Anti-aging composition and preparation method thereof

A composition and anti-aging technology, applied in the directions of pharmaceutical formulations, cosmetic preparations, cosmetic preparations, etc., can solve the problems of consumer safety risks, environmental protection risks, pollution, safety risks caused by adding antiseptics, etc. Function repair, easy to disperse, skin protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

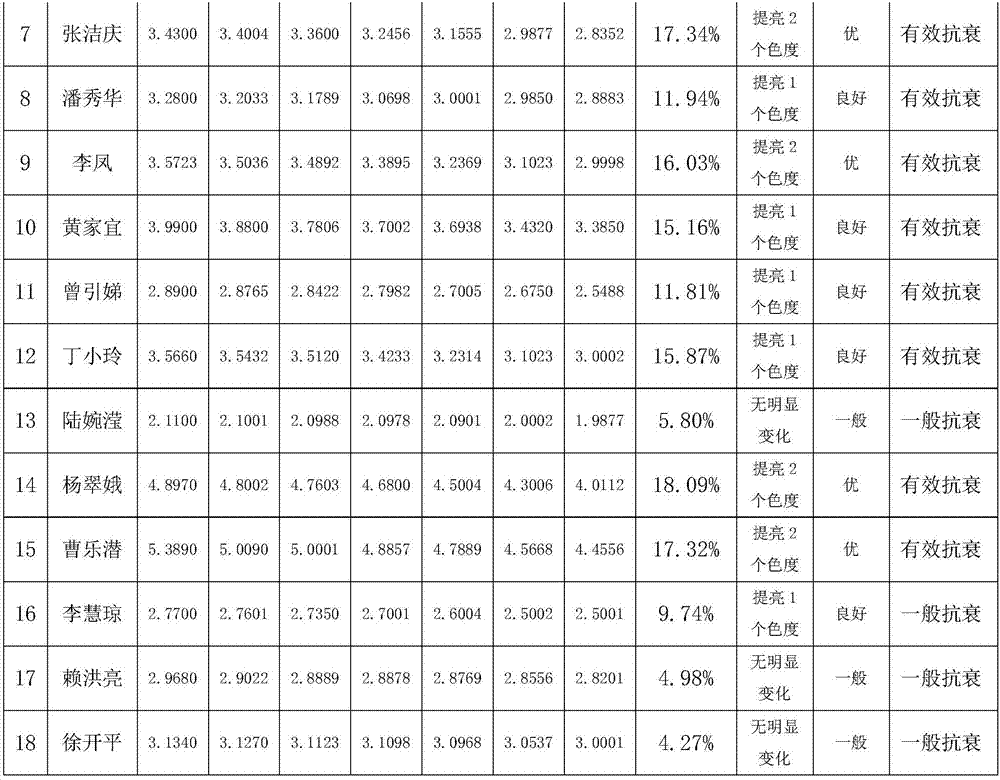

Examples

Embodiment 1

[0019] Embodiment 1: An anti-aging composition, which is composed of the following components in weight percentage: vitamin A 0.7%, vitamin E 17%, sucrose stearate 1.1%, calamine 11%, and the balance is betaine. Mix vitamin A and vitamin E and stir evenly to form phase A; soak the calamine in pure water, then grind it with a three-wheel roller machine to ensure that the particle size is below 1 micron, and then dry it for later use to form phase B; Phase A is evenly sprayed on phase B, and stirred evenly to form phase C; betaine, sucrose stearate, and phase C are uniformly mixed.

Embodiment 2

[0020] Embodiment 2: An anti-aging composition is composed of the following components in weight percentage: 1.1% vitamin A, 23% vitamin E, 5.9% sucrose stearate, 23% calamine, and the balance is betaine. Mix vitamin A and vitamin E and stir evenly to form phase A; soak the calamine in pure water, then grind it with a three-wheel roller machine to ensure that the particle size is below 1 micron, and then dry it for later use to form phase B; Phase A is evenly sprayed on phase B, and stirred evenly to form phase C; betaine, sucrose stearate, and phase C are uniformly mixed.

Embodiment 3

[0021] Embodiment 3: An anti-aging composition, which is composed of the following components by weight percentage: vitamin A 1.0%, vitamin E 20%, sucrose stearate 3%, calamine 16%, and the balance is betaine. Mix vitamin A and vitamin E and stir evenly to form phase A; soak the calamine in pure water, then grind it with a three-wheel roller machine to ensure that the particle size is below 1 micron, and then dry it for later use to form phase B; Phase A is evenly sprayed on phase B, and stirred evenly to form phase C; betaine, sucrose stearate, and phase C are uniformly mixed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com