Preparation method of wetting agent used for oil-based drilling fluid, and oil-based drilling fluid using the same

A technology of oil-based drilling fluid and wetting agent, which is applied in petroleum exploration and development, and in the field of oil-based drilling fluid. It can solve the problems that the drilling fluid is difficult to meet the requirements, and achieve the effect of meeting the requirements of on-site construction, low plastic viscosity and good rheology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

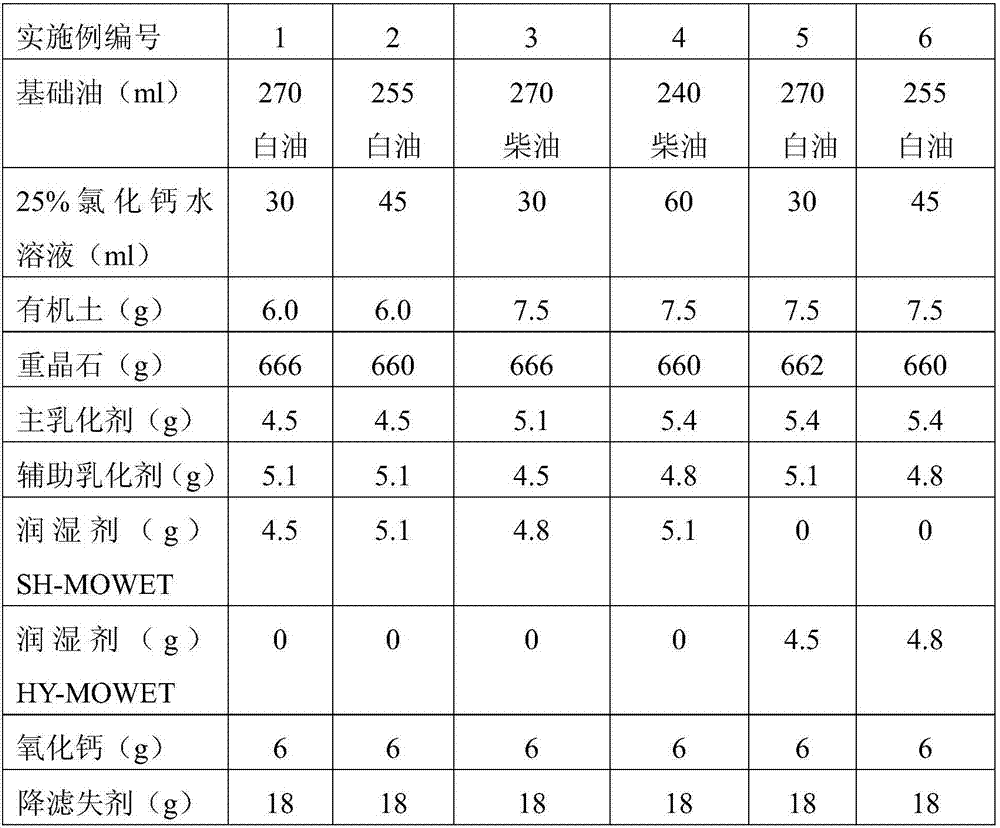

[0030] The preparation method of above-mentioned oil base drilling fluid is as follows:

[0031] (1) Measure the base oil (white oil or diesel oil) with a measuring cylinder, pour it into a high stirring cup, add the main emulsifier, auxiliary emulsifier and wetting agent, and stir at high speed for 5 minutes;

[0032] (2) Add 25% calcium chloride aqueous solution and stir for 15 minutes;

[0033] (3) Add calcium oxide, organic soil, and fluid loss control agent, and stir at high speed for 10 minutes;

[0034] (4) Add barite and stir at high speed for 30 minutes.

[0035] The high stirring refers to stirring at 12000 rev / min on a high-speed stirrer.

