Modularized container building connection joint

A technology for connecting nodes and containers, which is applied in the direction of architecture and building construction, can solve the problems of poor integrity, lack of container connection nodes, and constraints on the development of container buildings, and achieve the effect of ensuring integrity and clear transmission paths of nodes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the drawings.

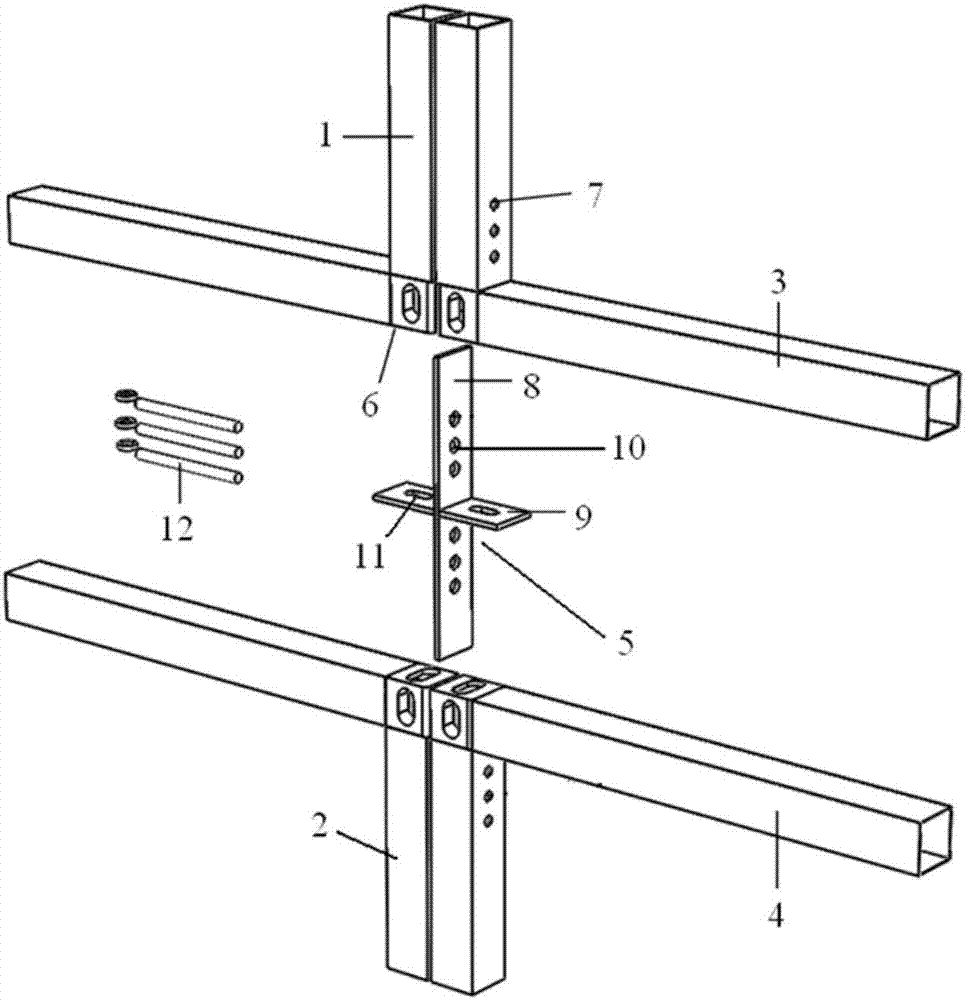

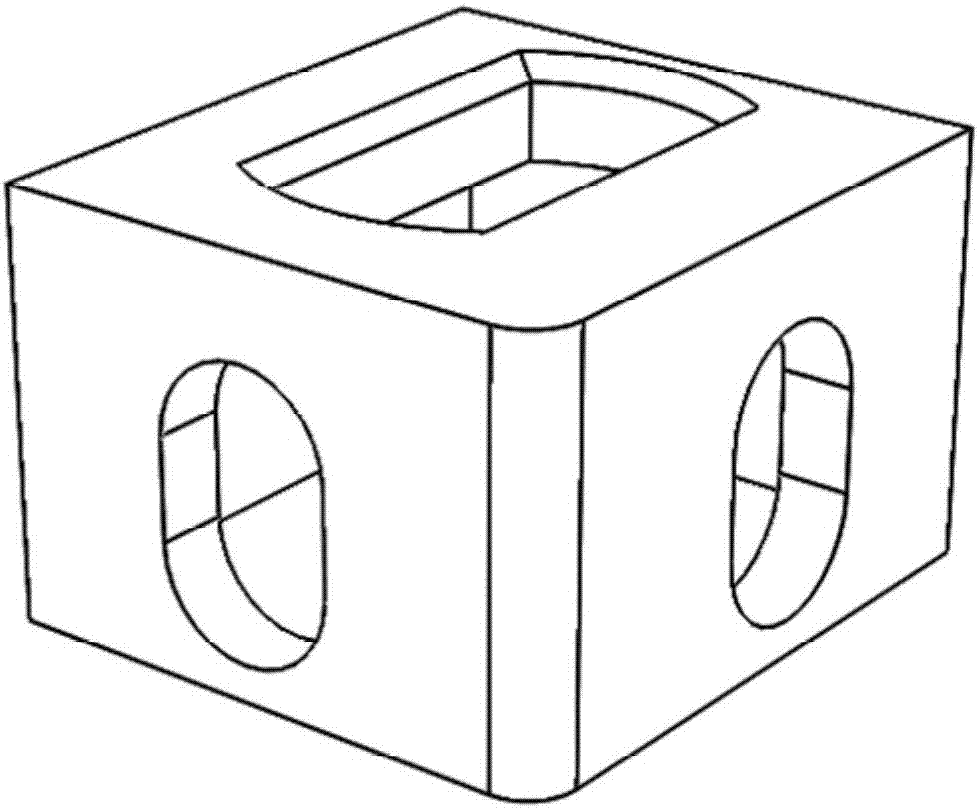

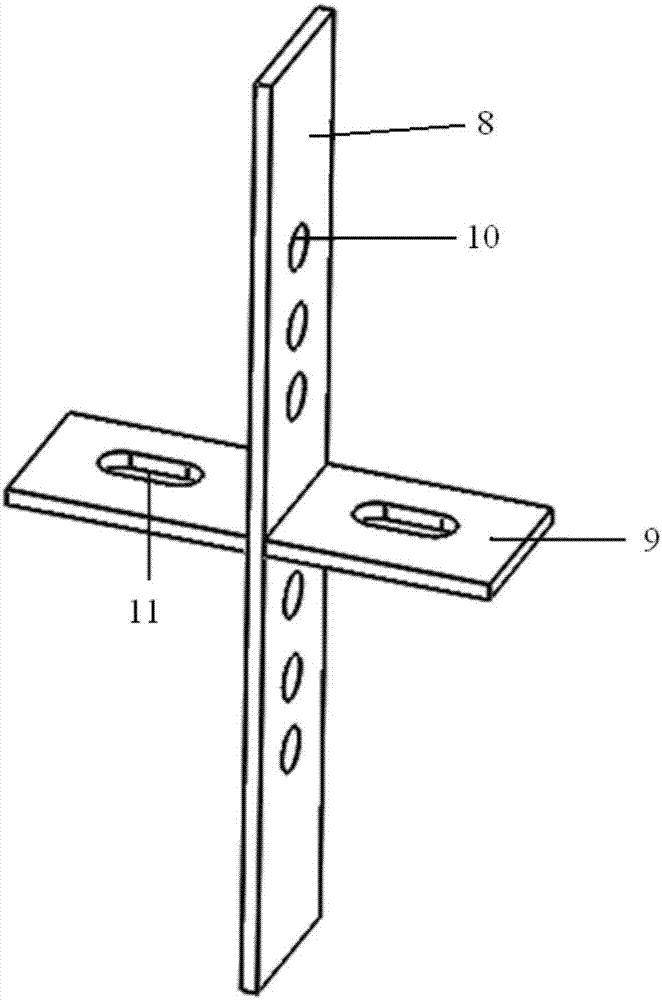

[0020] As attached Figure 1 to Figure 3 As shown, the present invention is a connection node applied to a modular container building for connecting upper and lower module units. The module unit is composed of a frame beam, a frame column and a container corner piece 6. The frame beam and the frame column include Upper module frame column 1, lower module frame column 2, upper module floor beam 3, and lower module ceiling beam 4. The upper module unit and the lower module unit are connected by the cross-shaped gusset plate 5 and the long through bolts 12, and the frame columns rely on the cross-shaped gusset plate 5 and the long through bolts 12 to transmit tensile, shear and bending moments, and the node transmission path Clear, to ensure the joint stiffness and structural integrity.

[0021] The specific implementation process of the present invention is:

[0022] In the factory prefa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com