Preparation method of few-layer MoS2 thin film

A thin film and equipment technology, which is applied in the field of preparation of few-layer MoS2 thin films, can solve the problems of reducing the electrical properties of MoS2, and achieve the effect of increasing the area, reducing requirements, and increasing the area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

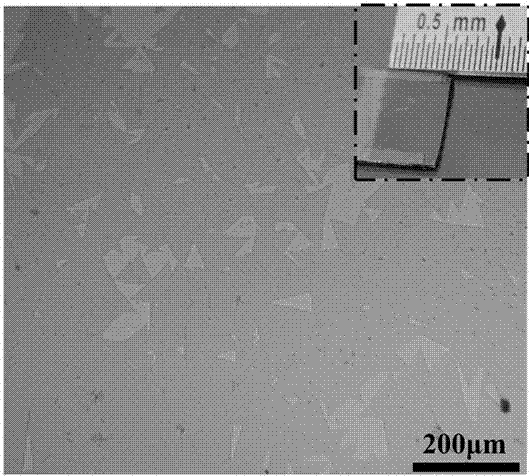

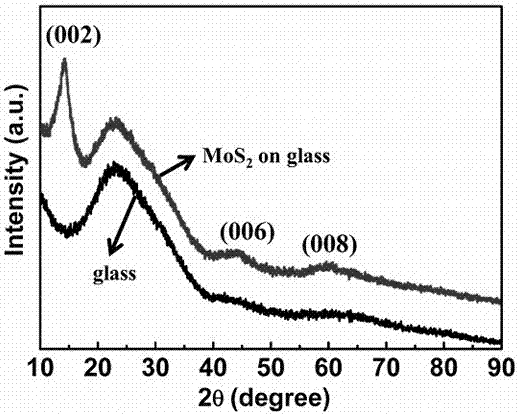

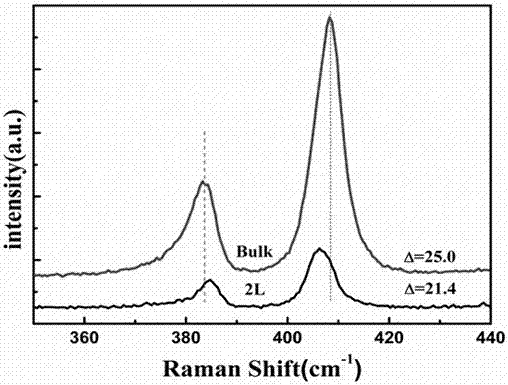

[0022] A few-layer MoS 2 thin film preparation method to MoO 3 Powder and S powder are the precursors, and the dual-temperature zone tube furnace is the equipment. The specific steps are as follows:

[0023] (1) MoO 3 Thin film deposition: 0.1 g MoO 3 The powder (99.9%) is placed at one end of a quartz boat with a diameter of 1.5 cm and a length of about 15 cm, which will be sequentially cleaned by acetone, absolute ethanol, deionized water, and O 2 The plasma-treated 2cm×2cm Si wafer is placed upside down on the other end of the quartz boat, and the inert gas N 2 , an inert gas from MoO 3 One end of the powder flows to the other end of the substrate, for MoO 3Heating, the heating temperature is 750°C, the heating rate is 15°C / min, the holding time is 5min, the pressure is 100Pa, the flow rate of the inert gas is 100sccm, and MoO is obtained on the substrate 3 film;

[0024] (2) MoO prepared in step (1) 3 The film and 1g of S powder were placed in the two temperature z...

Embodiment 2

[0030] A few-layer MoS 2 thin film preparation method to MoO 3 Powder and S powder are the precursors, and the dual-temperature zone tube furnace is the equipment. The specific steps are as follows:

[0031] (1) MoO 3 Thin film deposition: 0.1 g MoO 3 The powder (99.9%) is placed at one end of a quartz boat with a diameter of 1.5 cm and a length of about 15 cm, which will be sequentially cleaned by acetone, absolute ethanol, deionized water, and O 2 Plasma-treated 2cm x 2cm SiO 2 / Si sheet is placed upside down on the other end of the quartz boat, and the inert gas N is introduced 2 , an inert gas from MoO 3 One end of the powder flows to the other end of the substrate, for MoO 3 Heating, the heating temperature is 650°C, the heating rate is 13°C / min, the holding time is 30min, the pressure is normal pressure, the flow rate of the inert gas is 20 sccm, and MoO is obtained on the substrate 3 film;

[0032] (2) MoO prepared in step (1) 3 The thin film and 1.3g S powder ...

Embodiment 3

[0034] A few-layer MoS 2 thin film preparation method to MoO 3 Powder and S powder are the precursors, and the dual-temperature zone tube furnace is the equipment. The specific steps are as follows:

[0035] (1) MoO 3 Thin film deposition: 0.1 g MoO 3 The powder (99.9%) is placed at one end of a quartz boat with a diameter of 1.5 cm and a length of about 15 cm, which will be sequentially cleaned by acetone, absolute ethanol, deionized water, and O 2 The plasma-treated sapphire substrate is placed upside down on the other end of the quartz boat, and the inert gas N 2 , an inert gas from MoO 3 One end of the powder flows to the other end of the substrate, for MoO 3 Heating, the heating temperature is 850°C, the heating rate is 10°C / min, the holding time is 2min, the pressure is 30Pa, the flow rate of the inert gas is 300 sccm, and MoO is obtained on the substrate 3 film;

[0036] (2) MoO prepared in step (1) 3 The thin film and 1.5 g S powder were placed in the two tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com