A kind of natural color bamboo raw pulp nonwoven fabric and preparation method thereof

A technology of non-woven fabrics and woven fabrics, applied in the field of natural-color bamboo pulp non-woven fabrics and its preparation, can solve the problems of unsatisfactory non-woven fabrics, poor strength of non-woven fabrics, and hard-feeling of non-woven fabrics, and achieve protection length and Morphological structure, reducing loosening, highlighting the effect of function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

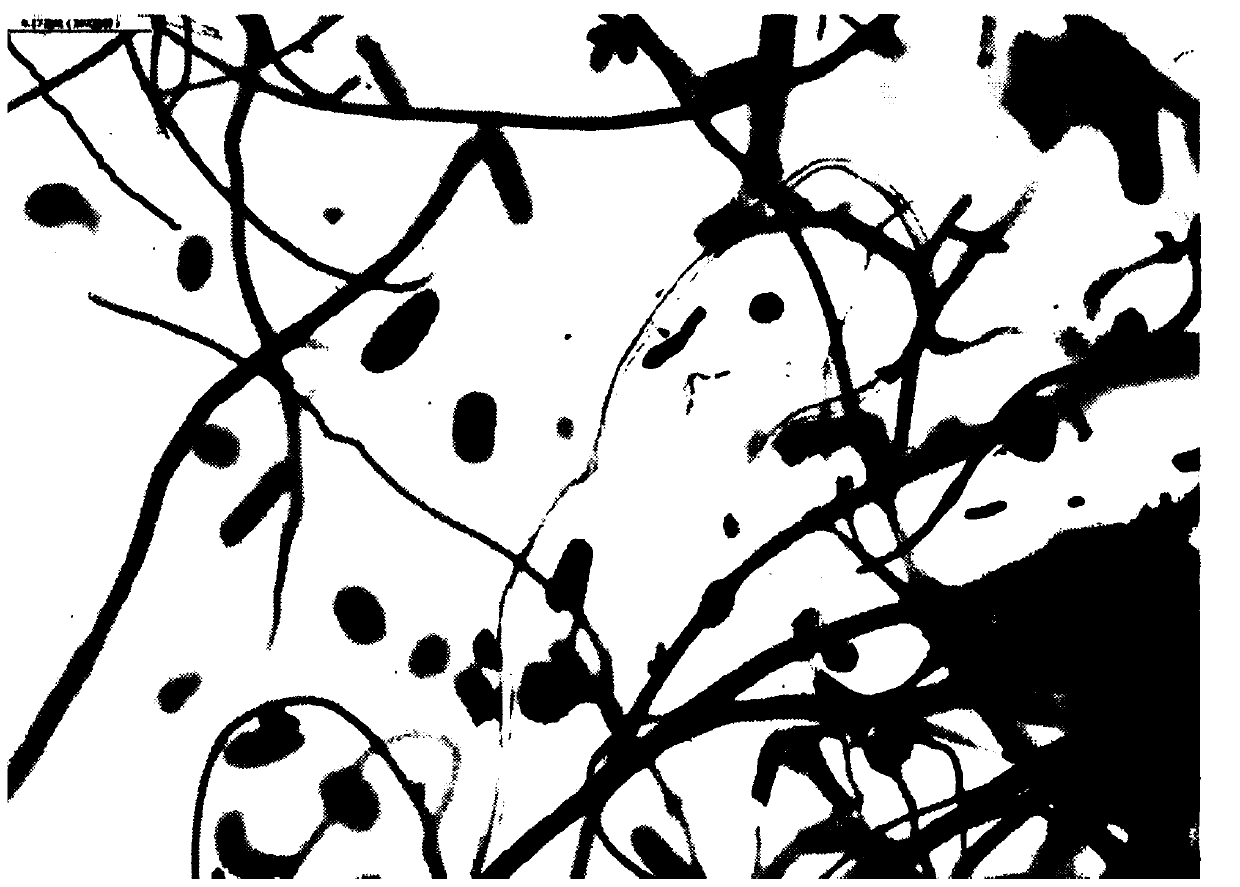

Image

Examples

Embodiment 1

[0042] Embodiment 1: a kind of preparation method of natural color bamboo pulp

[0043] Include the following steps:

[0044] 1. Raw material preparation: Slicing any one of bamboo such as Moso bamboo, Phyllostachys edulis, Cizhu, etc. into 20-60mm long, 10-30mm wide, and washed with water to obtain washed bamboo slices;

[0045] 2. Cooking: Put the washed bamboo slices into a cooking pot at 150°C for 80-180 minutes to get the slurry;

[0046] 3. Washing: washing the slurry obtained in step 2 with washing equipment and water to obtain the cleaned slurry;

[0047] 4. Slag removal: pump the cleaned slurry to the slag removal system for slag removal;

[0048] 5. Beating: transport the washed and purified slurry to the beating equipment to make bamboo pulp; the beating degree is greater than 55゜SR.

