Thermal energy machine with flow guide devices in the diffusor

A technology of diffuser and thermal energy, which is applied to components of pumping devices for elastic fluids, gas turbine devices, machines/engines, etc., and can solve problems such as low efficiency of turbines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

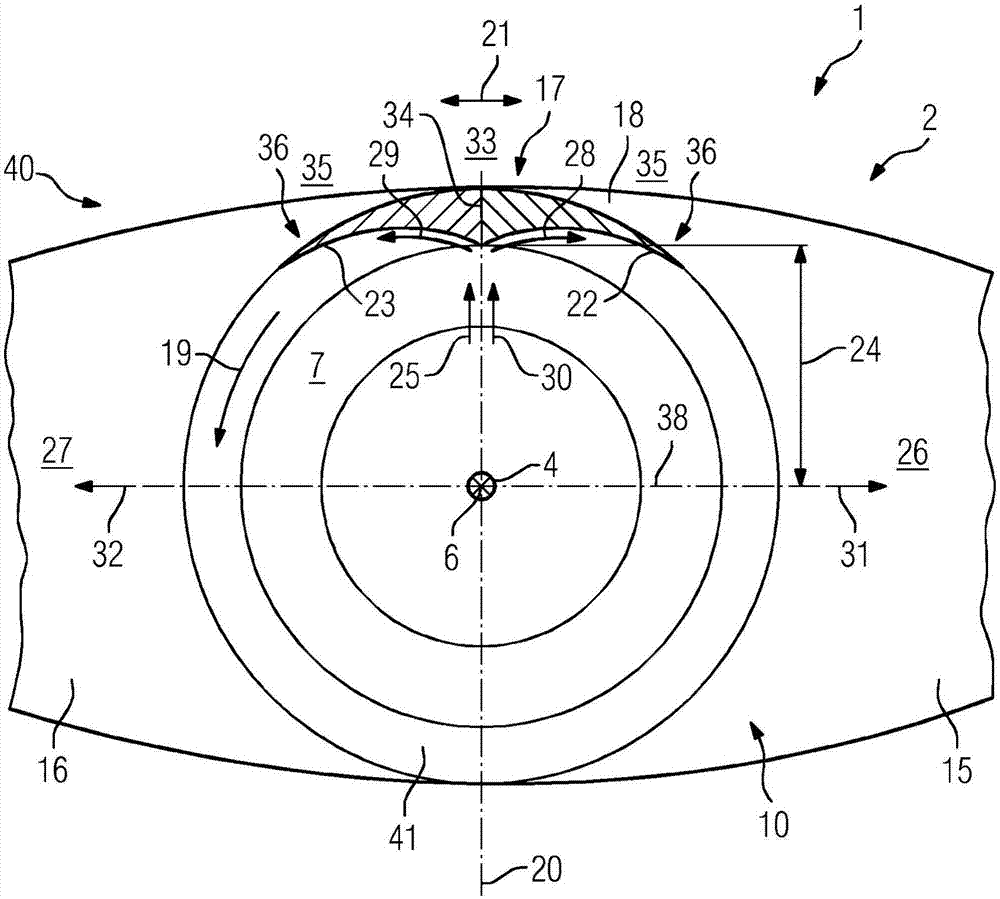

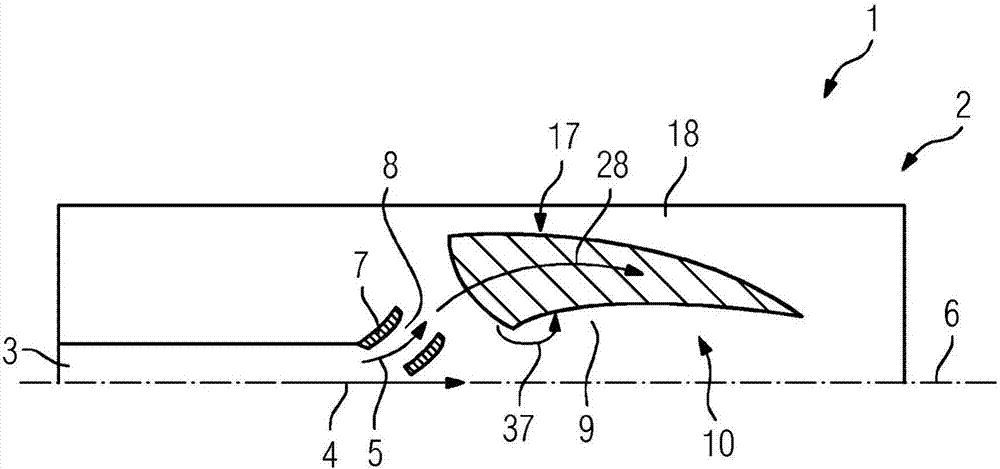

[0037]figure 1 with figure 2 The turbomachine 1 shown at least in part is a gas turbine 2 .

[0038] Here, the turbine 1 essentially comprises a compressor 3 for compressing an air mass flow 5 flowing in an axial flow direction 4 (see figure 2 ) (marked with numbers for exemplary purposes only).

[0039] Here, the compressor 3 is arranged concentrically around a longitudinal center axis 6 of the turbine, which likewise represents the machine axis.

[0040] Downstream of the compressor 3 , ie arranged downstream of the compressor 3 in the flow direction 4 , a diffuser 7 is arranged axially upstream and downstream, wherein the diffuser 7 has a diffuser that is formed concentrically around the longitudinal center axis 6 of the turbine. The diffuser outlet 8 from which the air mass flow 5 exits is correspondingly decelerated into the diffuser outlet region 9 .

[0041] The diffuser outlet area 9 is delimited in particular by the inner casing 10 of the turbine 1 and ultimately...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com