An electrical connector

An electrical connector, integrated technology, applied in the direction of connection, connecting device components, circuits, etc., can solve the problems of line damage, tedious installation, electrical connector breakdown, etc., to achieve fast installation, and solve the effect of cumbersome terminal installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

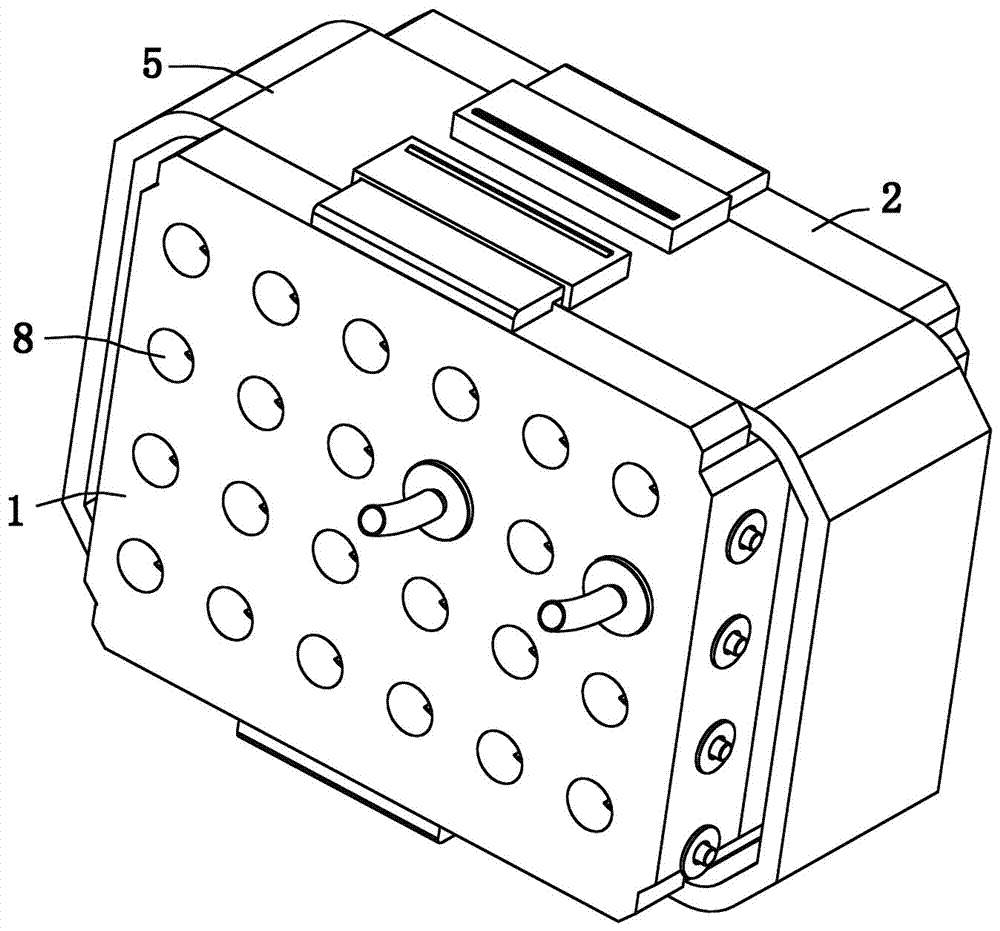

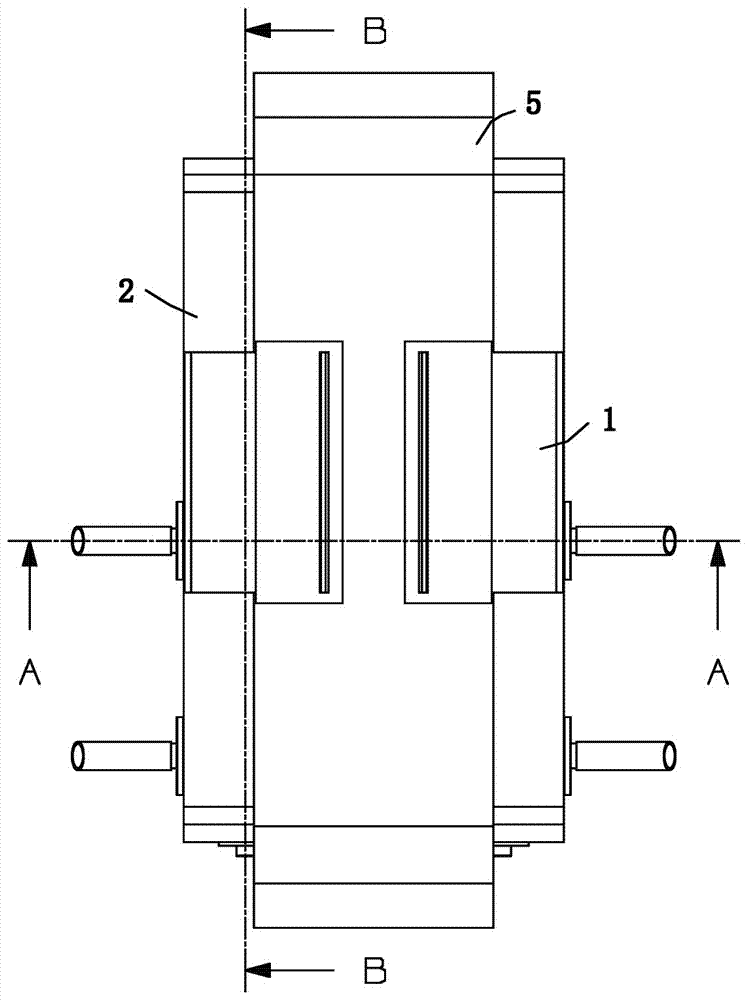

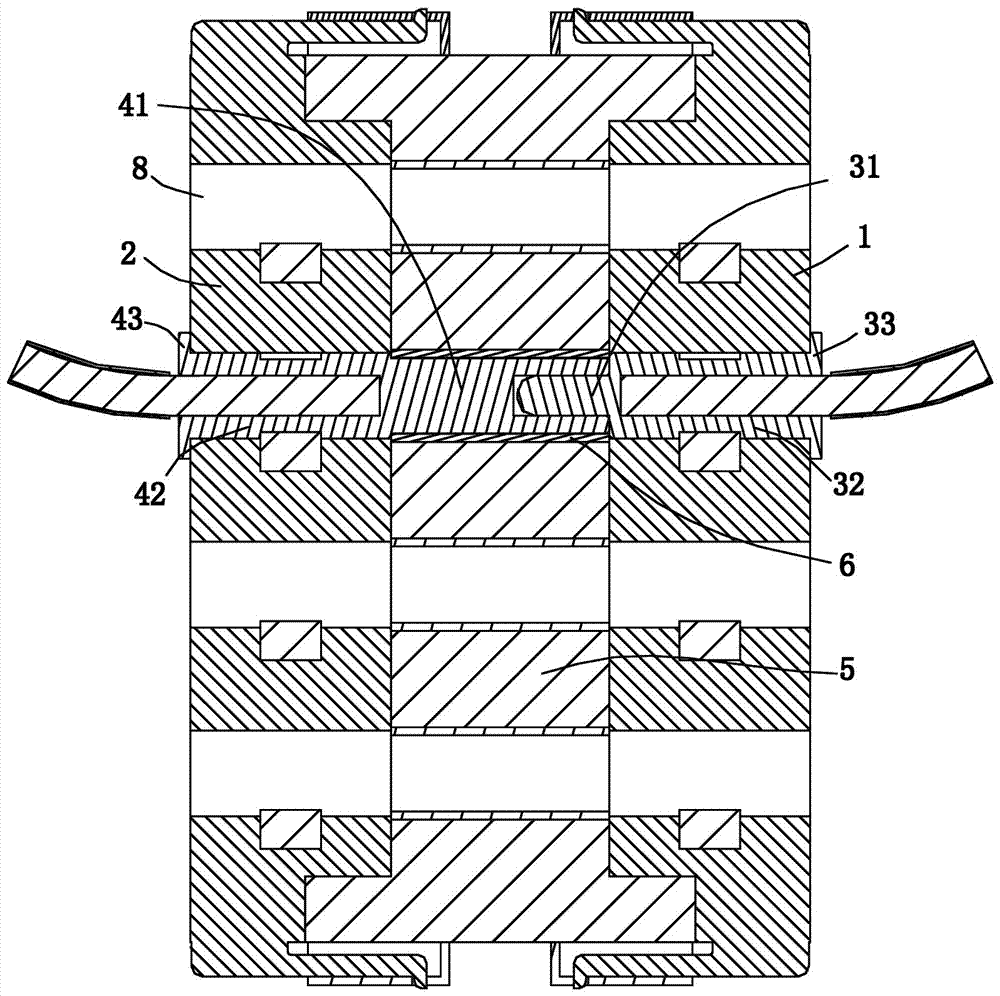

[0026] according to Figure 1 to Figure 8 The shown electrical connector includes a joint and an adapter 5, the joint is provided with a plurality of mounting holes 8, the joint includes a first joint 1 and a second joint 2, and the installation of the first joint 1 A terminal plug 3 is installed in the hole 8, the end of the terminal plug 3 protrudes from the front side wall of the first joint 1, and a terminal socket 4 is installed in the installation hole 8 of the second joint 2, and the terminal socket 4 The end protrudes from the front side wall of the second joint 2; the adapter 5 is provided with a plurality of through holes, and a ring-shaped protective plate 6 coaxial with the through hole is provided in the through hole, and the protective plate 6 is Made of insulating material, the outer peripheral wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com