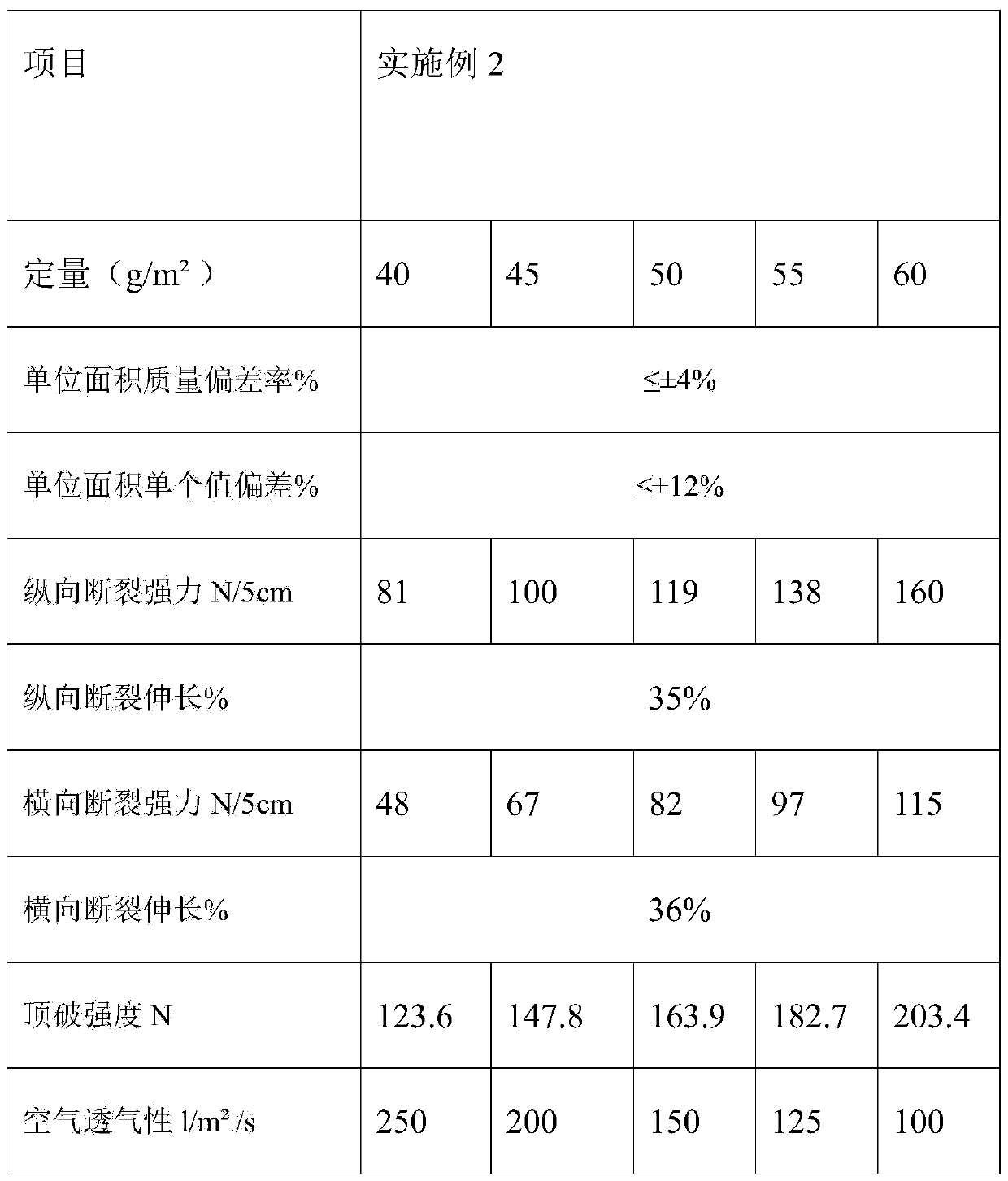

Embodiment 2

[0049] Embodiment 2: a kind of natural color bamboo raw pulp nonwoven fabric

[0050] A non-woven fabric of natural-color bamboo pulp, which is composed of 1-99% by weight of the natural-color bamboo pulp obtained in Example 1, 1-99% by weight of other short fibers for textile use, natural-color bamboo pulp and other textile Use short fibers to bond, bond or compound together to form a three-dimensional net-like weaving structure; the natural bamboo pulp is made of bamboo as raw material through a special pulping process, and does not contain harmful substances and any chemical additives 100% plant natural natural color paste; the other short textile fibers are selected from at least one of natural fibers, chemical fibers and artificial fibers.

[0051] The preparation method of described natural color bamboo pulp nonwoven fabric is as follows:

[0052] 1. Mixing: 1-99% by weight of the original bamboo pulp obtained in Example 1 is mixed with 1-99% by weight of other textile ...

Embodiment 3

[0057] Embodiment 3: a kind of natural color bamboo raw pulp nonwoven fabric

[0058] A natural-color bamboo pulp non-woven fabric, the natural-color bamboo pulp non-woven fabric is composed of 1-99% by weight of the natural-color bamboo pulp obtained in Example 1, 1-99% by weight of other textile staple fibers, and includes Woven or non-woven fabric, the preparation method of the natural color bamboo pulp non-woven fabric is as follows:

[0059] 1, blending: the raw bamboo pulp obtained in Example 1 is blended with other short fibers for textiles to obtain semi-finished bamboo pulp paper;

[0060] 2. Composite: According to different product characteristics and requirements, the semi-finished bamboo pulp paper obtained in step 1 is composited with existing various types of woven or non-woven fabrics;

[0061] 3. Reinforcement: use existing nonwoven fabric technologies such as mechanical consolidation, thermal bonding, self-bonding, etc. for reinforcement;

[0062] 4. Drying...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com