Torquer pairing method for quartz flexibility accelerometer production

A technology of accelerometer and torquer, which is applied in the field of production technology, can solve the problems that the upper/lower torquer cannot be completely matched, it is difficult to find the minimum difference of magnetic induction intensity, and the matching process is labor-intensive and time-consuming, so as to achieve matching efficiency and The effect of high quality, convenient input and high matching success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] A torque device pairing method in the production of a quartz flexible accelerometer, comprising the steps of:

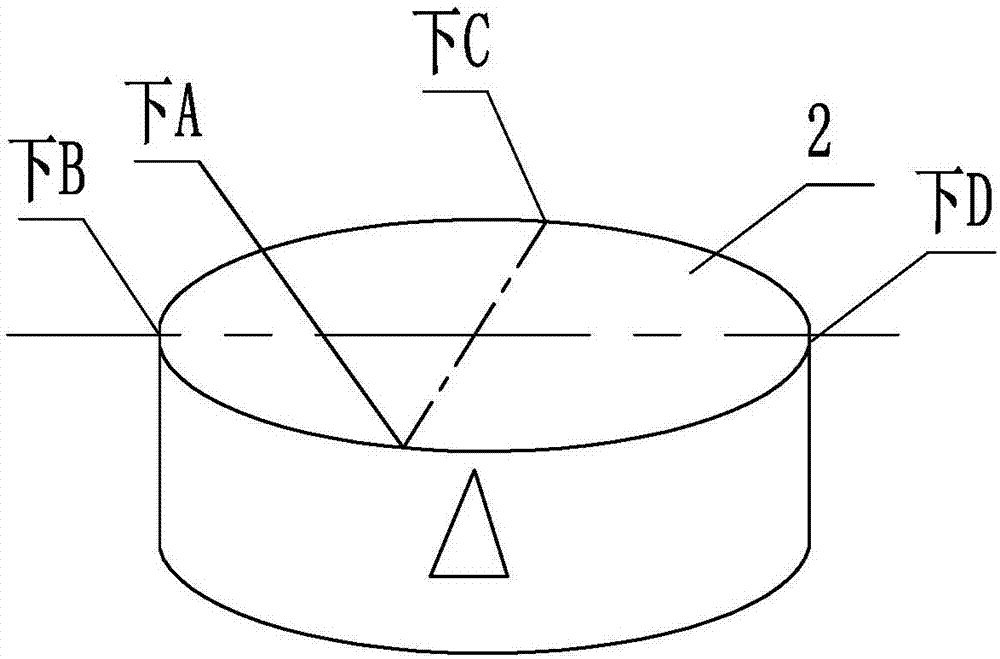

[0050] Step 1: Number the whole batch of N (such as 250) upper torque devices and N (such as 250) lower torque devices, and test their height, the parallelism dimension of the end faces of the upper torque device and the lower torque device respectively And the magnetic saturation value of 4 corresponding points;

[0051] The second step: input all the data measured in the first step into the computer:

[0052] S21: Input the numbers of N upper torque devices and N lower torque devices;

[0053] S22: Input the height and end parallelism dimensions of the upper torque device and the lower torque device with corresponding numbers;

[0054] S23: Input the magnetic saturation values of the 4 corresponding points of the upper torque device and the lower torque device with corresponding numbers;

[0055]Step 3: Calculate and record the difference between the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com