Tool for realizing rapid adjustment for fixture

A rapid adjustment and tool technology, applied in the automotive field, can solve the problems of inconvenient use, complex structure, difficult processing and manufacturing, and achieve the effect of stably transmitting torque and increasing torque.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings.

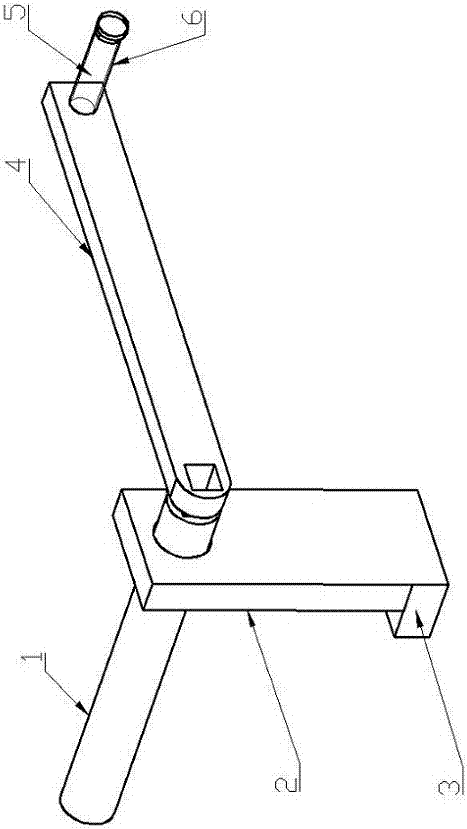

[0029] Such as figure 1 As shown, a tool for quickly adjusting tooling includes a transfer rod 1 , a bracket 2 , a bracket pad 3 , a rocker arm 4 , and a crank handle 5 .

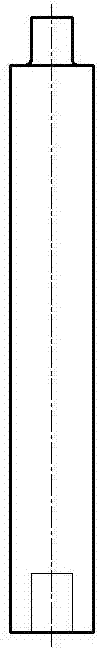

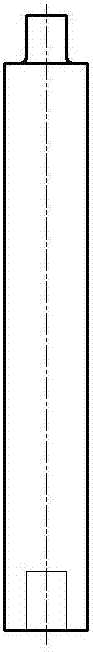

[0030] A support pad 3 is provided at the bottom of the support 2 , a circular hole is provided at the top of the support 2 , and the transmission rod 1 passes through the circular hole on the support 2 .

[0031] One end of the crank handle 4 is processed with a square hole, and the other end of the rocker arm 4 is processed with a mounting hole. The transmission rod 1 journal extending out of the support 2 is arranged in the square hole at the end of the rocker arm 4. The installation of the end of the rocker arm 4 Rocking handle 5 is set in the hole.

[0032] The rocker arm 4 is arranged parallel to the support 2 . The transmission rod 1 is arranged parallel to the crank handle 5 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com