High-reliability mechanical gripper mechanism

A mechanical gripper and reliable technology, applied in the direction of manipulators, program-controlled manipulators, conveyor objects, etc., can solve problems such as unstable work, affecting stacking, and low bag grabbing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The technical solutions of the present invention will be further described below in conjunction with the drawings and specific implementations.

[0064] The mechanical gripping mechanism of this embodiment is used as a component of the palletizer of the ceramic tile packaging line. In order to explain this embodiment more clearly, figure 1 , figure 2 with image 3 Both the top plate 3042 of the outer frame body 304 and the side plates 3041 on the left and right sides are hidden; Figure 5 The side plate 3041 in front of the outer frame 304 is hidden.

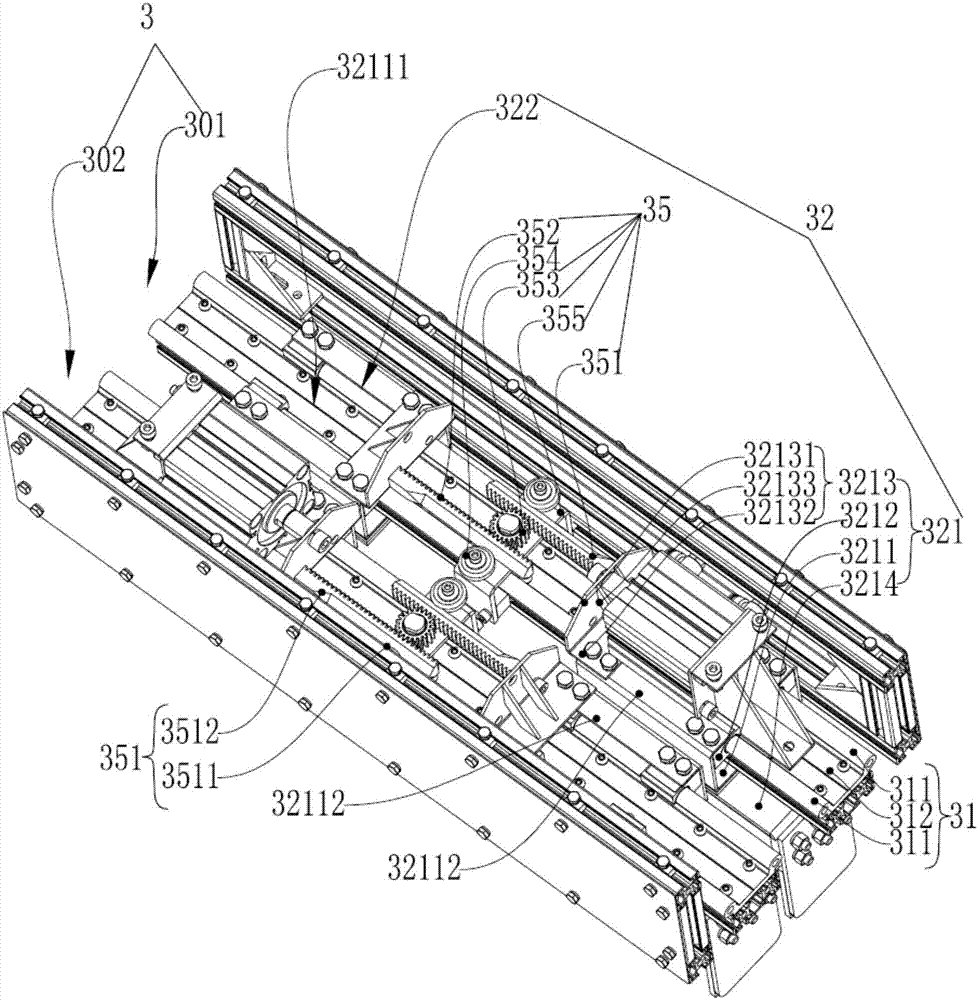

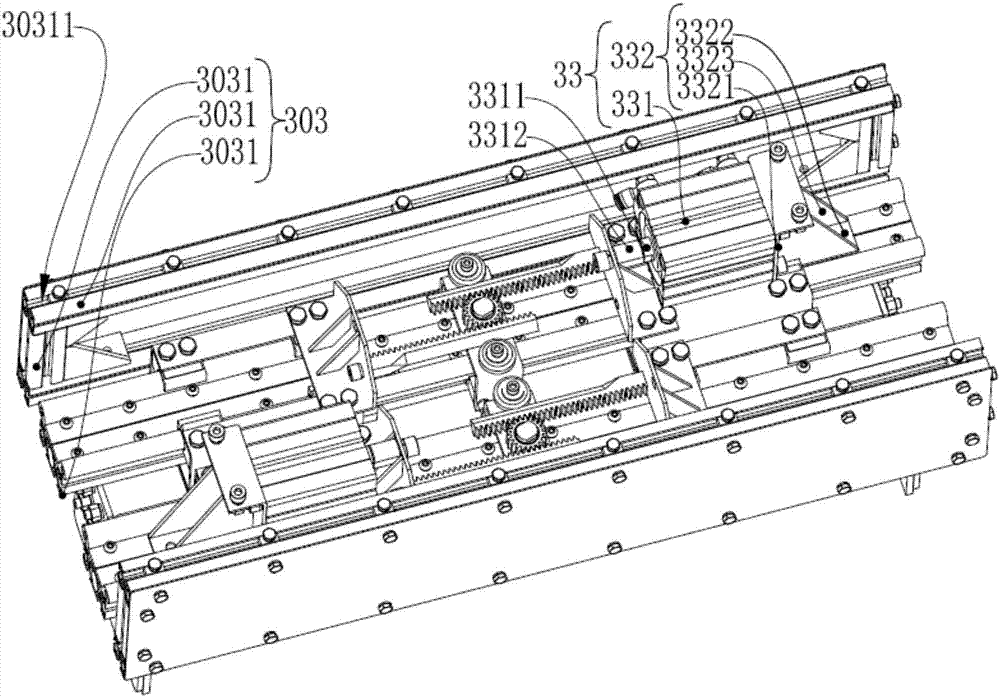

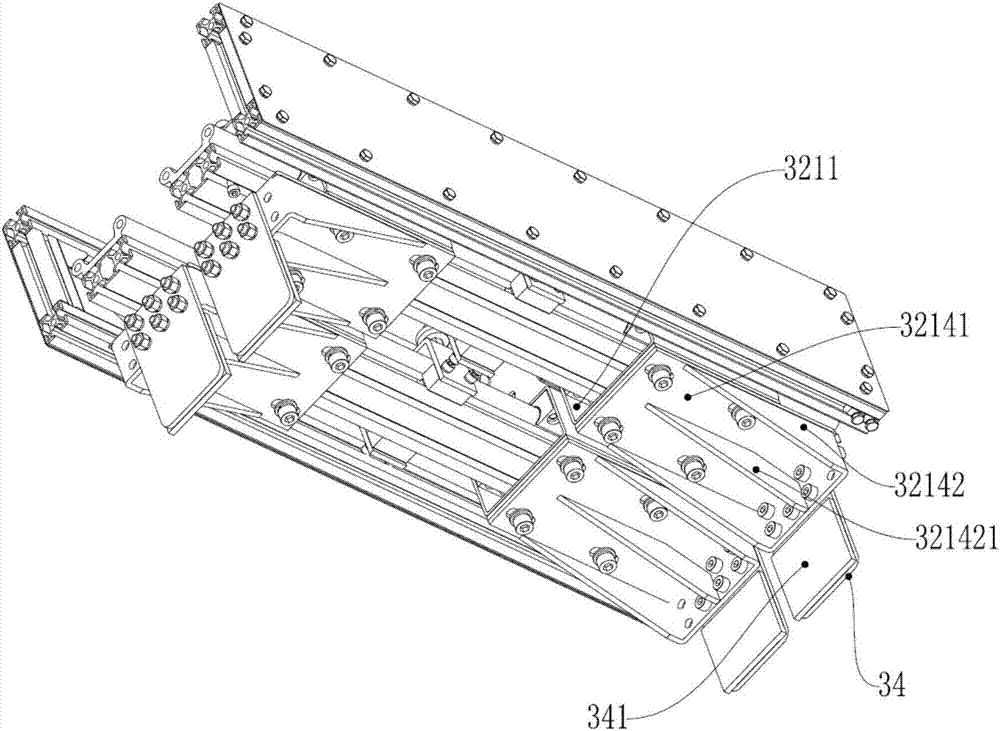

[0065] Such as Figure 1 to Figure 6 As shown, a mechanical gripping mechanism with high reliability includes at least one set of clamping mechanism 3, and the clamping mechanism 3 includes a sliding rail 31, a sliding portion 32, a driving device 33, a grasping plate 34 and a transmission portion 35;

[0066] The sliding portion 32 includes an active sliding portion 321 and a driven sliding portion 322, both of which can be sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com