Plate thickness self-adaption adjustable RTM mold and plate preparation method

A self-adaptive, mold technology, applied in the field of composite product molding, can solve problems such as unreasonable position design of glue injection holes and vent holes, inability to produce composite material sheet products, affecting product quality, etc., to reduce product defects, The effect of shortening filling time and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

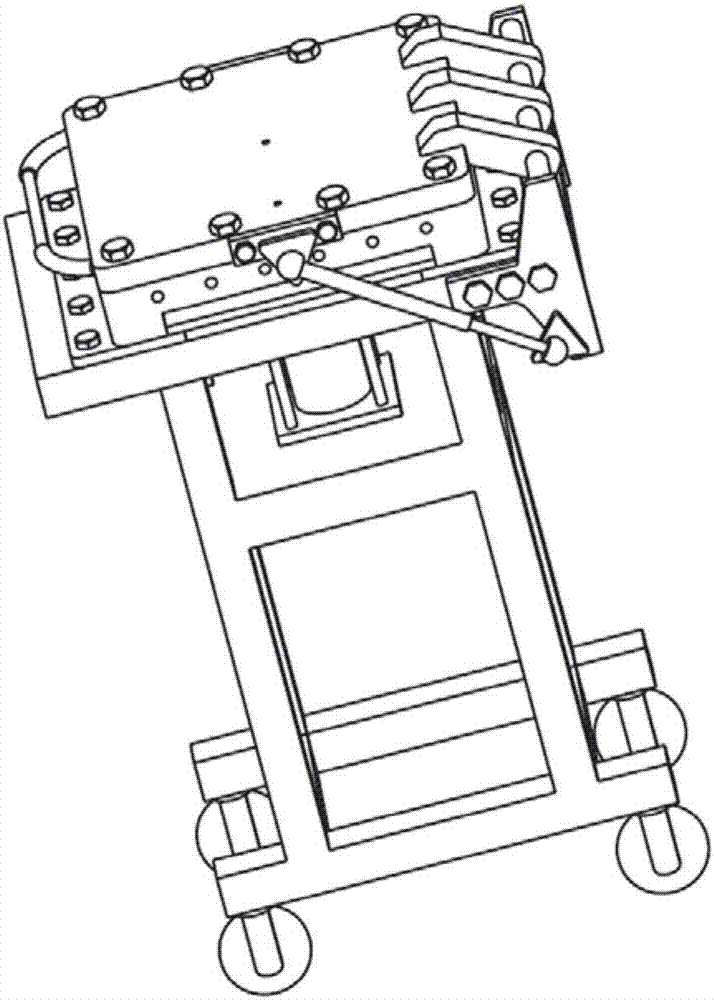

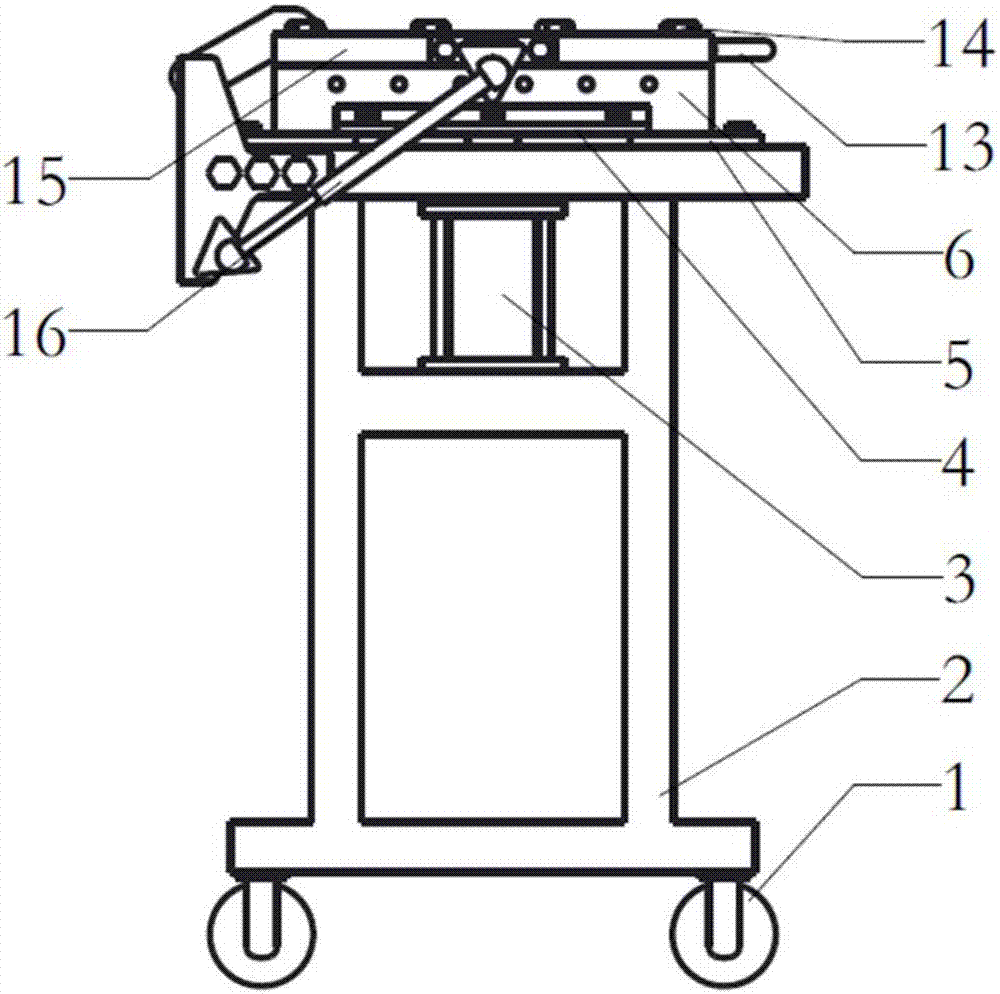

[0046] The present invention provides a self-adaptive and adjustable RTM die of sheet material thickness, and its structure is as follows Picture 1-1 , Figure 1-2 , diagram 2-1 , Figure 2-2 , image 3 with Figure 4 Shown, including:

[0047] Roller 1, frame 2, cylinder 3, ejector plate 4, carrying plate 5, lower template 6, screw 7, spring 8, push rod 9, PTFE sheet 10, main sealing ring 11, auxiliary sealing ring 12, Handle 13, fastening bolt 14, upper template 15, gas spring 16, heating channel 17, and flow channel 18.

[0048] Such as Picture 1-1 with Figure 1-2 As shown, the frame 2 is used to carry the weight of the entire RTM mold and to fix related parts of the RTM mold. In order to facilitate the movement, a roller 1 is provided at the bottom.

[0049] The upper template 15 is connected with the frame 2 by a gas spring 16 on one side, and is hingedly connected with the frame 2 on the other side. The upper template 15 is a flat plate, and a handle 13 is provided on one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com