Coke dry quenching (CDQ) furnace inner lining refractory dismantling and discharging method

A technology for refractory materials and dry quenching furnaces, which is used in furnaces, lining repairs, furnace components, etc., can solve the problems of high construction cost, high labor intensity, and many measures and materials, so as to achieve simple and applicable operation, reduce labor intensity, and reduce The effect of construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

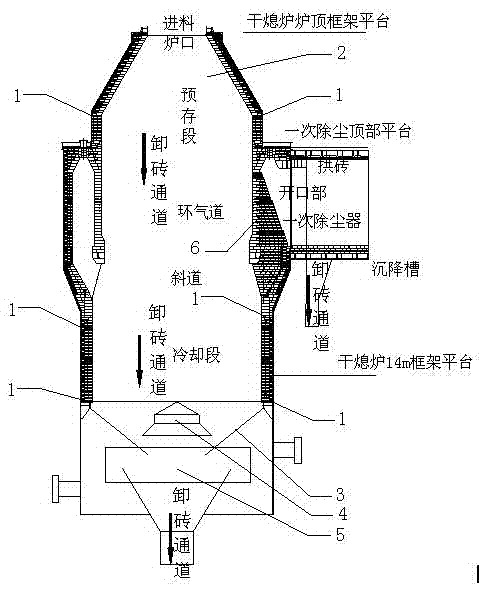

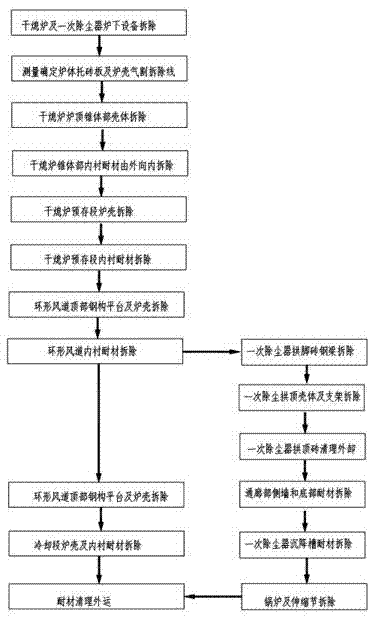

[0040] see now figure 1 and figure 2 , figure 1 It is a schematic diagram of removing refractory bricks from CDQ furnaces according to the embodiment of the present invention, figure 2 It is a flow chart of the construction process for removing the refractory lining of the CDQ furnace according to the embodiment of the present invention.

[0041] The refractory material removal and unloading method for CDQ furnace lining of the present invention comprises the following steps:

[0042] a. Remove the equipment under the furnace

[0043] Empty the residual coke in the CDQ furnace tank, remove the vibrating feeder, rotary sealing valve, furnace plate gate, adjustment rod, etc. under the CDQ furnace body, and seal the basement hole with a 20mm thick steel plate; material channel and temporary storage yard.

[0044] b. Determine the gas secant line of the furnace shell

[0045]According to the refractory masonry drawing of the CDQ furnace and the permanent elevation referenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com