Multi-shaft parallel type three-dimensional printer

A parallel, printer technology, applied in the direction of liquid material additive processing, processing drive device, processing and manufacturing, etc., can solve problems such as defective finished products, and achieve the effect of improving printing quality, rapid assembly and installation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The detailed description and technical content of the present invention are described below with accompanying drawings. However, the attached drawings are provided for reference and illustration only, and are not intended to limit the present invention.

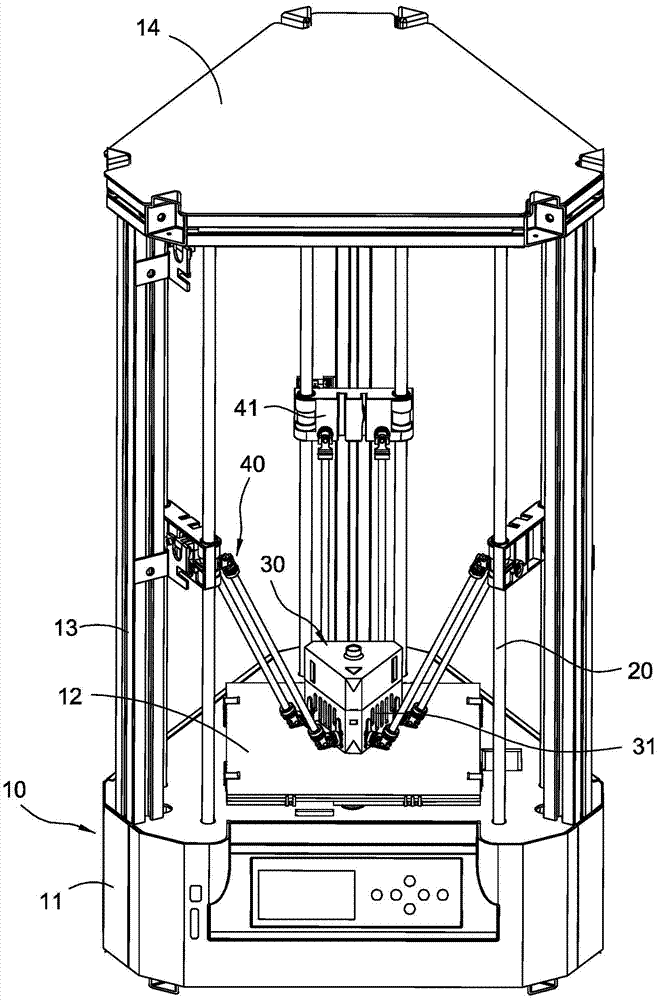

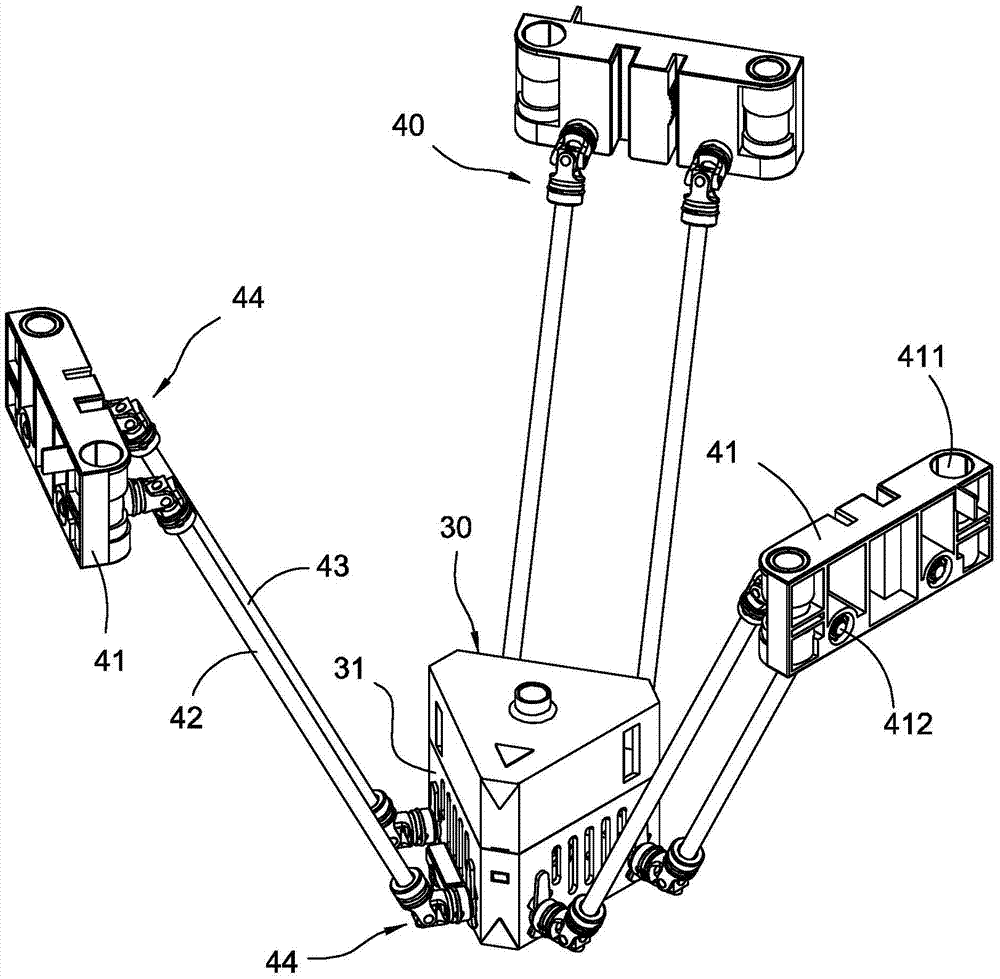

[0054] Please refer to Figure 1 to Figure 3 As shown, the multi-axis parallel 3D printer of the present invention includes a frame 10 , a plurality of vertical shafts 20 , a nozzle module 30 and a plurality of connecting devices 40 .

[0055] The frame 10 includes a nearly triangular base 11, a printing platform 12 is arranged in the middle of the base 11, and a support rod 13 is installed at each corner position of the base 11, and a cover is placed on the top of each support rod 13 A cover plate 14 is provided.

[0056] There are six vertical shafts 20 in this embodiment, each of which is a group of two, and is divided into three groups. Each group of vertical shafts 20 is respectively erected at each corner end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com