Feeding mechanism for assembling puncture type bare needle protection covers

A technology of feeding mechanism and protective cover, which is applied in the direction of conveyor objects, transportation and packaging, conveyor control devices, etc., can solve the problem that the falling position of the needle seat needle tube assembly and the protective cover cannot be aligned, the jig cannot move forward or There are deviations in the moving distance, and the protection cover cannot be reduced, so as to avoid movement, reduce defective products, and reduce cleaning work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

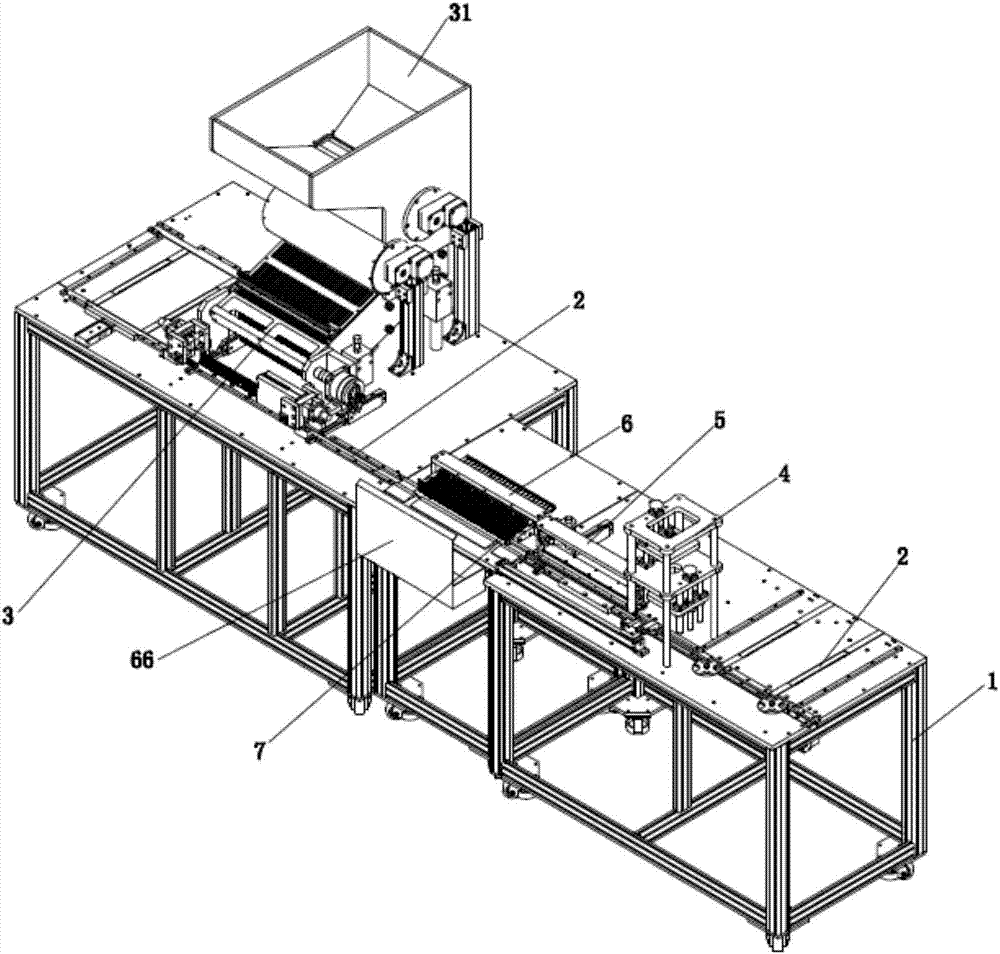

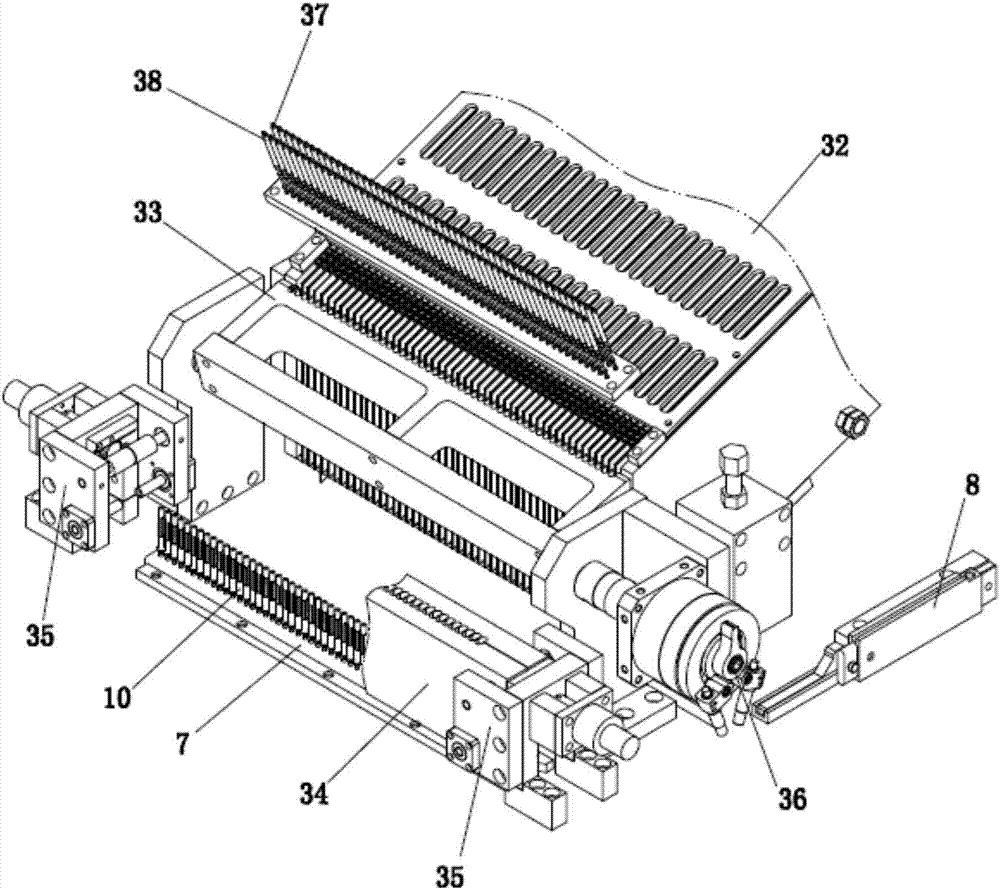

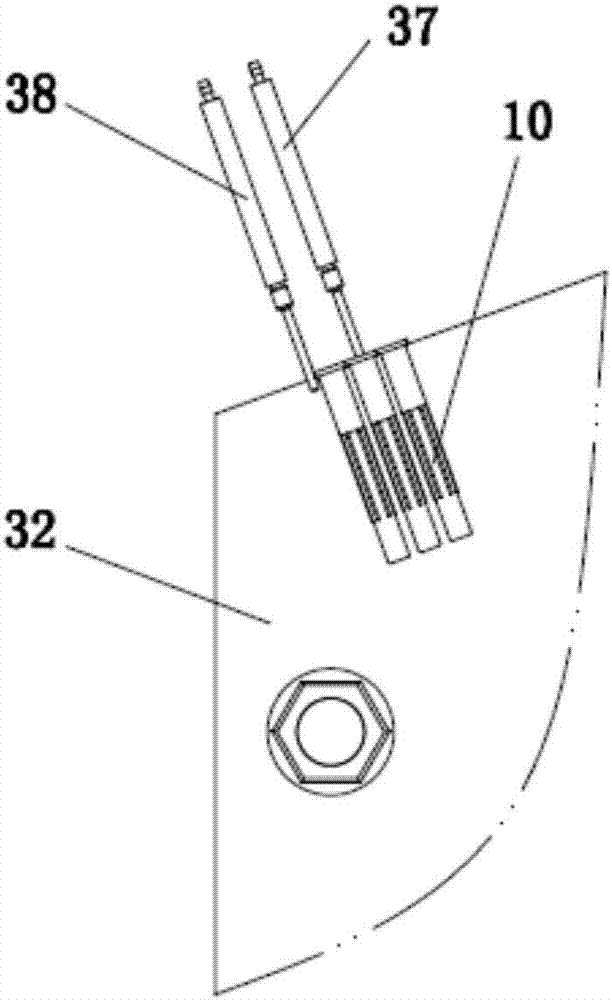

[0037] The specific embodiments of the present invention are as Figure 1 to Figure 8 As shown, a feeding mechanism for assembling a puncture-type bare needle protective cover includes a workbench 1, on which is provided a transmission mechanism 2 for moving a jig 7 carrying a needle holder needle tube assembly 9, and It includes an image comparison device 4, an air blocking detection device 5, a defective product discharge device 6 and a protective cover fastening device 3 arranged in sequence along the conveying direction of the transmission mechanism 2. The protective cover fastening device 3 can only buckle the protective cover The structure that fits the remaining needle holder needle tube assembly 9 on the jig 7. In this embodiment, the transmission mechanism 2 is a conveyor belt, and the jig 7 is provided with 50 vertical positioning posts.

[0038] After the needle holder and needle tube assembly 9 on the jig 7 are glued to each other and enter the adhesive curing oven, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com