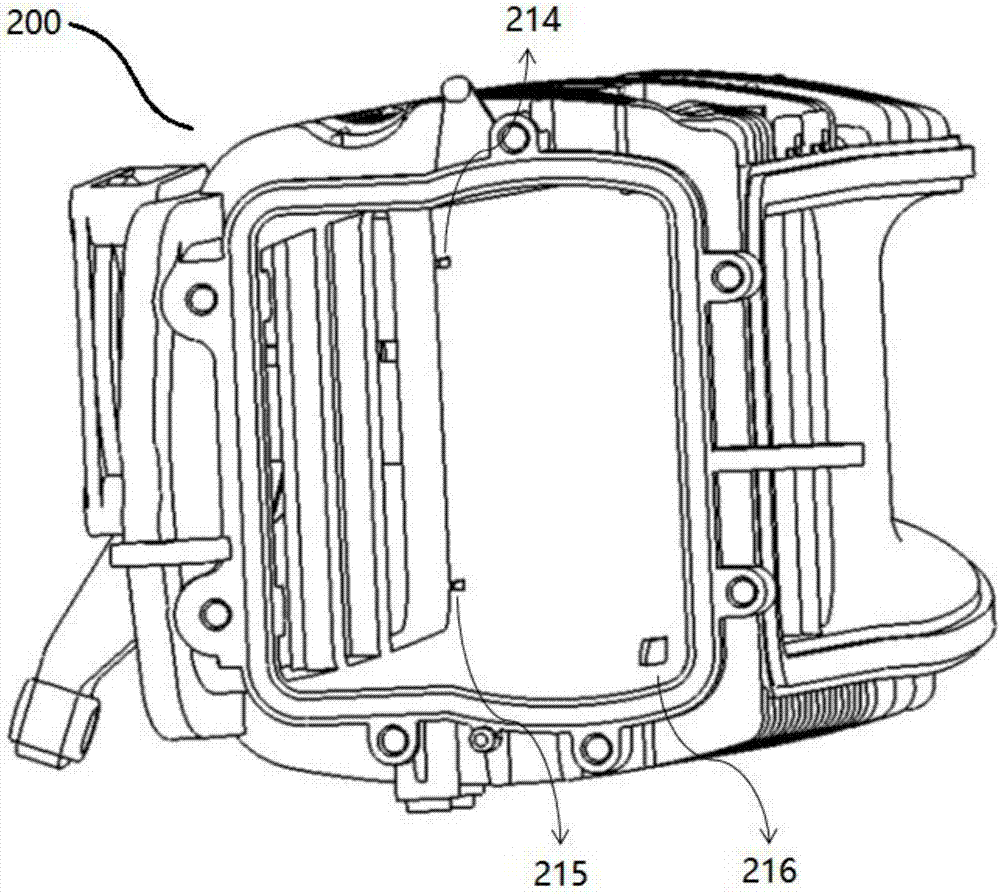

[0038] Example 3 as Figure 6-13 As shown, this embodiment provides an installation and fixing mechanism for a side-inserted intercooler, including an intake manifold 200 and an intercooler 100 installed in the intake manifold 200, and also includes: At least one protrusion 120 on the top of 100; at least one circular fixing hole 221 arranged in the intake manifold 200, the circular fixing hole 221 is connected with the protrusions 120 one by one; The circular shock absorbing block 131 on the top, the protrusion 120 is embedded in the square fixing hole 221 through the circular shock absorbing block 131, wherein the circular shock absorbing block 131 and the circular fixing hole 221 both adopt a circular structure. Interact with nested connections.

[0039] Specifically, the installation and fixing method between the intercooler 100 and the intake manifold 200 is designed in advance, and the numbers and positions of the protrusions 120 , the circular damping blocks 131 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com