Stereoscopic rotary feeding device

A feeding device, three-dimensional technology, applied in conveyor control device, stacking, transportation and packaging of objects, etc., can solve the problem of unutilized space, large area, and the inability to implement the project plan of the production line occupied by the feeding device, etc. problems, to achieve the effect of saving workplace area, reducing feeding frequency, reducing labor intensity and assisting feeding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing:

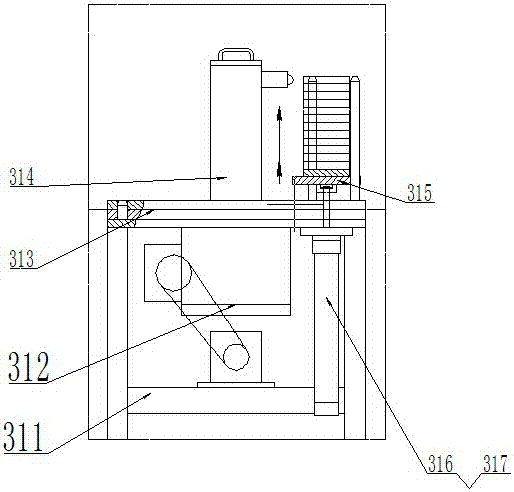

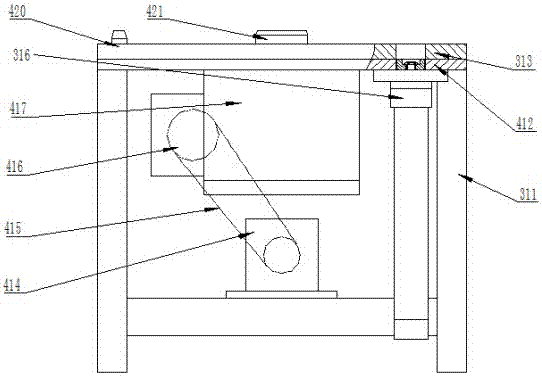

[0028] Such as figure 1 , figure 2 and Figure 4 As shown in the three-dimensional rotary feeding device, the rotary platform 313 is installed on the rotary platform 412 of the rotary platform bracket 311, the rotary platform 313 is connected to the rotary platform driving part 312, and the rotary platform 313 is driven by the rotary platform driving part 312 to rotate around the center, and the parts are rotated around the center. The turntable 314 is installed on the turntable 313 through the positioning shaft 421, and rotates together with the turntable 313. The lifting cylinder 316 and the lowering cylinder 317 are installed under the turntable 313; , lifting cylinder 316, descending cylinder 317 to drive the lifting of the tray 315 of the parts turntable, the lifting or lowering position is signaled by the workpiece monitoring 318 and the processed workpiece monitor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com