Power-assisted shoe

A technology of power-assisted shoes, front and rear ends, applied in the field of power-assisted shoes, which can solve problems such as weak power-assisted, uncomfortable wearing, and laborious bending of the metatarsophalum and toes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

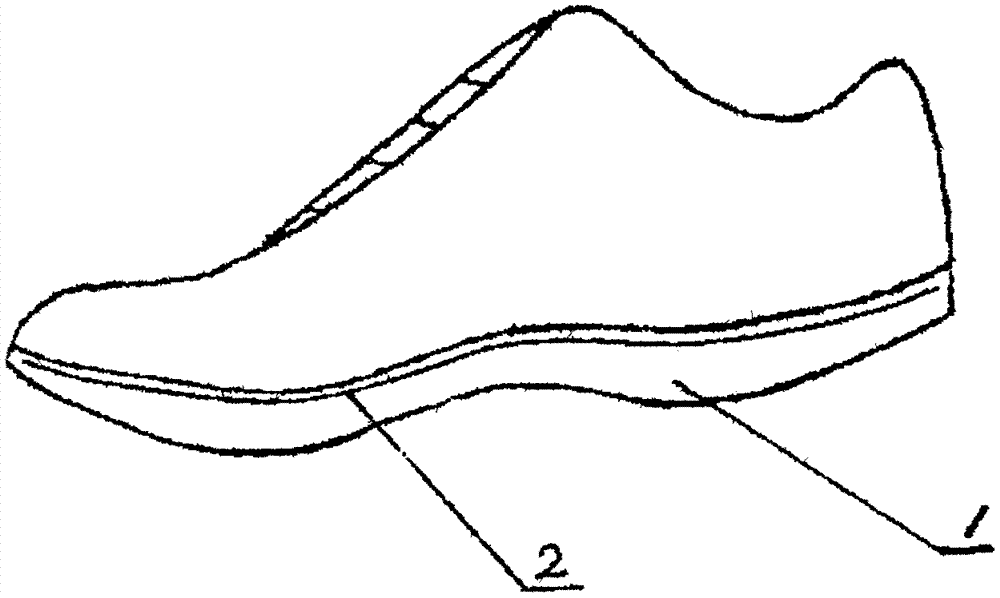

[0015] Such as figure 1 As shown, in the sole 1 whose front and rear ends are upturned, a tensile layer 2 capable of bending and straightening is provided. Materials with high tensile strength, low elongation at break, soft and bending resistance, such as fibers, cords, screens, etc., can be used as tensile members, and fixed in the soles by injection molding, bonding, pouring, etc. , forming a longitudinal tensile layer. Kevlar (Kevlar 1414), for example, is one of the available materials. The ideal effect can also be achieved by setting a thin plate with high tensile strength, low elongation at break, soft and bending resistance in the sole, or forming a tensile layer with similar properties in the sole by 3D printing and other methods. The tensile layer is usually placed on the upper layer of the sole; if the process method is special, the hardness of the sole material is too high, etc., the tensile layer can be placed on the middle layer of the sole, or even on the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com