Elevator counterweight

A counterweight and component technology, applied in the field of assembly and counterweight, can solve problems such as difficulties and expensive modules, and achieve the effect of increasing volumetric efficiency, reducing height, and unaffected structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

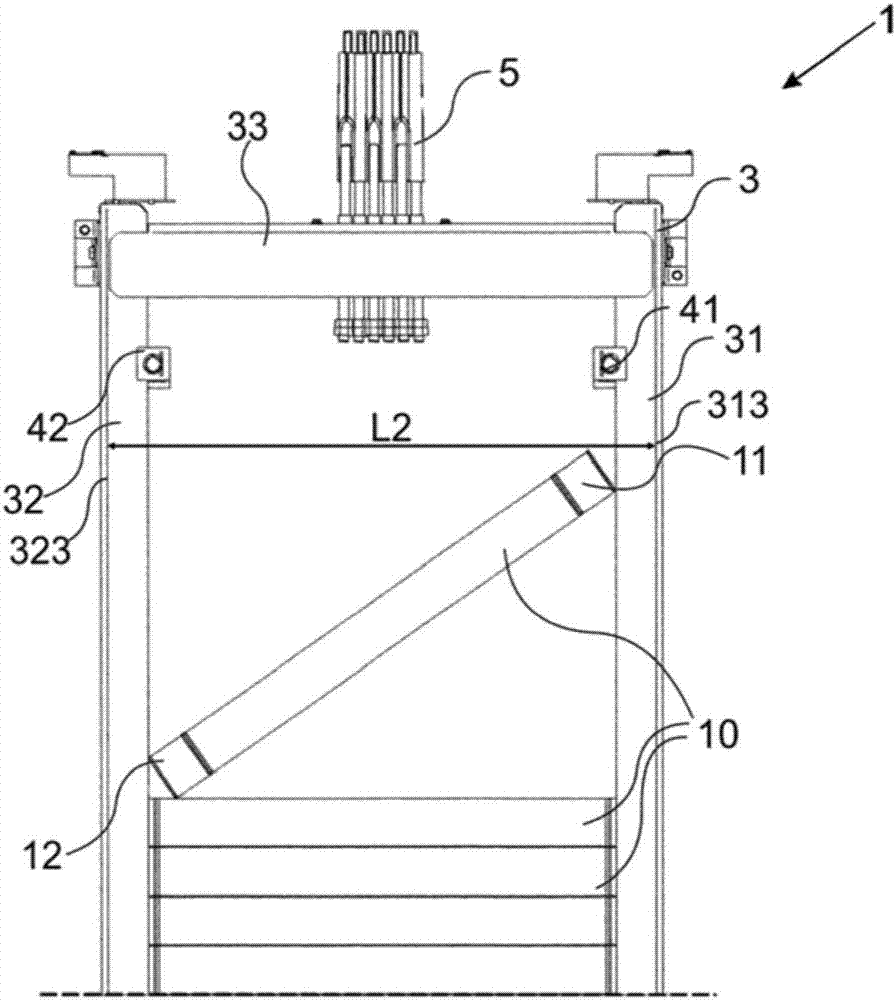

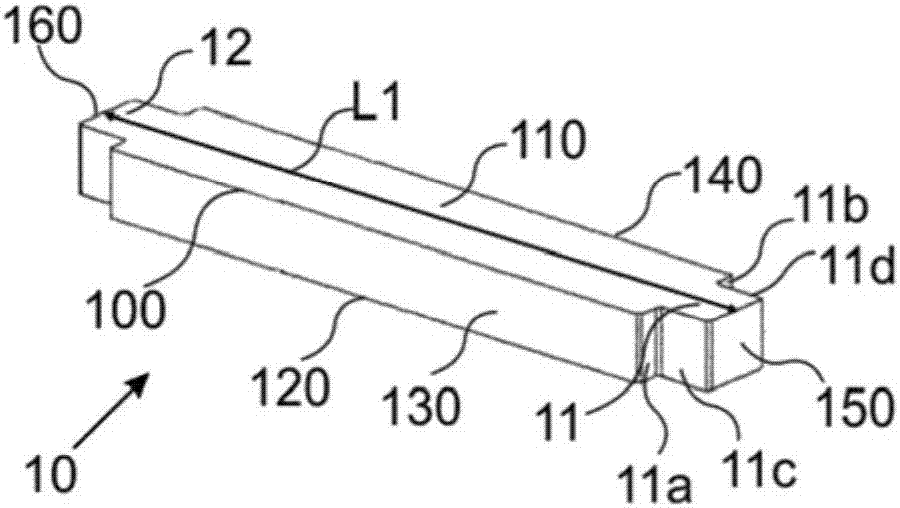

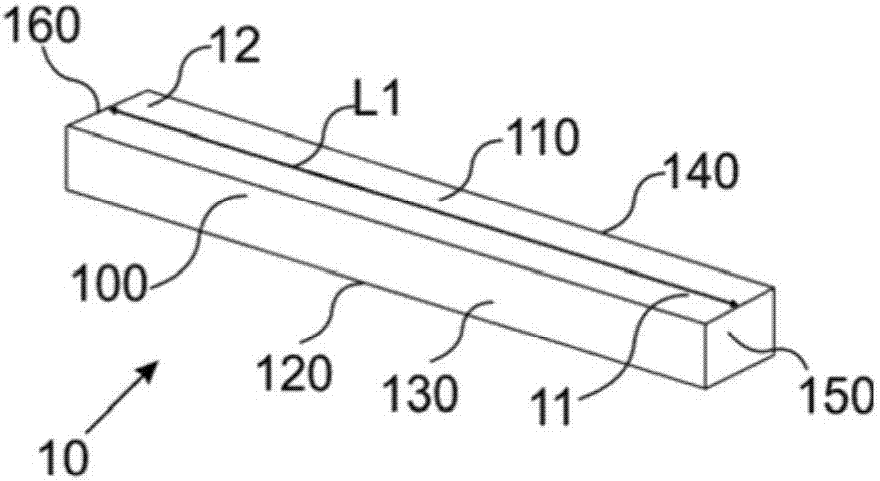

[0053] exist Figure 1a , Figure 2a , Figure 3a , Figure 4a and Figure 5a A counterweight 1 according to the invention is shown in . The counterweight comprises a frame 3 comprising a vertical first side beam 31 , a vertical second side beam 32 and two horizontal beams, of which only the upper top beam 33 is shown in all figures. It will be understood that the bottom beam is arranged between the two side beams 31 , 32 at the bottom of the frame 3 , extends horizontally between them and is aligned with the top beam 33 .

[0054] The frame 3 is filled with balancing modules 10 , 20 from the bottom beam upwards. Initially, the first modules 10 are used such that the first of the first modules 10 is positioned directly on top of the bottom beam, although the bottommost part of the bottom beam and counterweight 1 is not shown in the figure.

[0055] The counterweight 1 also comprises means 5 for attaching hoisting cables to the frame 3, and locking means 41, 42 for securin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com