Packing type energy-saving oil production pump

A technology for oil production pumps and packers, which is applied in the direction of pumps, production fluids, earthwork drilling and production, etc. It can solve the problems of high power pumping units and lack of energy-saving functions, and achieve energy-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

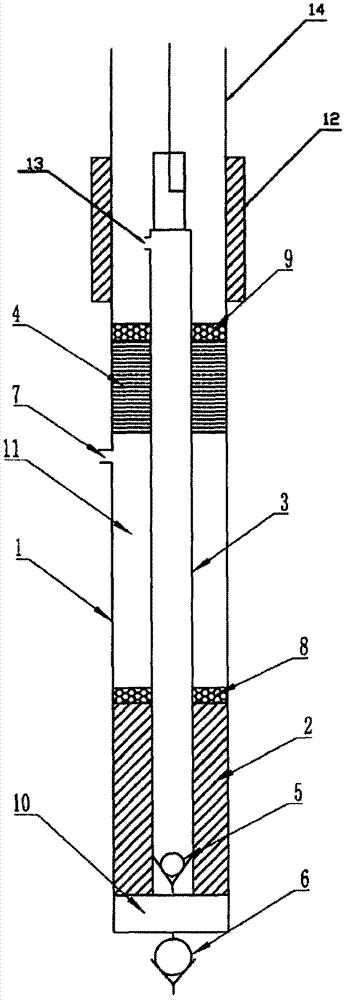

[0015] Such as figure 1 As shown, a pack-type energy-saving oil production pump includes a pump barrel 1, a hollow plunger 2, a hollow sucker rod 3 and a packer 4. The pump barrel 1 is a cylindrical structure and is vertically arranged, and its bottom end is arranged There is a fixed one-way valve 5, and the top of the pump cylinder 1 is connected with an oil pipe 14.

[0016] The hollow plunger 2 is cylindrical and has a through hole along its central axis; the hollow plunger 2 is arranged in the pump barrel 1 and is slidably connected with the pump barrel 1 (the hollow plunger 2 can slide up and down in the pump barrel 1 ). The length of the hollow plunger 2 is much shorter than the length of the pump cylinder 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com