Double coal seam four-channel packer layered pressure control combined drainage device and method

A packer, four-channel technology, applied in the directions of sealing/packing, production of fluids, and earth-moving drilling, etc., to achieve the effect of reducing interlayer interference, reducing reservoir damage, and reducing the probability of occurrence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

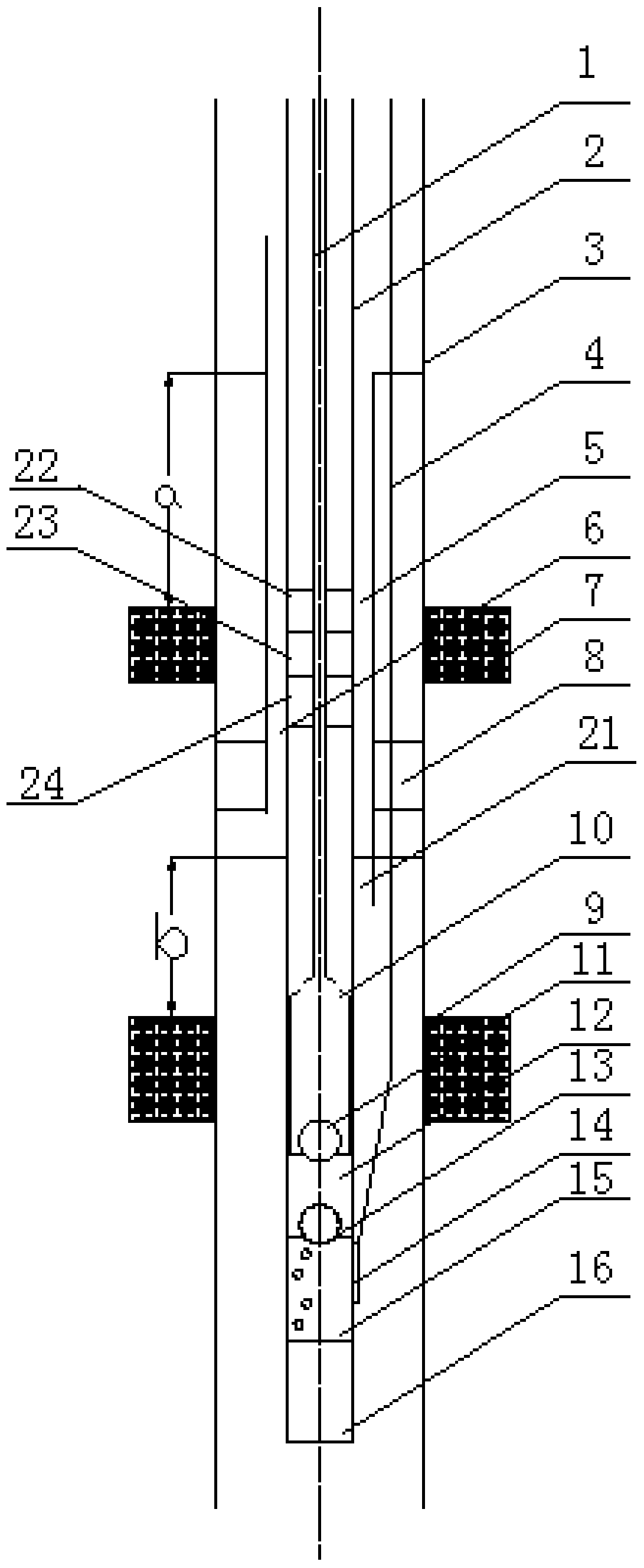

[0027] see Figure 1-2 , shows a coalbed methane well double coal seam four-channel packer layered pressure control combined drainage device of the present invention, which includes oil production strings 2, 12, 15, 16, four-channel packer 8, pressure gauge cable 4 , lower coal seam gas production pipe 6, upper coal seam liquid passage pipe 5, characterized in that:

[0028] The oil production string includes oil pipe 2, pump barrel 12, screen pipe 15, and sand settling pipe 16, and other types of oil production strings can also be selected, such as hydraulic rodless oil production string, jet pump string and hydraulic piston pump pipe column.

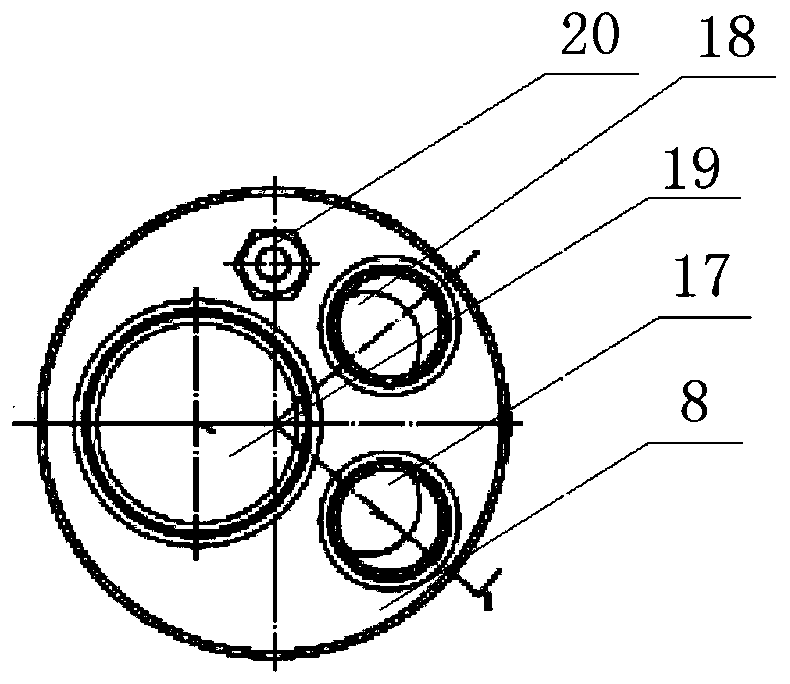

[0029] The four-channel packer 8 is connected with the production string 2 through the upper and lower threads of the main fluid production channel 19 .

[0030] Wherein, the four-channel packer 8 includes a main liquid production channel 19 , a lower coal seam gas production channel 18 , an upper coal seam liquid passage 17 and a ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com