Vehicle electronic whistling horn control circuit having temperature compensation and compensation method

A temperature compensation circuit and temperature compensation technology, applied in electrical components, sensors, frequency response correction, etc., can solve the problem that the car horn cannot obtain better environmental adaptability, and achieve the effect of good environmental adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

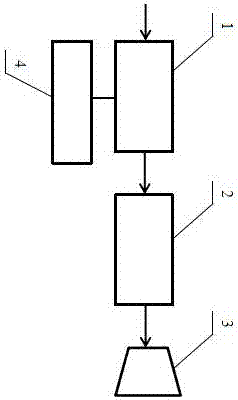

[0020] An electronic whistle horn control circuit with temperature compensation for a vehicle, comprising: a controller 1, a drive circuit 2, a horn system 3 and a temperature compensation circuit 4, the controller is connected to the drive circuit, the The drive circuit described above is connected to the speaker system, the controller and the temperature compensation circuit form a temperature compensation system, the controller sends corresponding pulses through the drive circuit, and the drive circuit The circuit drives the speaker system.

Embodiment 2

[0022] According to the compensation method of the electronic whistle horn control circuit with temperature compensation for the vehicle described in embodiment 1, the method comprises the following steps:

[0023] (1) The controller and the temperature supplementary circuit form a temperature compensation system, and the temperature compensation system completes the car electric horn and is more able to adapt to the environment when the temperature changes.

[0024] (2) The controller interacts with the temperature compensation circuit to obtain the signal obtained by the temperature compensation circuit;

[0025] (3) The controller sends corresponding pulses through the drive circuit;

[0026] (4) The drive circuit drives the horn system to work to generate chirping sound.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com