Anti-clogging engine oil filter for automobile

An oil filter and anti-clogging technology, which is applied in the field of filters, can solve the problems of affecting the performance and service life of the engine, easy to block the filter screen, and low filtration efficiency of the filter, so as to improve the filtering effect and reduce the filtering pressure , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

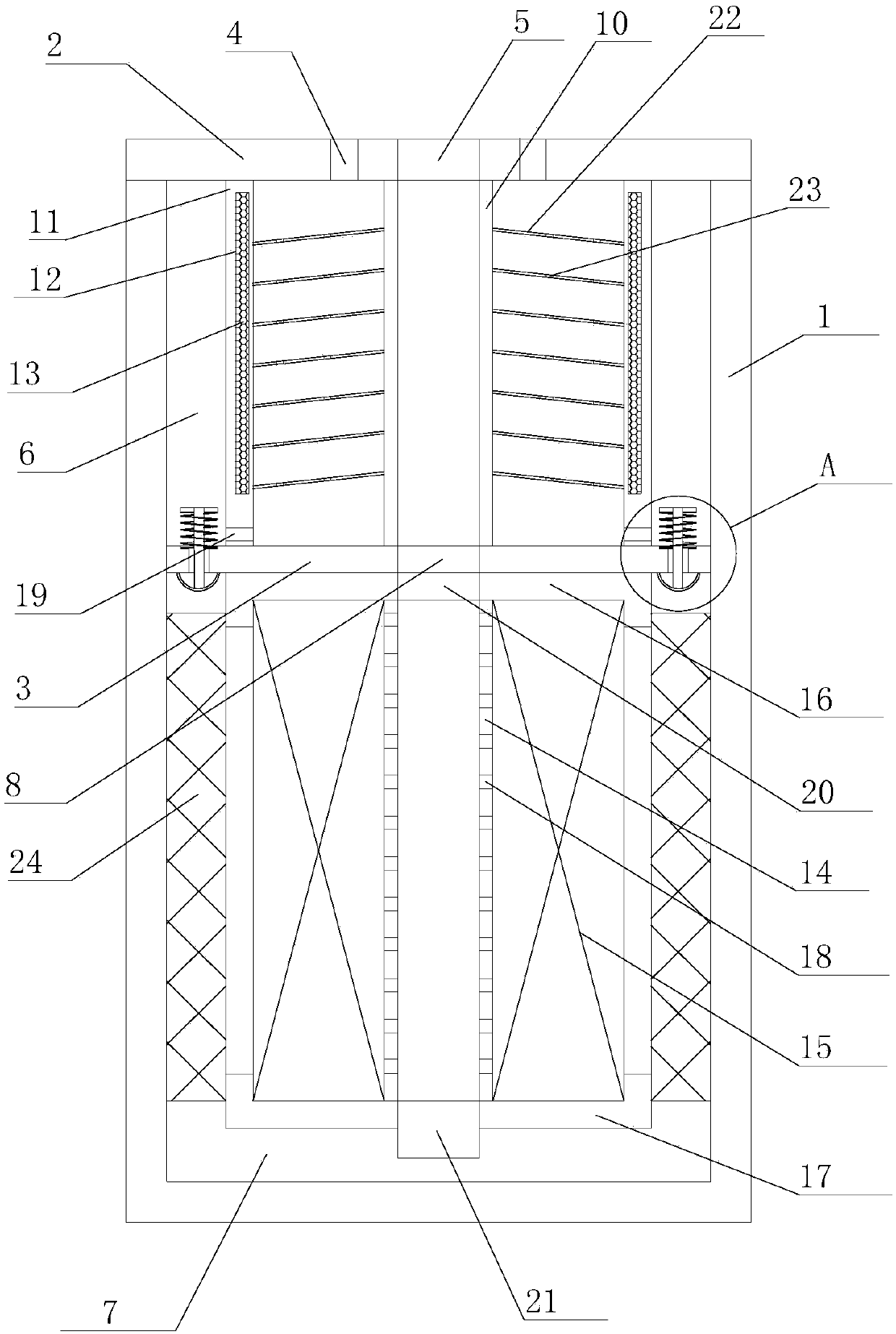

[0018] refer to figure 1 , figure 2 , the present invention proposes an anti-clogging oil filter for automobiles, comprising a housing 1, a base plate 2, a diaphragm 3, a controller, a detector and an alarm, wherein:

[0019] The casing 1 is a cylindrical structure with one end open, the bottom plate 2 cooperates with the opening end of the casing 1 to seal the casing 1 , and the bottom plate 2 is provided with an oil inlet 4 and an oil outlet 5 .

[0020] The diaphragm 3 is arranged inside the housing 1, and the diaphragm 3 divides the interior of the housing 1 into a first filter chamber 6 and a second filter chamber 7, and the diaphragm 3 is provided with a filter connecting the first filter chamber 6 and the second filter chamber. The first oil guide port 8 of the second filter chamber 7 and a plurality of first through holes 9 communicating with the first filter chamber 6 and the second filter chamber 7 . A plurality of first through holes 9 are provided with a backflo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com