Automatic thread binding equipment for paper

A paper and equipment technology, applied in the field of paper automatic thread binding equipment, can solve the problems of lack of economic benefits, inability to use staples, low thread binding efficiency, etc., and achieve fast binding speed, improve efficiency, and improve thread binding efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments of the description:

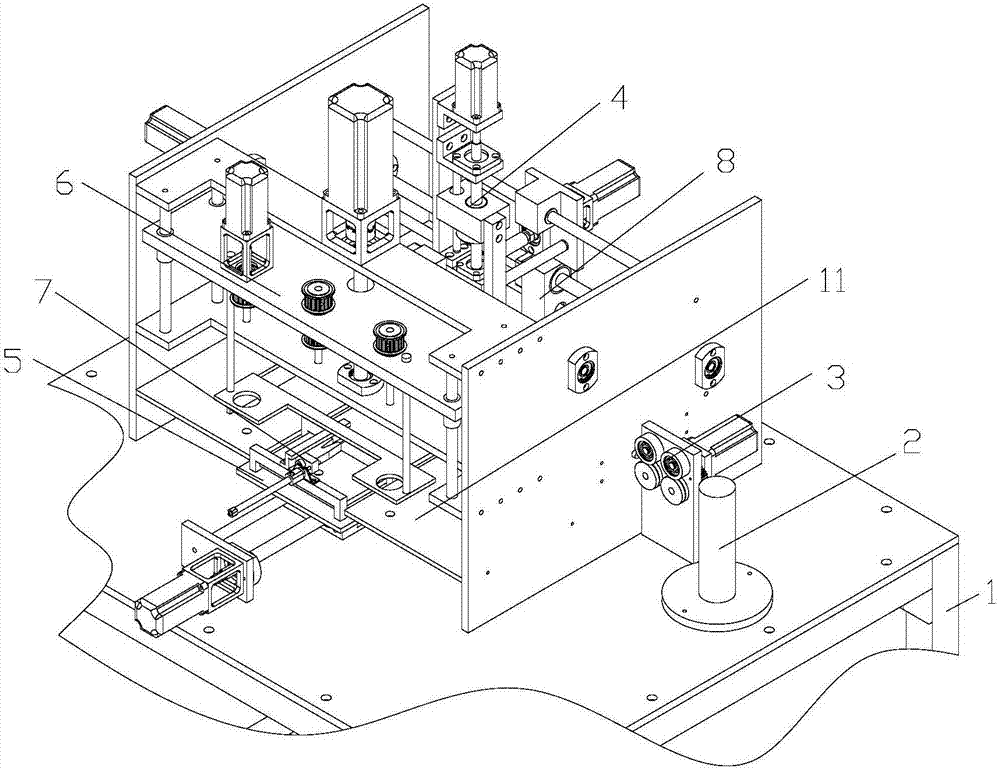

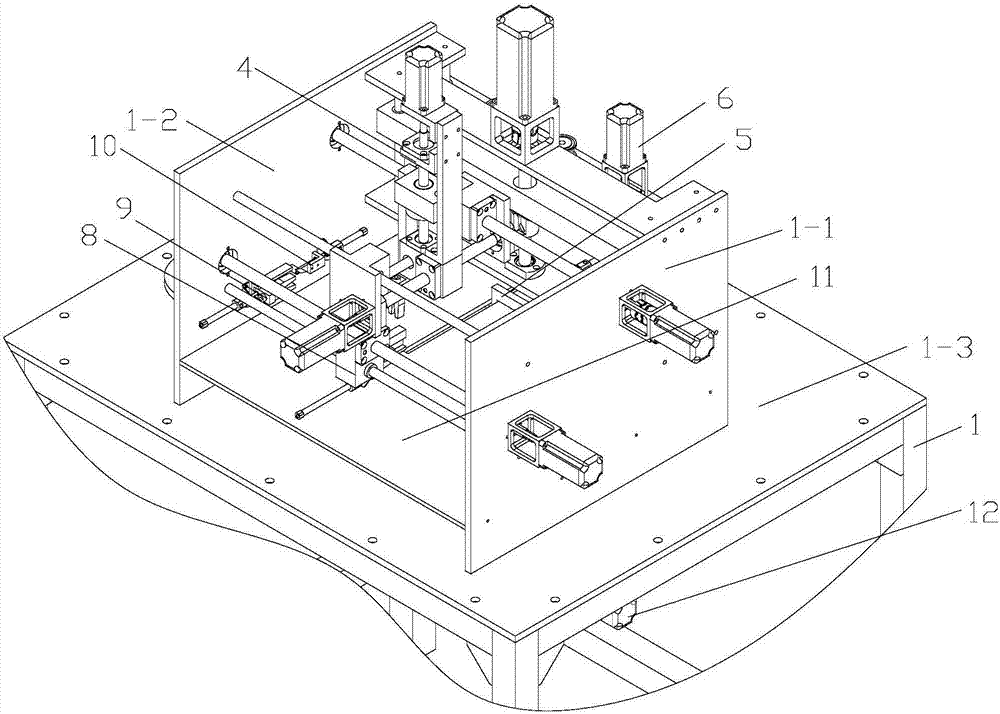

[0059] Such as Figure 1-2 As shown, the present embodiment provides an automatic paper thread-loading device, including a frame 1, a work surface 1-3 arranged on the frame 1, and a left bracket 1-1 fixed