Novel radial tire

A radial tire, a new type of technology, applied in tire parts, reinforcement layers of pneumatic tires, transportation and packaging, etc., can solve problems such as cord puncture, and achieve the effect of reducing stress and stable and reliable use of the carcass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

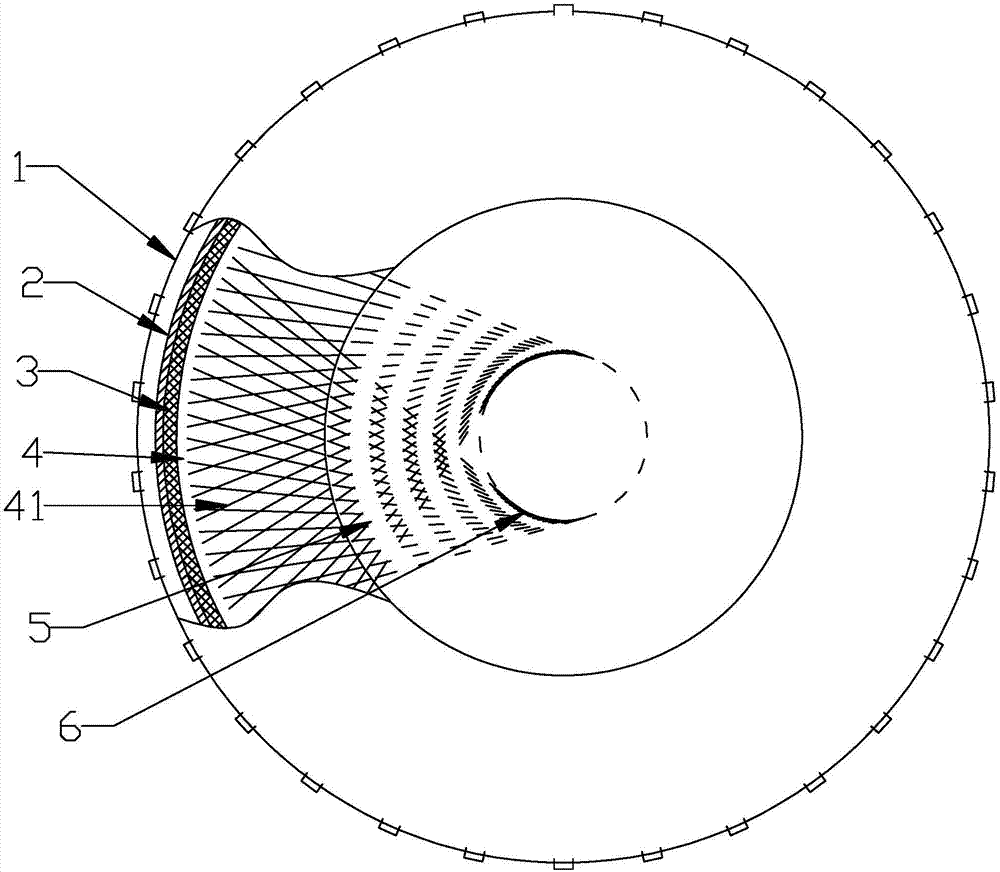

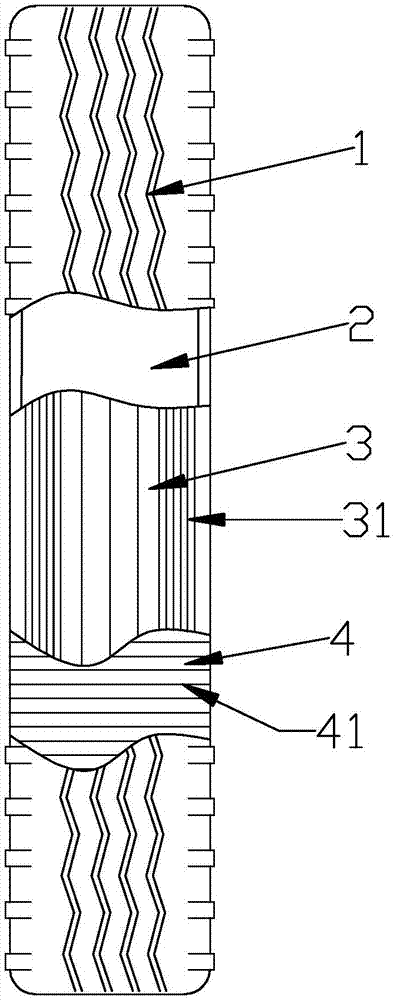

[0016] Such as figure 1 , figure 2 As shown, the present invention is a novel radial tire, which includes a carcass layer 4, a belt layer 3, a protective layer 2 and a crown 1 from inside to outside, and the carcass layer cords 41 are distributed in parallel on one side of the tread. And perpendicular to the circumferential line of the carcass, the projections of the carcass layer cords 41 on the sidewall part cross each other to form a network, and their extension lines 5 (virtual lines) are tangent to a specific point coaxial with the circumferential line of the carcass. Circle 6 (this specific circle is a virtual circle), the diameter of this specific circle is 1 / 3 of the diameter of the carcass inner ring. There are three belt cords, which are wound along the tread side of the carcass at an angle of 3 degrees to the circumferential line of the carcass. The density of the belt layer cords 31 is distributed in such a way that the density is higher on both sides and lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com