Righting structure for preventing sucker rod pump plunger from eccentrically-wearing

An oil well pump and plunger technology is applied in the field of righting structures for preventing eccentric wear of the plunger of a rod oil well pump.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

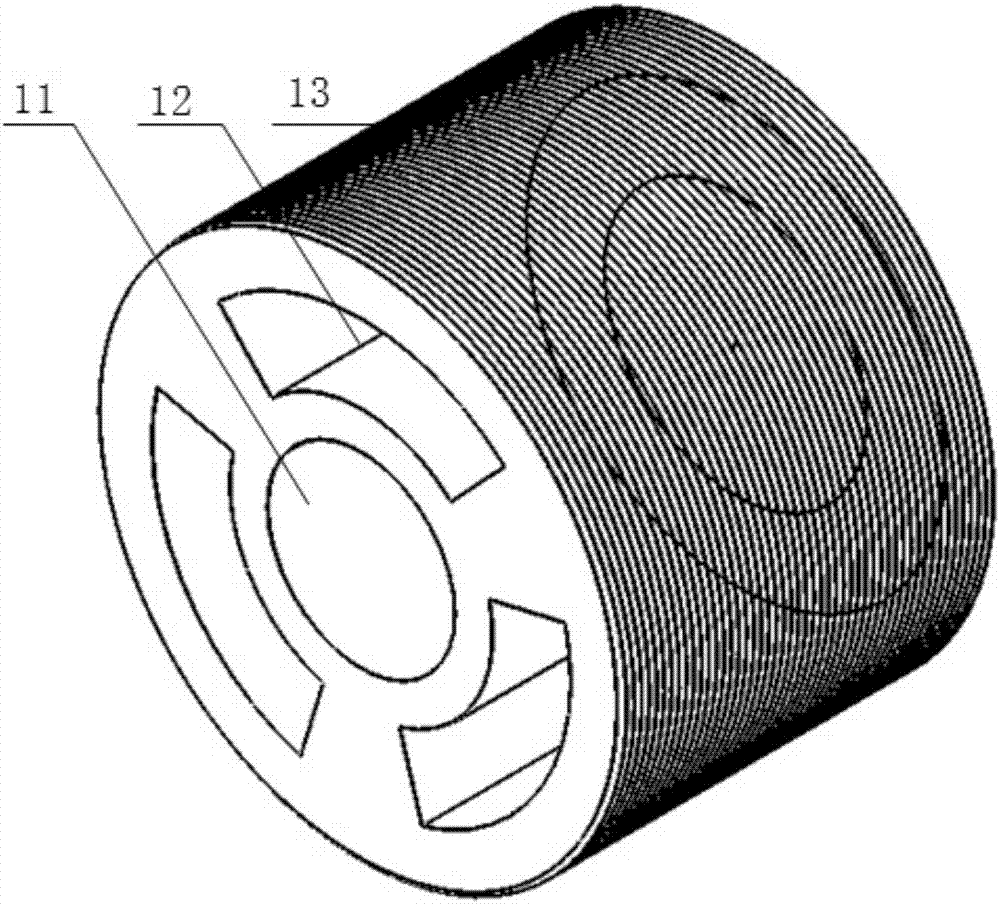

[0026] Such as figure 1 , 3 As shown, the centralizing structure for preventing the eccentric wear of the plunger of the rod well pump disclosed by the present invention includes a centralizing device 1, an equal-diameter sucker rod 2, a pump barrel 3 and a plunger 4, and the centralizing device 1 and the plunger 4 are coaxially arranged In the pump cylinder 3, the centralizing device 1 is located at the outer end of the plunger 4. The outer wall of the centralizing device 1 is threadedly matched with the inner wall of the pump cylinder 3. The center of the centralizing device 1 has an oil rod guide hole 11 arranged axially. The inner diameter of the oil rod guide hole 11 is Adapted to the outer diameter of the equal-diameter sucker rod 2, one end of the equal-di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com