Correction shoe making method and system based on image recognition and three-dimensional modeling technique

A technology of 3D modeling and image recognition, which is applied to footwear, foot or shoe last measuring devices, clothing, etc., can solve the problems of no accurate plantar pressure testing process, short production cycle, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0196] The following methods are used to make orthopedic shoes: collect foot images and other health data to obtain source data; use the network to collect source data; The secondary data of the model; 3D modeling, that is, using the secondary data to perform 3D feature extraction and marking, coordinate conversion, point cloud splicing, and global optimization of the model to form a 3D model of the foot that is consistent or nearly consistent with the real foot shape; according to the patient According to the deformity of the foot or other health data, the 3D model of the foot is corrected to form a corrected 3D model that can contain at least one disease treatment plan; shoes are made according to the corrected 3D model, and the inner sole of the shoe is restored to the proportion of the real foot. The sole of the corrected 3D model fits perfectly (that is, the insole of the shoe corresponds to the shape of the sole of the corrected 3D model after restoration), and the minimu...

Embodiment 2

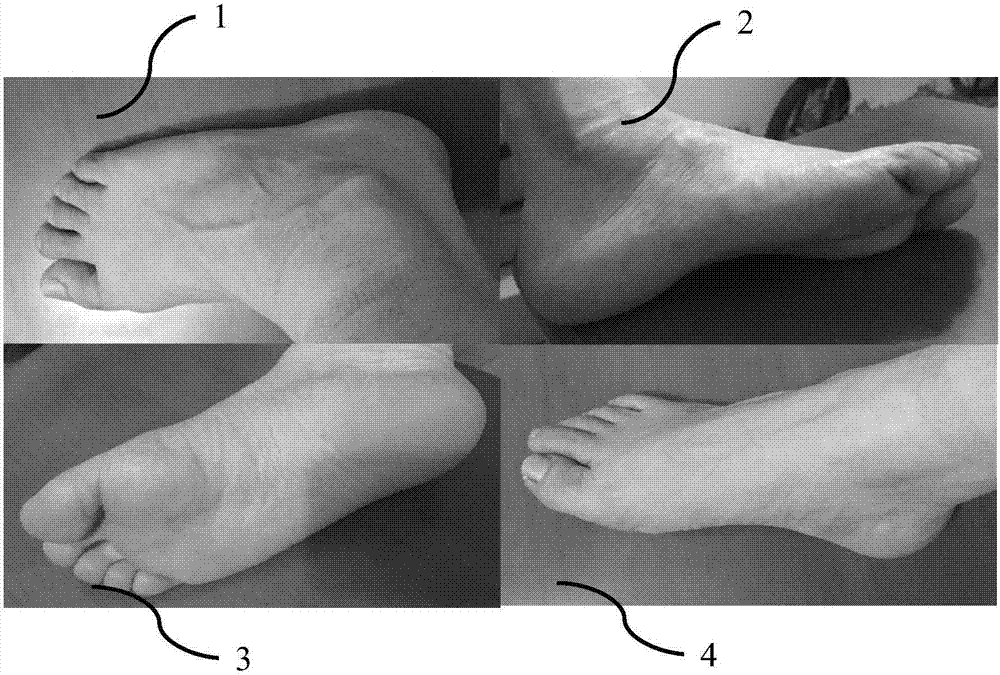

[0200]The orthopedic shoes are made by the following method: the patient takes 4 images of the feet with the camera function of the mobile phone, measures the foot length information, collects other health data at the same time, and obtains the source data; uses the network to collect the source data; uses the computer to restore the 4 images , enhancement, segmentation, and conversion into secondary data for 3D modeling; using secondary data for 3D feature extraction and marking, coordinate conversion, point cloud splicing, and global optimization of the model to form a foot that is consistent or nearly consistent with the real foot shape The three-dimensional model of the foot; according to the patient's foot distortion or other health data, the three-dimensional model of the foot is corrected to form a corrected three-dimensional model that can contain at least one disease treatment plan; the inner sole of the shoe is made and restored to the corrected three-dimensional model...

Embodiment 3

[0206] The orthopedic shoes are produced by the following method: the patient takes two images of the feet with the camera function of the mobile phone, measures and obtains the foot length information, and collects other health data at the same time to obtain the source data; uses the network to collect the source data; uses the computer to restore the two images , enhancement, segmentation, and conversion into secondary data for 3D modeling; using secondary data for 3D feature extraction and marking, coordinate conversion, point cloud splicing, and global optimization of the model to form a foot that is consistent or nearly consistent with the real foot shape The three-dimensional model of the foot; according to the patient's foot distortion or other health data, the three-dimensional model of the foot is corrected to form a corrected three-dimensional model that can contain at least one disease treatment plan; the inner sole of the shoe is made and restored to the corrected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com