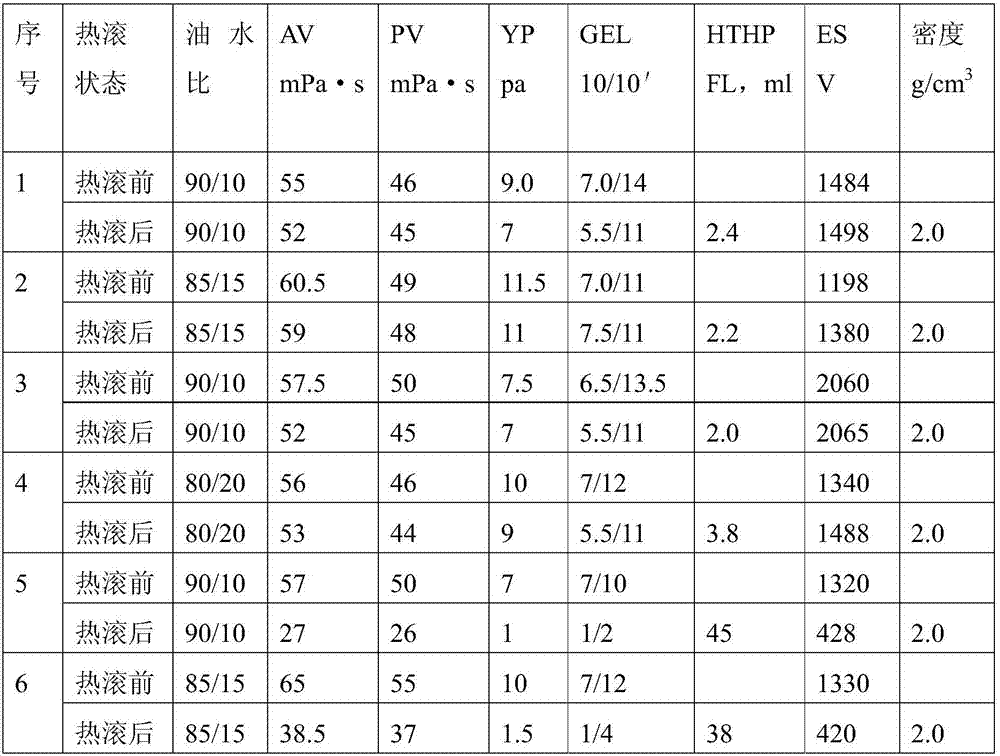

[0036] According to the following steps, the oil-based drilling fluids prepared in Examples 1-4 and Comparative Examples 5-6 were measured to obtain the following data:

[0037] (1) Pour the prepared oil-based drilling fluid into a measuring cup with a heating jacket, heat it to 66°C, and measure the rheology and demulsificati...

example 1

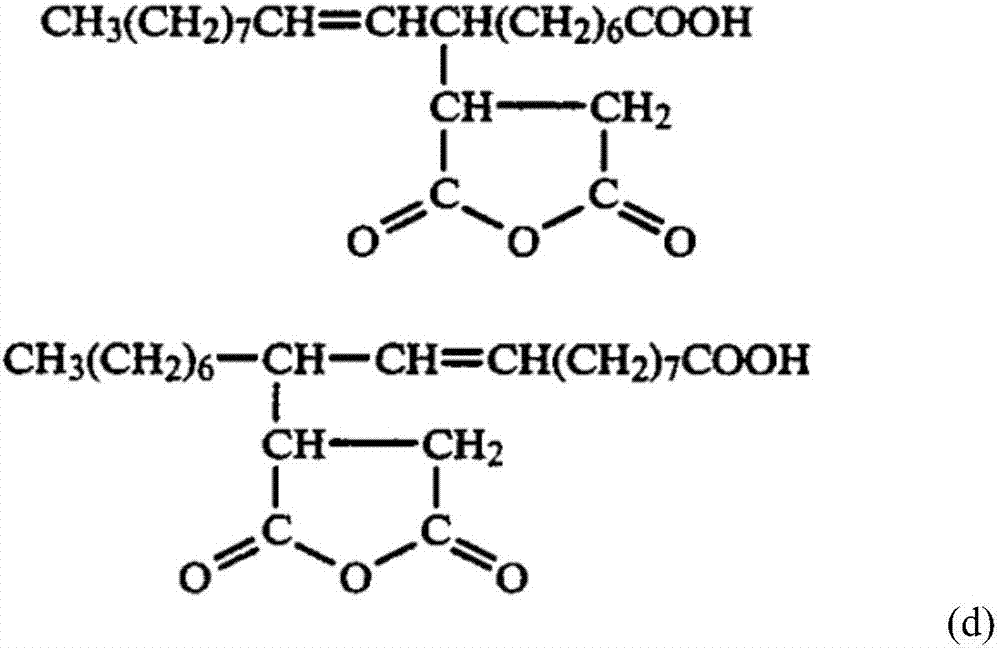

[0090] In a three-neck flask equipped with a thermometer, condenser and dehydration device, add 140g vegetable oil fatty acid, 25g maleic anhydride and a small amount of iodine, start stirring, heat the mixture to 200-220°C, react for 2-4 hours, and cool down to 130°C ℃, then add 50g of diethylenetriamine, after 160℃, the reactant starts to dehydrate, heat and dehydrate until no water comes out at 260℃, add 176g of vegetable oil fatty acid and heat to 220℃, divide the water until no more water comes out, then cool down To 130°C, add 100ml of xylene, stir evenly, and the reaction is complete.

example 2

[0092] In a three-necked flask equipped with a thermometer, a condenser and a dehydration device, add 140g of vegetable oil fatty acid, 20g of fumaric acid, and 0.3g of iodine, start stirring, heat the mixture to 200-220°C, react for 2-4 hours, and cool down to 130°C, then add 50g of diethylenetriamine, after 160°C, the reactant starts to dehydrate, heat and dehydrate until no water comes out at 260°C, add 176g vegetable oil fatty acid and heat to 220°C, react until no more water comes out. Cool down to 130°C, add 100ml of xylene, stir evenly, and the reaction is complete.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com