High salt content organic wastewater treatment device

A technology for organic wastewater treatment and high salt content, applied in multi-stage water treatment, water/sewage treatment, heating water/sewage treatment, etc., can solve the problem of volatile organic compound removal in condensed water, not considered, evaporation chamber The feasibility of heat and moisture transfer solves problems such as structural damage of the evaporation chamber, achieving good application prospects, reducing energy consumption, and facilitating classification and recycling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

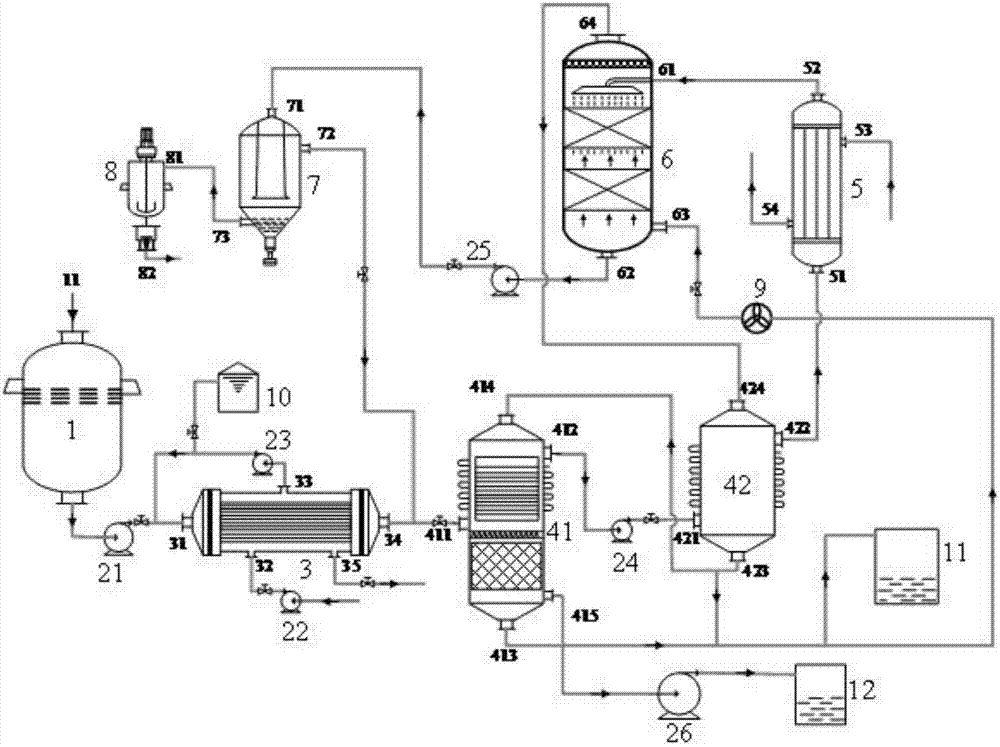

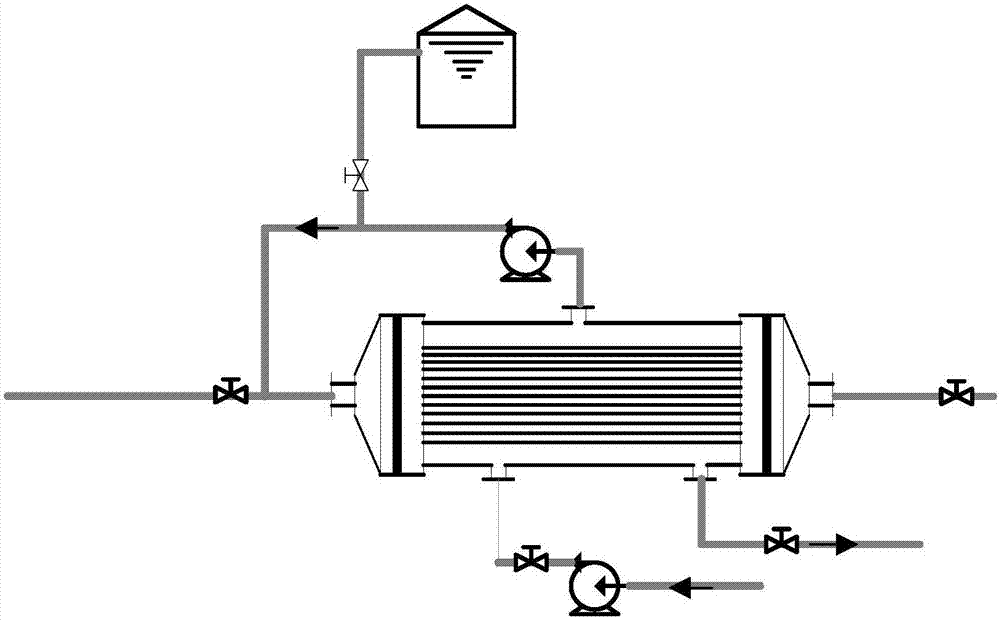

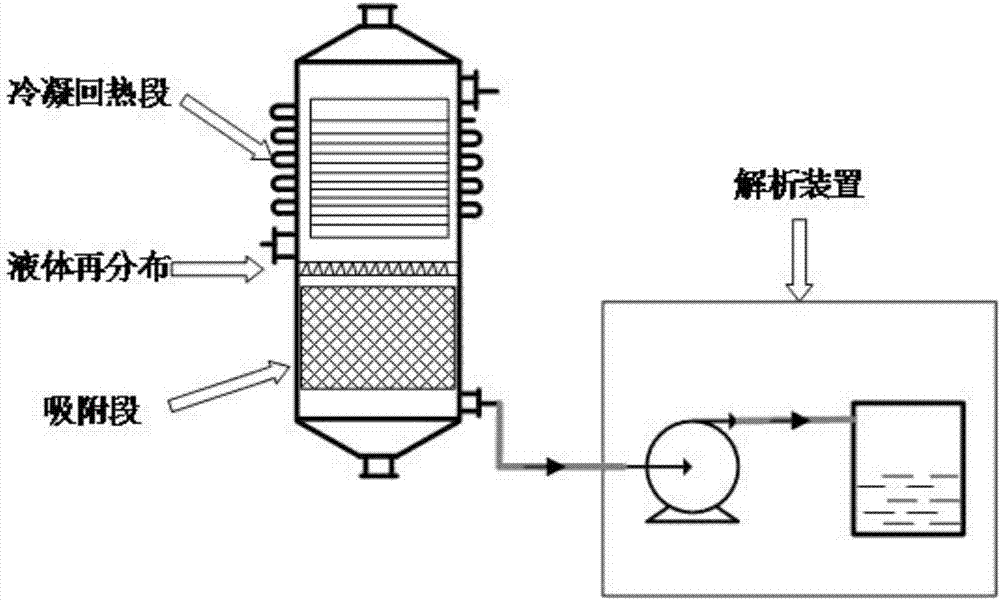

[0039] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. These drawings are all simplified schematic diagrams, and only illustrate the basic structure of the present invention in a schematic manner.

[0040] The new type of high-salt organic wastewater treatment device in this embodiment originally utilizes the characteristics that the temperature of dry air increases, its saturated moisture content increases, and the rate of increase of saturated moisture content increases significantly after 50°C, making full use of the characteristics of air The huge humidity difference brought about by the temperature rise enables the air to absorb the moisture in the waste liquid.

[0041] The condensing sections of the condensing regenerator and the condensing-adsorption regenerator used in the present invention are finned tube heat exchangers with the same size and structure. Activated carbon is selec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com