Mooring hole local structure strength testing mechanism

A local structure and strength test technology, applied in the direction of strength characteristics, measuring devices, instruments, etc., can solve the problems of fixed and non-adjustable test angles, and achieve the effect of avoiding repeated replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

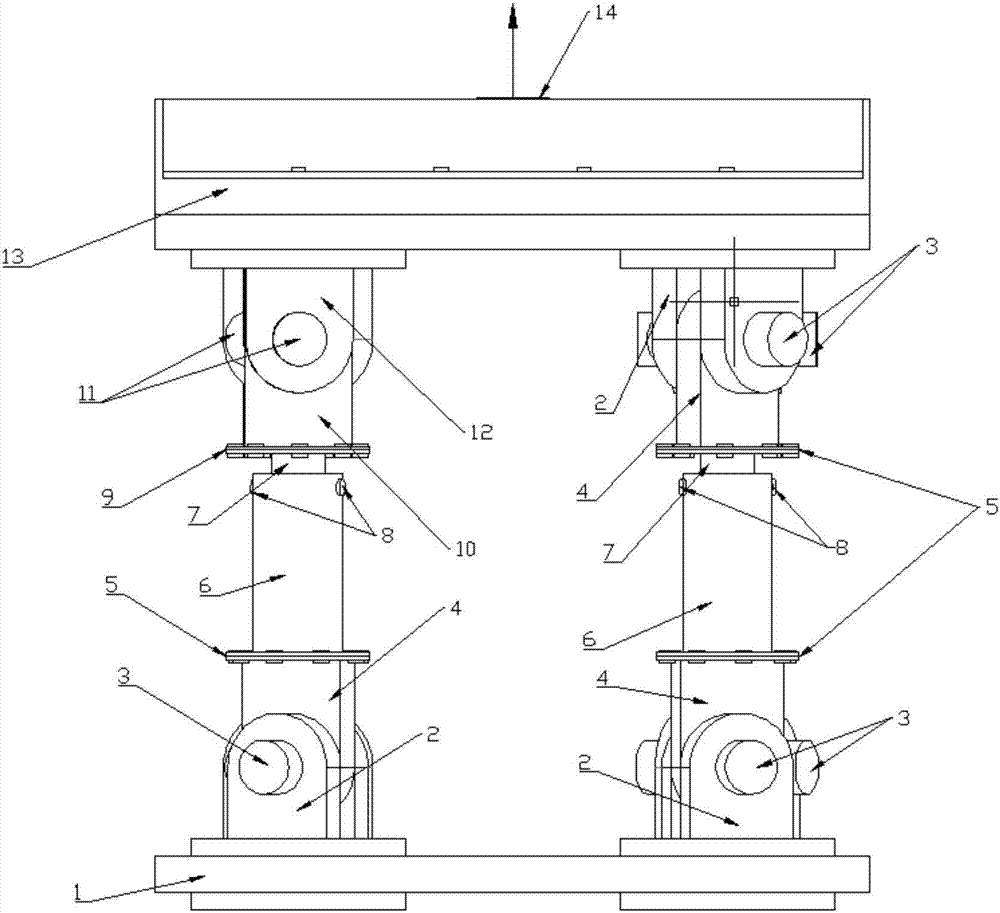

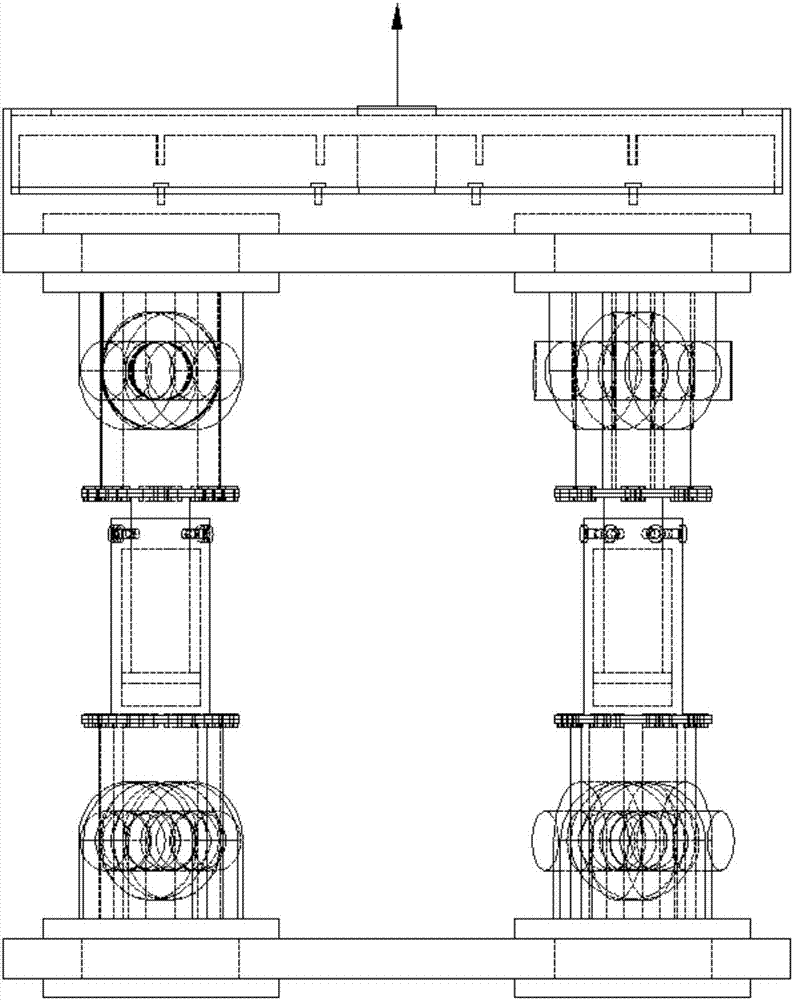

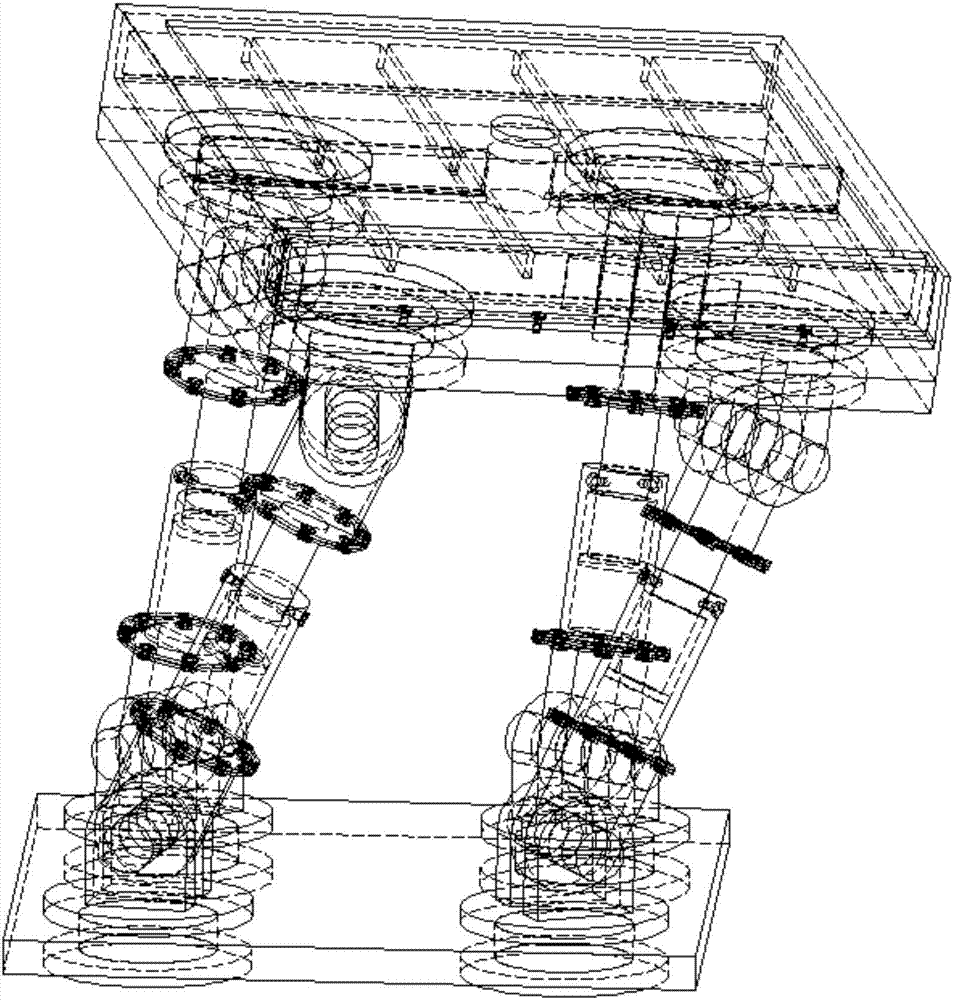

[0025] The patent of the present invention relates to a local structural strength test mechanism of the mooring hole, including: support 1, double ear runner (bottom) 2, latch (bottom) 3, single ear (bottom) 4, flange plate (bottom) 5 , sleeve 6, adjusting rod 7, thimble 8, flange (upper) 9, single ear (upper) 10, latch (upper) 11, double ear runner (upper) 12, clamp 13, hole plate with tie The frame is composed of 14. The support 1 is a fixed support, and four round holes of the same size are opened at the four corners. The binaural wheel (lower) 2 of the test mechanism is a combined structure of a binaural structure and an I-shaped wheel, and can rotate in the above-mentioned support 1. The above-mentioned two-ear runner (lower) 2 is connected with the single ear (lower) 4 through the latch (lower) 3, and can rotate around the above-mentioned latch (lower) 3. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com