An air blower

A blower and air supply technology, which can be applied to mechanical equipment, machines/engines, liquid fuel engines, etc., and can solve problems such as inconvenience in use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

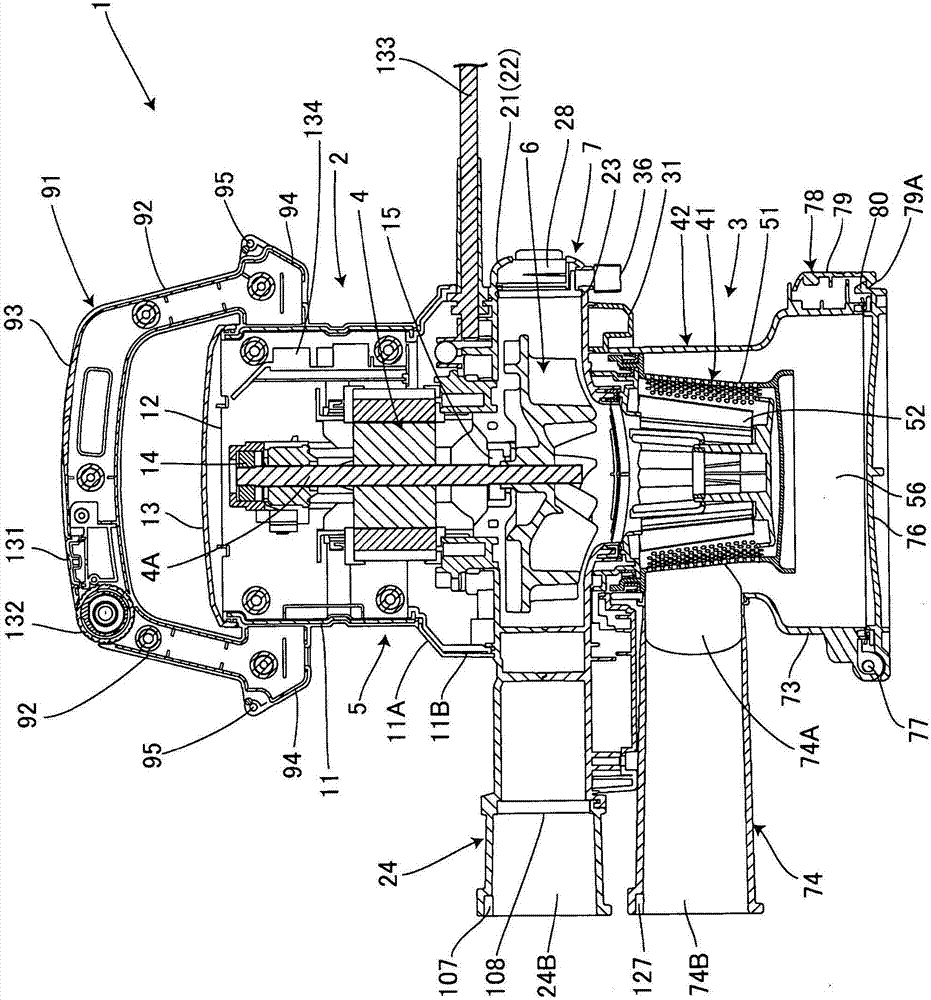

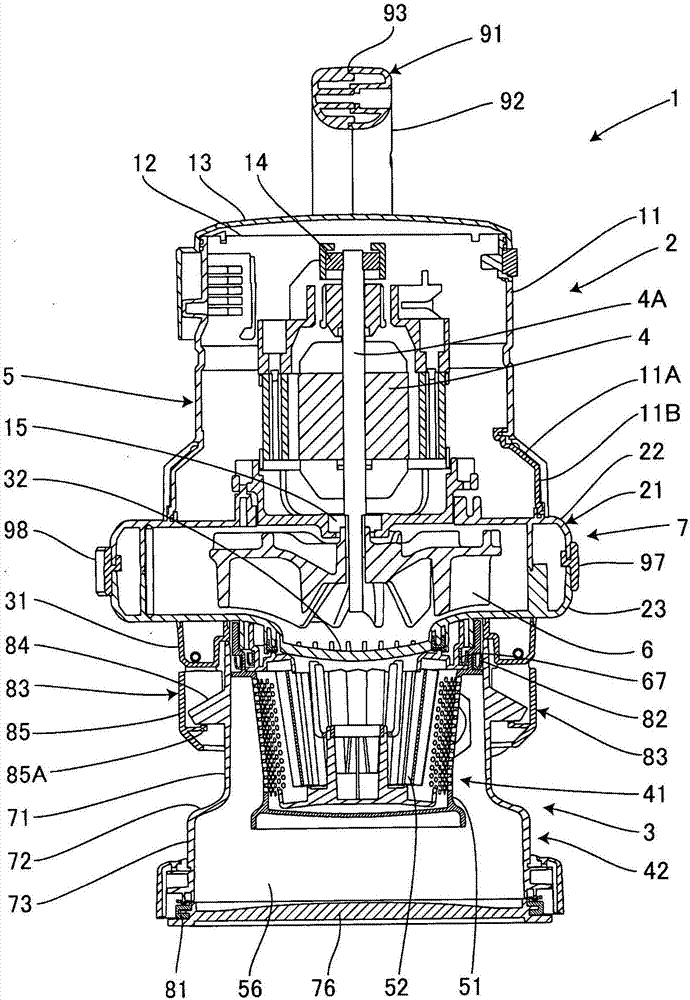

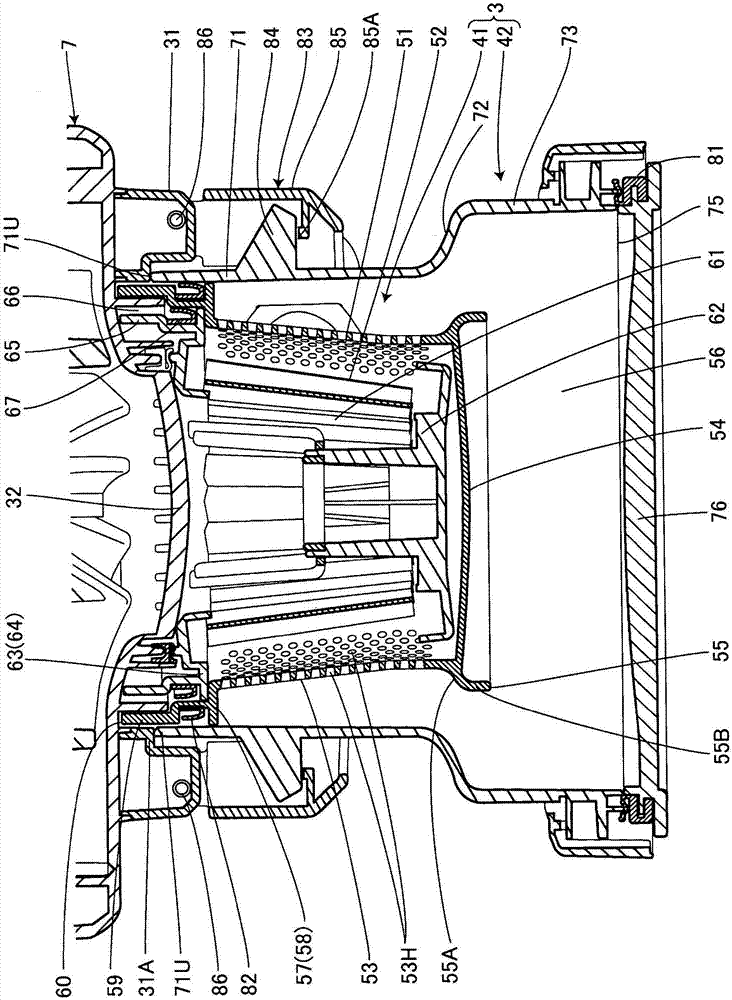

[0063] Below, based on Figure 1 to Figure 12 Example 1 of the present invention will be described. Reference numeral 1 is the blower of the present invention. This blower 1 has a main body 2 and a dust removal part 3 detachably attached to the lower part of this main body 2 . In addition, the main body 2 has a main body part 5 and a blower part 7, the main part 5 has a built-in motor 4, and the blower part 7 is arranged at the bottom of the main part 5 and has a centrifugal fan 6 built in. The dust removal unit 3 is detachably attached to the lower portion of the wind unit 7 .

[0064] A cylindrical main body case 11 is provided on the outside of the main body 5, and an enlarged portion 11A extending downward and conically expanding is provided on the lower side of the main body case 11. The enlarged portion 11A is The lower main body case lower portion 11B is formed to have a larger diameter than the upper portion. In addition, the upper opening 12 of the main body case ...

Embodiment 2

[0120] Figure 13 as well as Figure 14 Embodiment 2 of the present invention is shown, and the same parts as those in the above-mentioned Embodiment 1 are given the same reference numerals, and the explanation thereof will be omitted, and will be described in detail. Figure 13 as well as Figure 14 A modified example of the mounting positions of the discharge port 24 and the air intake port 74 is shown.

[0121] Such as Figure 13 as well as Figure 14As shown, in this example, the suction port 74 is protrudingly provided at the lower part of the air blower housing 21 of the main body 2 on the left side, and in addition, on the right side of the air blower housing 21 The discharge port 24 is provided, and the suction port 74 and the discharge port 24 are parallel to each other and face forward.

[0122] In addition, a dust box side connecting hole 136 is formed on the upper left side of the dust collecting box 42 , and an air inlet side connecting hole 137 connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com