A rotary liquid supply device

A technology of liquid supply and rotating shaft, applied in the field of rotating liquid supply, can solve the problems of the overall structure of the centrifuge is not compact, the axial dimension is long, etc., and achieve the effects of low pressure, small length, and easy processing accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

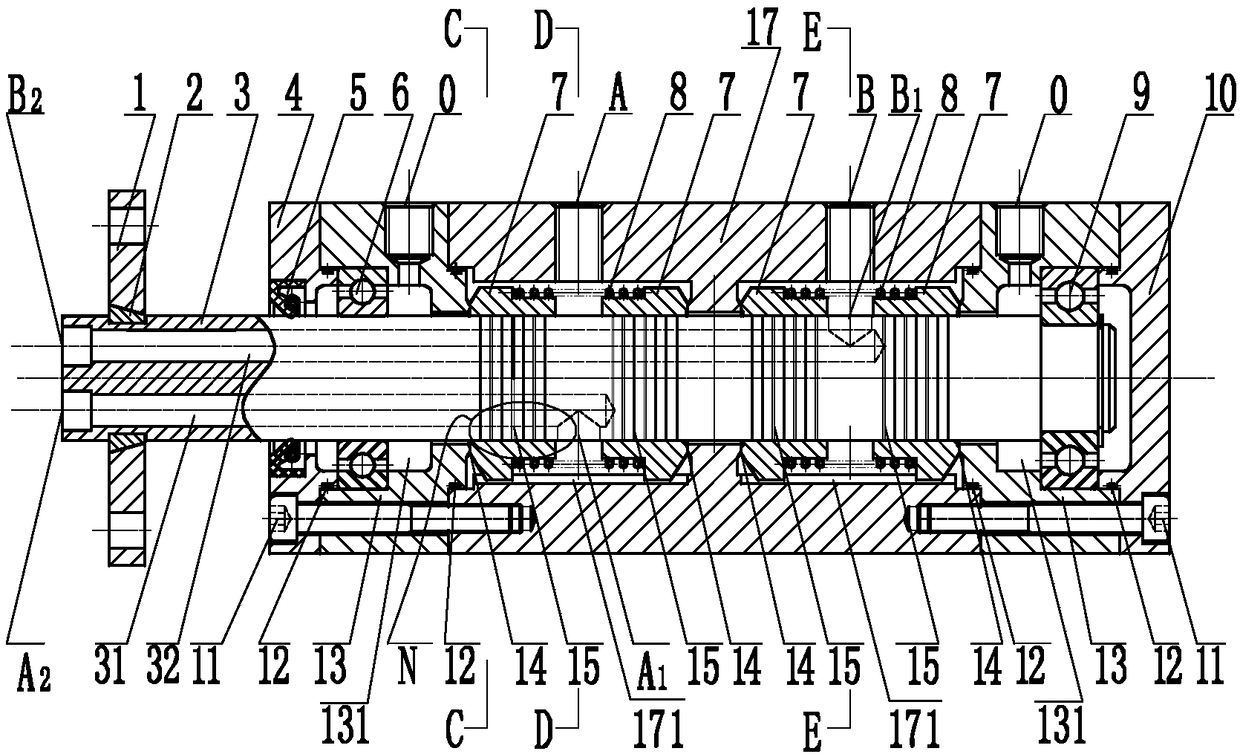

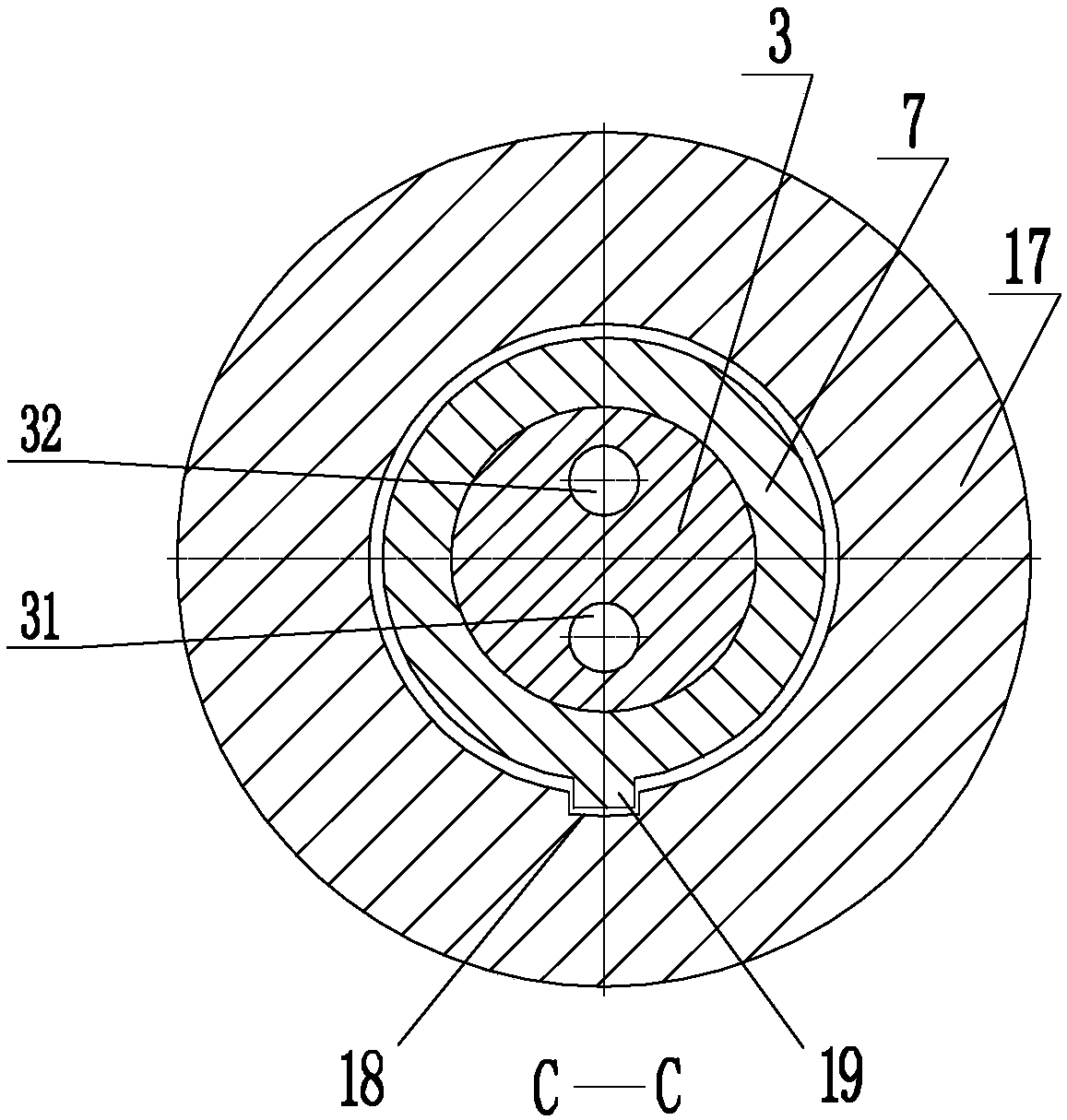

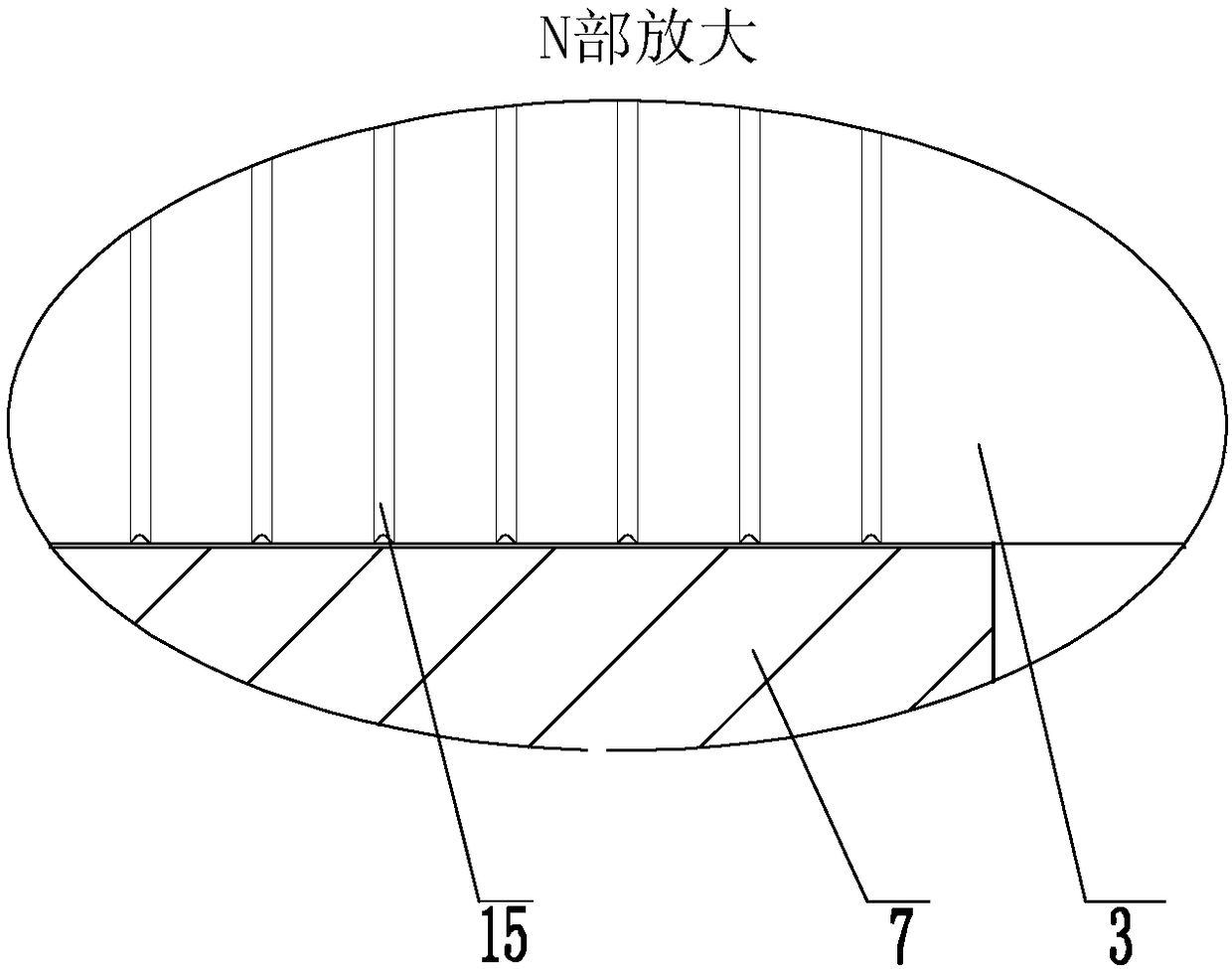

[0029] The present invention will be further described below with specific embodiments in conjunction with the drawings, see figure 1 — Figure 7 :

[0030] A rotary liquid supply device. The two ends of a hollow cylinder 17 are respectively connected with ring-shaped bearings 6, 9 seats 13. The inner walls of the bearings 6, 9 seats 13 are installed with bearings 6, 9 and the rotating shaft 3 is supported for rotation. On the inner rings of the bearings 6, 9, each bearing seat 13 and the outer ends of the bearings 6, 9 are provided with a sealing end cover 4, 10, and the rotating shaft 3 is provided with two axial liquid guide holes 31, 32 side by side. , Each liquid guide hole 31, 32 is provided with a radial liquid flow opening A1, B1 communicating with the liquid guide hole 31, 32, the cylinder 17 is provided with two annular grooves 171 at intervals, and each annular groove 171 Both are fitted with two floating sleeves 7 that are rotationally sealed with the rotating shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com