Needle rod clutching mechanism of sewing machine and double-needle machine

A clutch mechanism and sewing machine technology, applied in the field of sewing, can solve the problems of increasing the needle bar separation operation steps, the double needle machine cannot work normally, the electromagnet is easy to heat and burn out, etc., and achieve high sewing efficiency and quality, simple structure, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

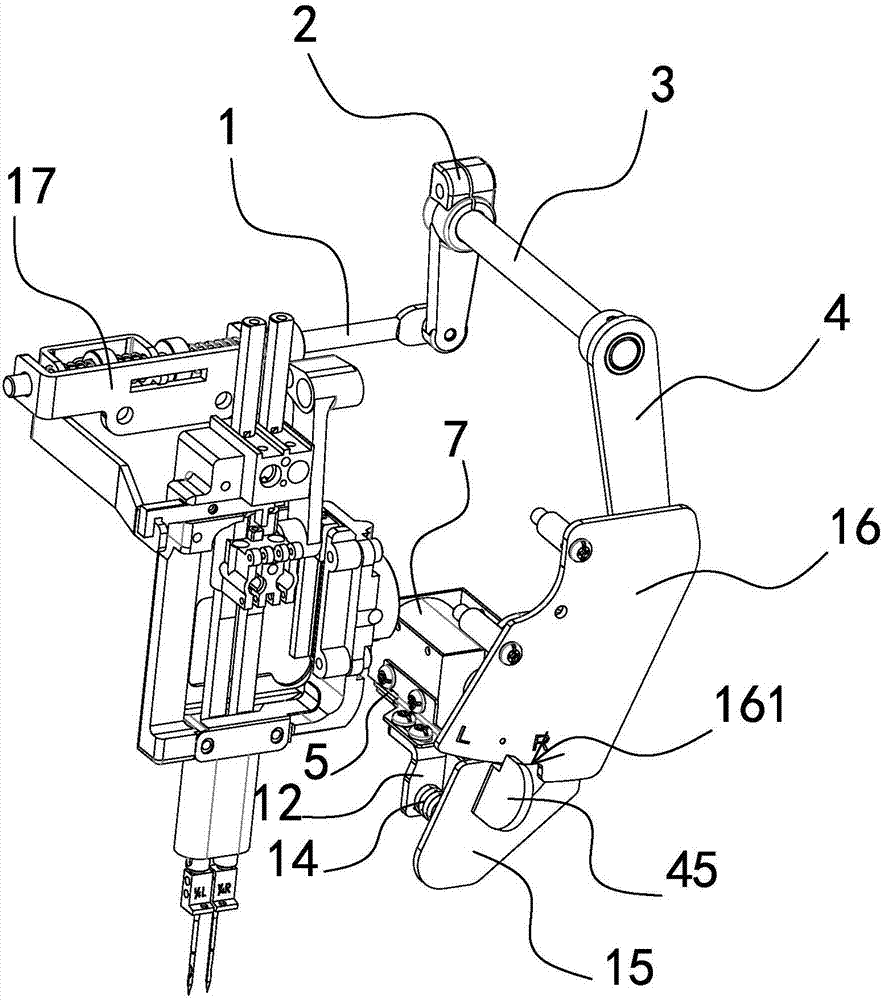

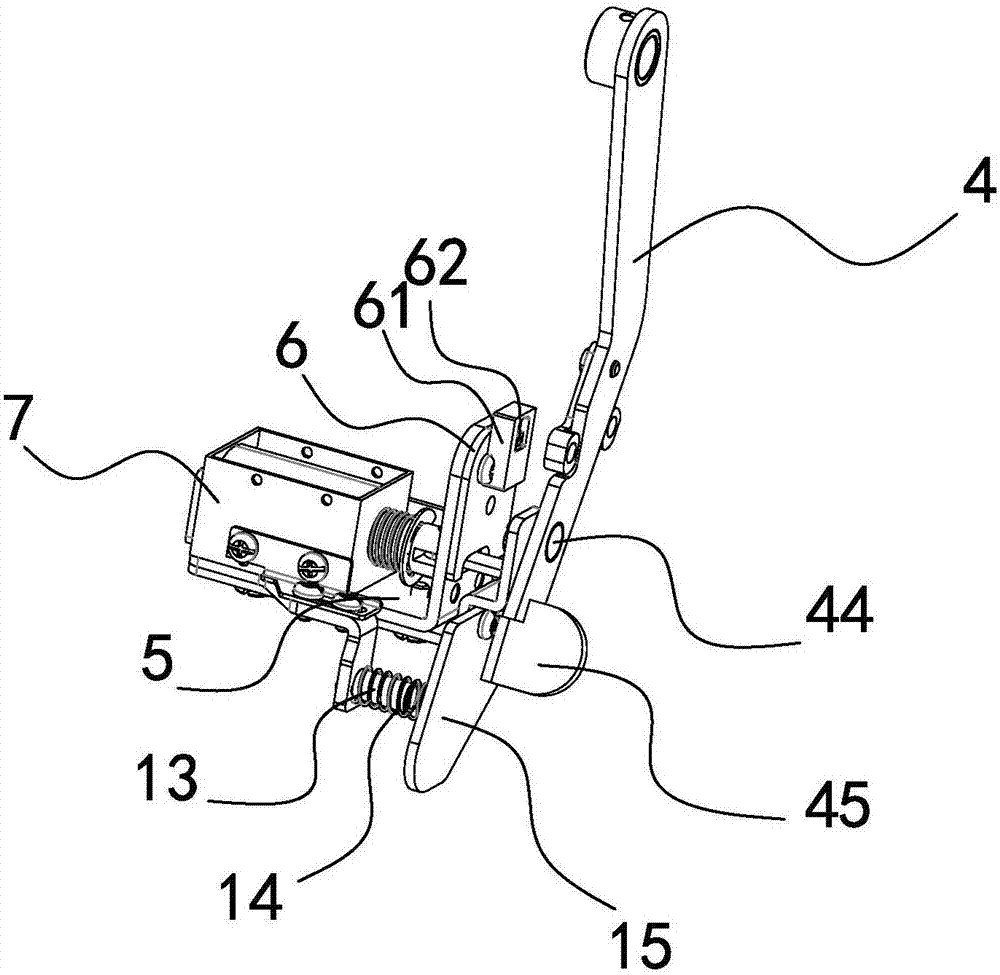

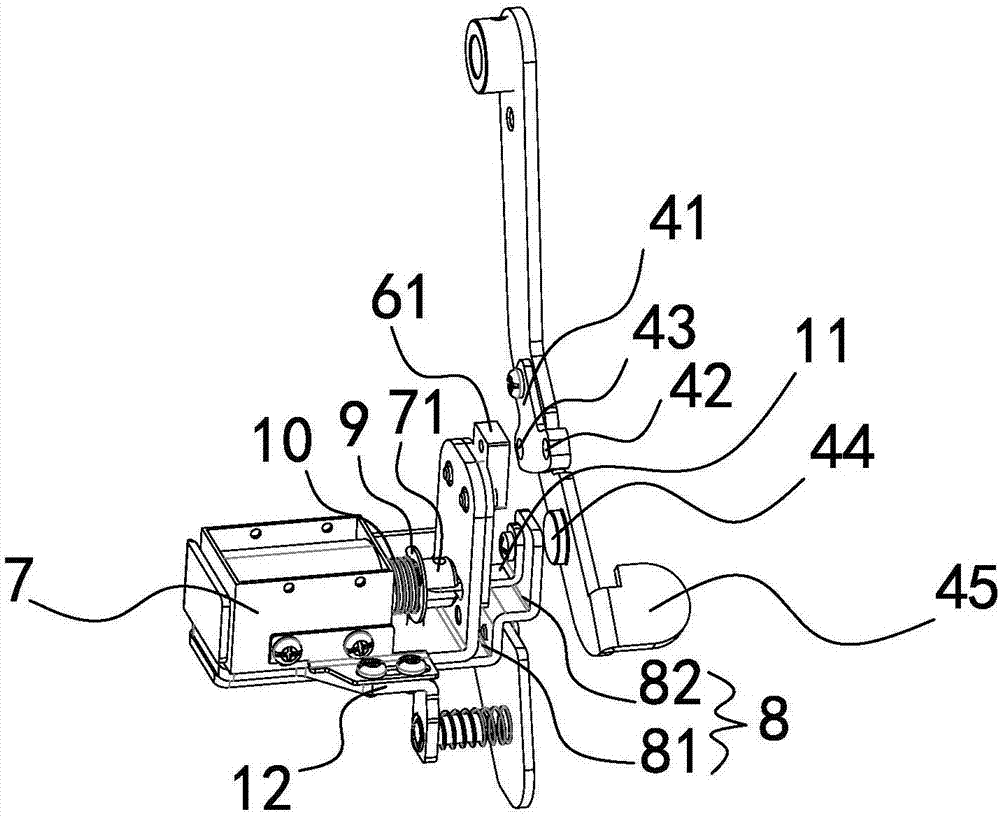

[0032] Such as figure 1 , 2 As shown in and 3, the needle bar clutch mechanism of this sewing machine is used on a double-needle machine, and includes a sliding shaft 1, one end of the sliding shaft 1 is connected with the separation assembly, and the other end is connected with the reset assembly 17. Certainly, it is conceivable that the sewing machine also includes structures such as the machine head 18, the body 19, the electric control of the sewing machine and the operation panel, and its structure and operation principle are known technologies in the art, and will not be described in detail. In the sewing machine electric control, the computer program can be compiled in advance to sew various types of corners (such ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com