Light-gauge steel section and foam concrete interface sliding performance testing method

A technology of foam concrete and thin-walled steel, which is applied in the field of construction engineering to achieve the effects of high measurement accuracy, overcoming the difficulty of measurement, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] A specific embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiment.

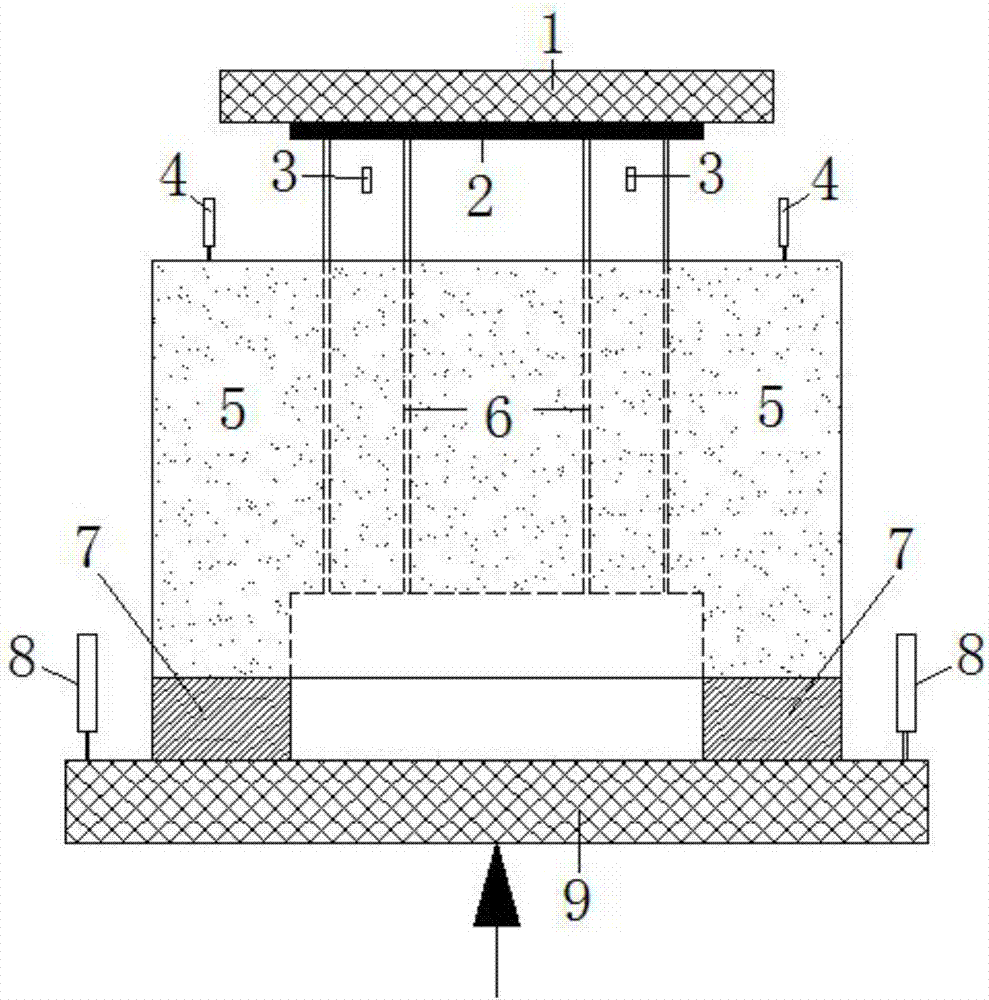

[0031] refer to image 3 and Figure 4 , the present invention provides a kind of thin-walled steel and foam concrete interface sliding performance test method, comprising the following steps:

[0032] 1) Preparation of test piece: According to the plane and elevation size requirements of the test piece, make a combined test piece of thin-walled steel and foam concrete, and reserve a 50mm long thin-walled steel at the upper end of the test piece; perform maintenance according to the conventional concrete component maintenance method Days;

[0033] 2) Test preparation: Paste strain gauges on the 50mm long thin-walled steel web reserved at the upper end of the specimen for strain measurement of this section of thin-walled ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com