Stacking and transferring device of paperboard collecting machine

A transfer device and cardboard technology, which is applied in the direction of stacking receiving device, transportation and packaging, packaging, etc., can solve the problems of time-consuming and labor-intensive, increased production costs, inconvenient cardboard automation development, etc., to achieve convenient implementation, low cost, and save intermediaries The effect of the connection process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

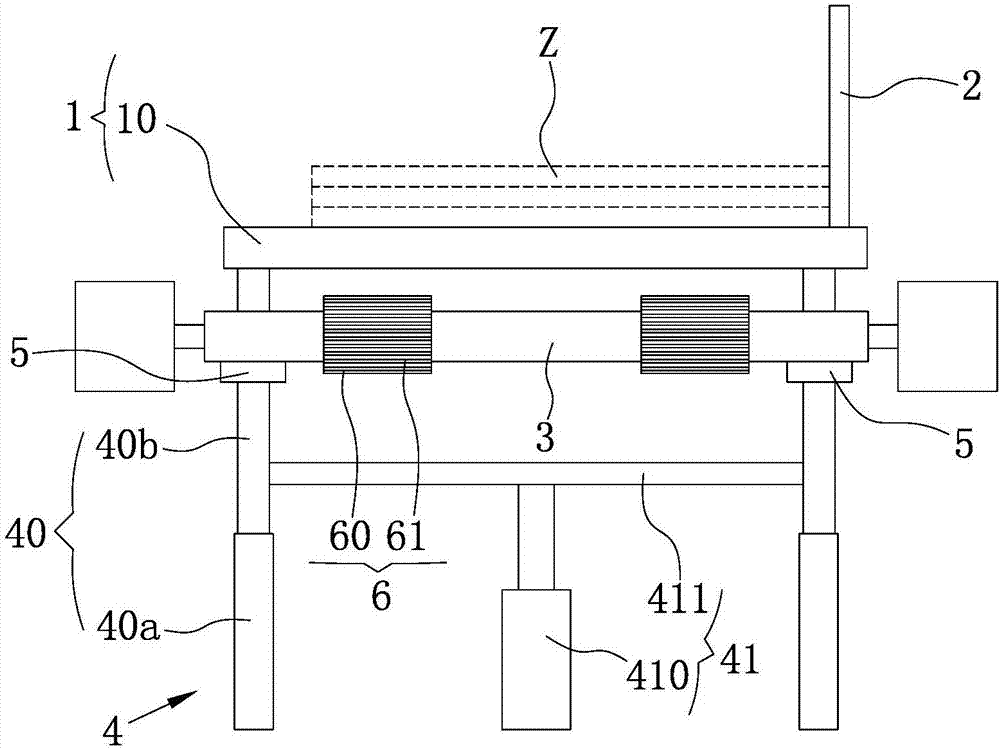

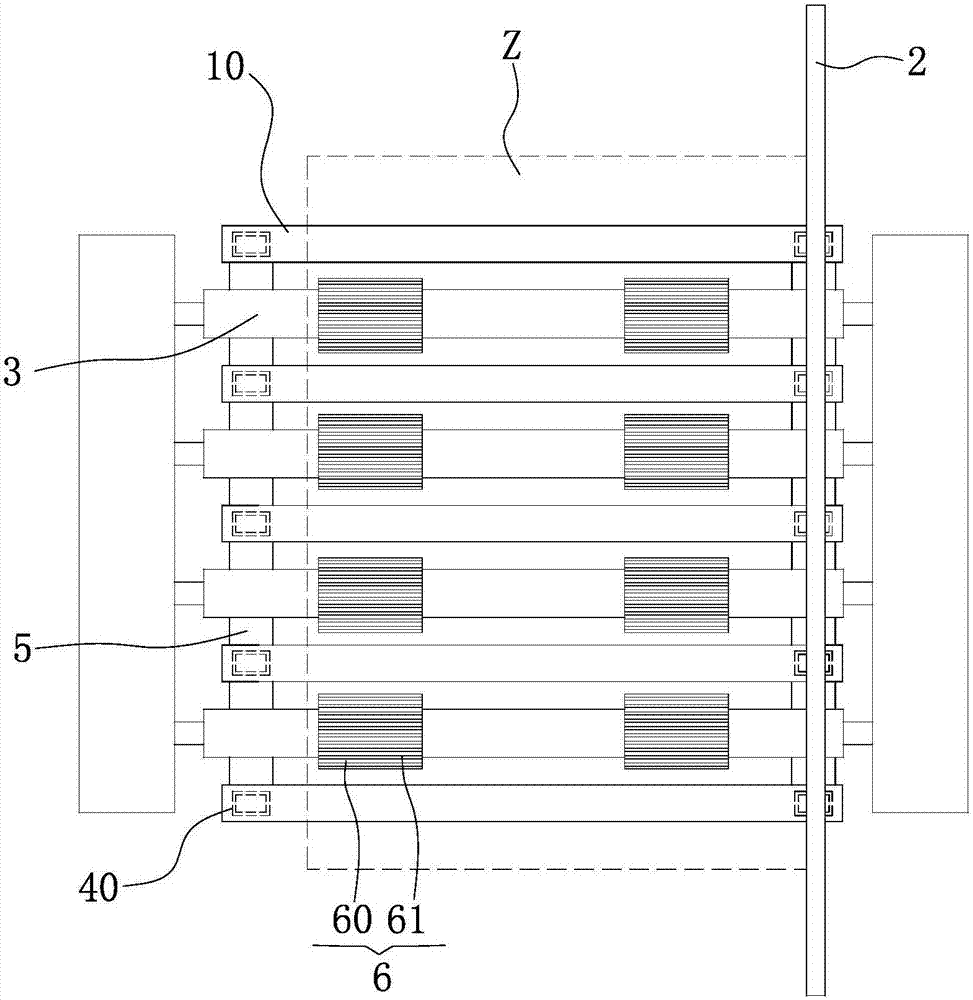

[0029] Such as figure 1 and figure 2 As shown, the stacking and transferring device of the cardboard collecting machine provided in this embodiment includes a stacking frame 1 and a grid plate 2 arranged at the output end of the cardboard conveying device (not shown in the figure), wherein the stacking frame 1 It includes a plurality of support rods 10 extending along the direction of the cardboard conveying device and the upper surface is flush, and the plurality of support rods 10 are arranged at intervals, and the grid plate 2 is located at the end of the support rods 10 away from the cardboard conveying device (in the figure The left end of the support rod 10 is in contact with the cardboard conveying device, and the grid plate 2 is arranged above the right end of the support rod 10), and the stacking transfer device also includes a plurality of The transmission roller 3 , the driving mechanism 4 for driving the plurality of support rods 10 to move along the vertical dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com