Condensate water collection device with rotary impeller

A collection device and rotating impeller technology, applied in air heaters, lighting and heating equipment, fluid heaters, etc., can solve the problems of slow flow of condensed water, threats to user safety, exhaust of smoke into the room, etc., and achieve the goal of reducing blockage Possibility, optimization of internal flow channel structure, and enhanced flow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and embodiment the patent of the present invention will be further described.

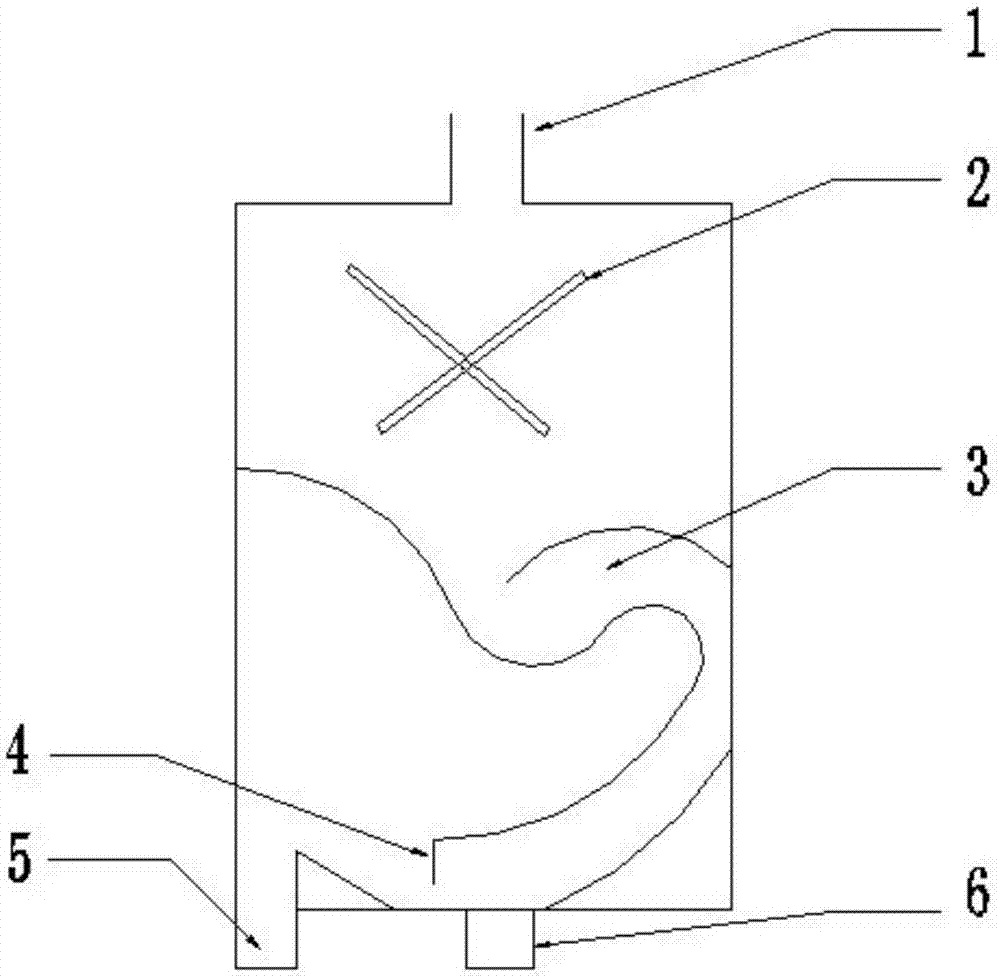

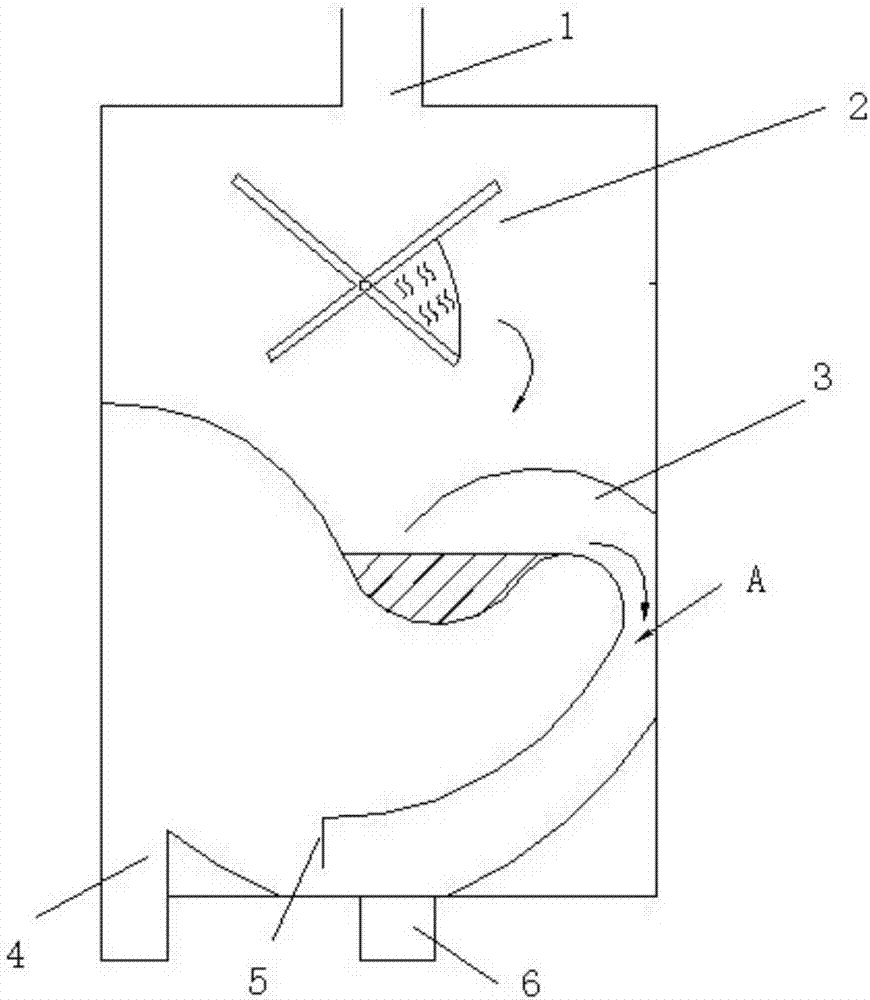

[0016] Such as figure 1 , figure 2 As shown, the heating device of the present invention, such as the condensed water collecting device of the gas water heater, comprises the inlet 1 of the condensed water collecting device on the upper part, the water storage rotating impeller 3 below the inlet 1 of the condensed water collecting device, and its center is the center of the water inlet 1 Offset by about 3-5mm, the middle internal condensed water collection channel and the lower condensed water collection device drain 6, the internal flow channel is an inverted S-shaped siphon structure channel 3, using the siphon principle to strengthen The flow of condensed water enables the condensed water to be collected and discharged reasonably. The top of the device is the inlet 1 of the condensate collection device, and a water seal baffle 4 is added a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com