above the work surface 1-3 and oppositely arranged And the right bracket 1-2, the cardboard 11 horizontally installed between the left bracket 1-1 and the right bracket 1-2, and the threading knotting assembly installed on the upper and lower sides of the cardboard 11 for cooperating with the threading and knotting action ;

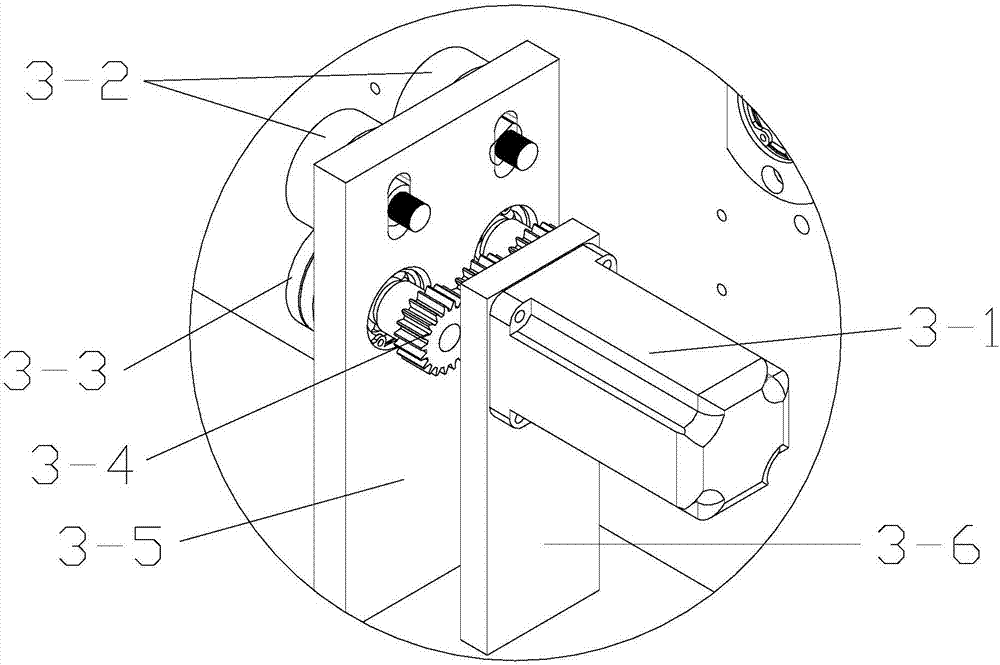

[0060] The front side of the cardboard 11 is provided with a long hole 11-3 that is transparent up and down and extends along the left and right directions to facilitate threading and knotting; the left bracket 1-1 or the right bracket 1-2 is provided with a threading Install the wire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com