Spiral stirrup reinforcing structure for reinforced concrete column and construction method thereof

A technology for reinforced concrete columns and spiral stirrups, which is applied to columns, piers, pillars, etc., can solve the problems of slow construction speed, durability of reinforcement materials, heavy workload of wet work on construction sites, and complicated construction procedures, and achieves simple and fast speed. Reinforcement, reinforcement effect guarantee, fast construction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

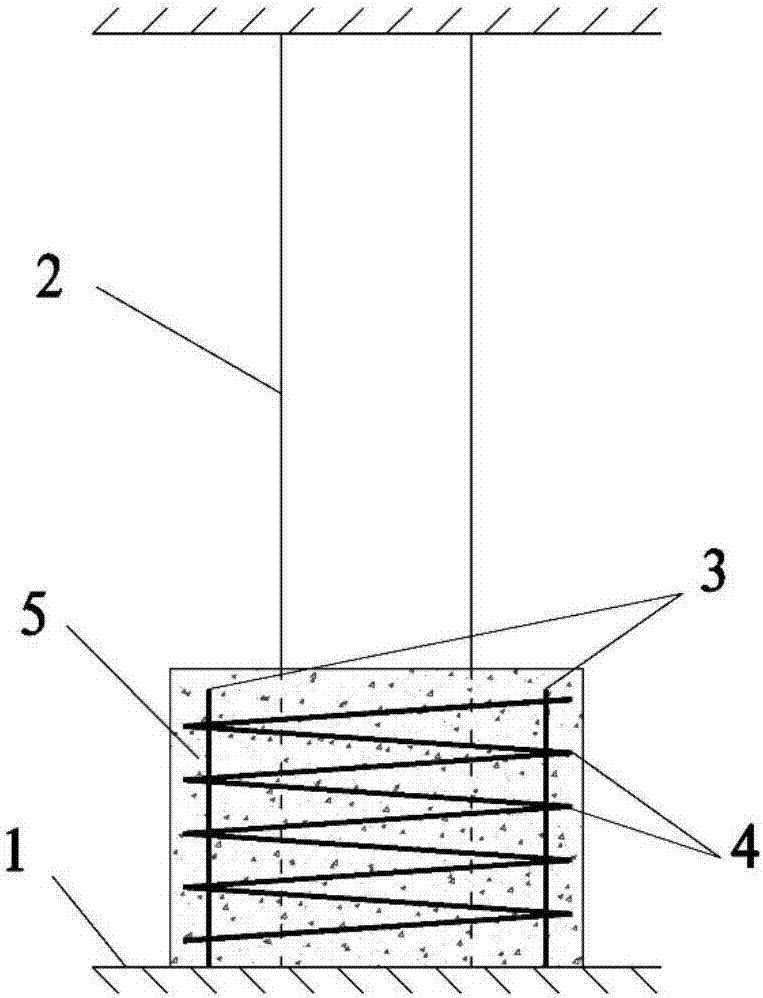

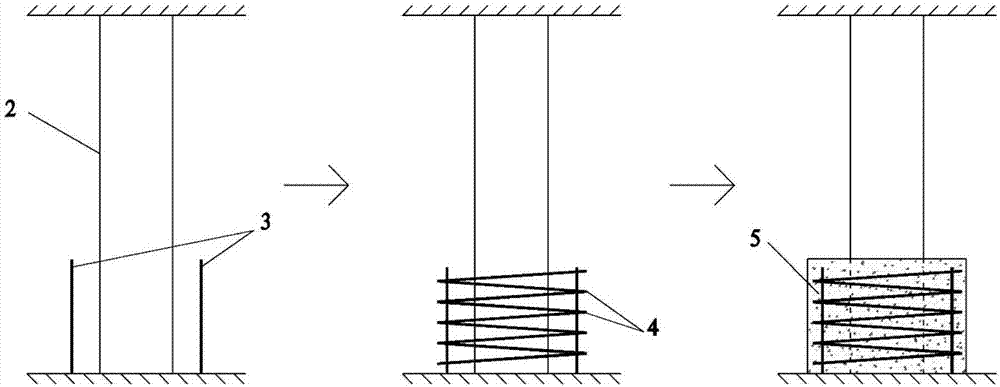

[0032] see figure 1 and figure 2 As shown, the embodiment of the present invention provides a reinforced concrete column reinforced structure with spiral stirrups, including a reinforcement cage and a concrete layer 5 .

[0033] Wherein, the reinforced concrete column 2 to be reinforced is cylindrical, the height of the reinforcement cage is equal to the length of the plastic hinge area at the bottom of the reinforced concrete column 2 to be reinforced, and the height of the reinforcement cage is 1.5 times the cross-sectional diameter of the reinforced concrete column 2 , the reinforcement cage includes spiral stirrups 4 and eight vertical longitudinal reinforcements 3 , and the vertical longitudinal reinforcements 3 are distributed in a circular array around the longitudinal centerline of the reinforced concrete column 2 . The vertical longitudinal bar 3 is located inside the spiral stirrup 4, and the spiral stirrup 4 is bound and connected with the vertical longitudinal ba...

Embodiment 2

[0040] see figure 1 and figure 2 As shown, the embodiment of the present invention provides a reinforced concrete column reinforced structure with spiral stirrups, including a reinforcement cage and a concrete layer 5 .

[0041] Wherein, the reinforced concrete column 2 to be reinforced is a cuboid shape, the height of the reinforcement cage is equal to the length of the plastic hinge area at the bottom of the reinforced concrete column 2 to be reinforced, and the height of the reinforcement cage is the maximum side length of the cross section of the reinforced concrete column 2 1.5 times, the reinforcement cage includes spiral stirrups 4 and eight vertical longitudinal reinforcements 3, and the vertical longitudinal reinforcements 3 are distributed in a circular array around the longitudinal centerline of the reinforced concrete column 2. The vertical longitudinal bar 3 is located inside the spiral stirrup 4, and the spiral stirrup 4 is bound and connected with the vertical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com