One-way hydraulic diameter-expanding pipeline breakage simulation experiment device and method

A technology for simulating experimental devices and pipelines, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problems of difficult preparation of pipeline fracture test specimens, high risk, large errors, etc., to reduce work risks and facilitate Obtaining and reducing the effect of size error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

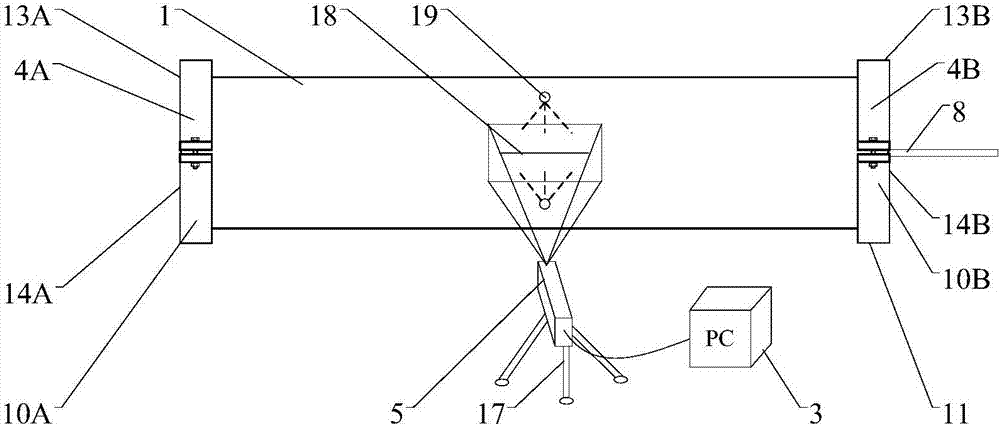

[0018] Such as Figure 1 to Figure 5 As shown, the unidirectional hydraulic expansion pipe fracture simulation experiment device includes: pipe support system 11, pipe expansion support system 12, oil inlet pipe 8, and DIC test system 17; the pipe support system 11 supports both ends of the experimental pipe section 1 ; The side wall of the experimental pipe section 1 is provided with an axially penetrating prefabricated crack 18, and the prefabricated crack 18 is symmetrical about the axial midplane of the experimental pipe section 1; the inner end surface of the pipe expansion system 12 coincides with the axial midplane of the experimental pipe section 1 The oil inlet pipe 8 provides hydraulic power for the pipeline expansion system 12; the DIC test system 17 performs real-time observation of the fracture process of the experimental pipe section 1.

[0019] The pipe support system 11 includes: upper left collar 13A, lower left collar 14A, upper right collar 13B, lower right ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com