Bridge bottom surface coating device and construction method thereof

A bridge and bottom surface technology is applied to the paint spraying device for the bridge wall and its construction field, which can solve the problems of high risk, physical injury of construction workers, unsatisfactory construction speed and quality, etc. , the effect of increased rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

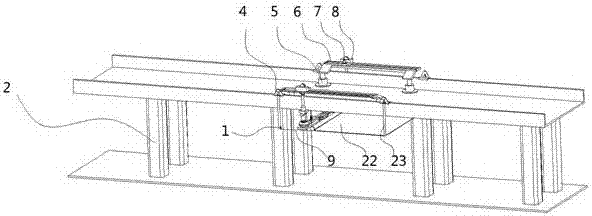

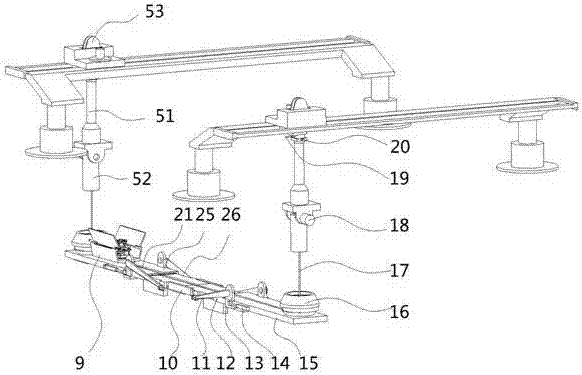

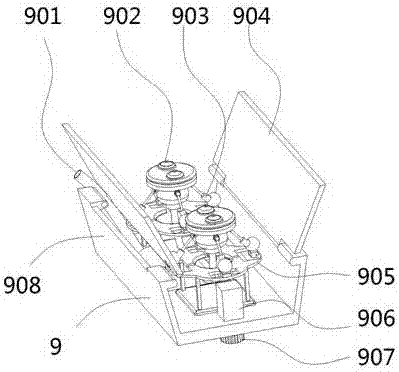

[0025] As shown in the figure, the bridge bottom surface coating device includes a slide rail groove-6 erected on the side wall of the bridge, and the two ends of the slide rail groove-6 are supported by jacks 5, and the slide rail groove-6 is equipped with The motor 7 drives the slider 8 to move back and forth on it.

[0026] The bottom of slide block 8 is connected with upper pipe cover 51, and described upper pipe cover 51 is hingedly connected with lower pipe cover 52, and the side of institute's upper pipe cover 51 is equipped with driving lower pipe cover 52 rotating motor two 18; 8, a wire rope retractable machine 53 is installed above; the steel wire rope 17 passes through the upper pipe sleeve 51 and the lower pipe sleeve 52, and one end is connected with the wire rope retractable machine 53, and the other end is connected with a slot seat 16; There are slotted holes for the lower sleeve 52 to be inserted. The device below is that the wire rope retractor 53 controls ...

Embodiment 2

[0038] As shown in the figure, the bridge bottom surface coating device includes a slide rail groove-6 erected on the side wall of the bridge, and the two ends of the slide rail groove-6 are supported by jacks 5, and the slide rail groove-6 is equipped with The motor 7 drives the slider 8 to move back and forth on it.

[0039] The bottom of slide block 8 is connected with upper pipe cover 51, and described upper pipe cover 51 is hingedly connected with lower pipe cover 52, and the side of institute's upper pipe cover 51 is equipped with driving lower pipe cover 52 rotating motor two 18; 8, a wire rope retractable machine 53 is installed above; the steel wire rope 17 passes through the upper pipe sleeve 51 and the lower pipe sleeve 52, and one end is connected with the wire rope retractable machine 53, and the other end is connected with a slot seat 16; There are slotted holes for the lower sleeve 52 to be inserted. The device below is that the wire rope retractor 53 controls ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com