Horizontal and vertical integrated transportation hoisting device for large-scale electromechanical equipment

A large-scale equipment and hoisting device technology, which is applied in the direction of hoisting equipment braking devices, transportation and packaging, hoisting devices, etc., can solve problems such as inability to use cranes and cranes cannot reach, and achieve strong practicability, simple operation, and efficient hoisting and safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Accompanying drawing further describes the present invention.

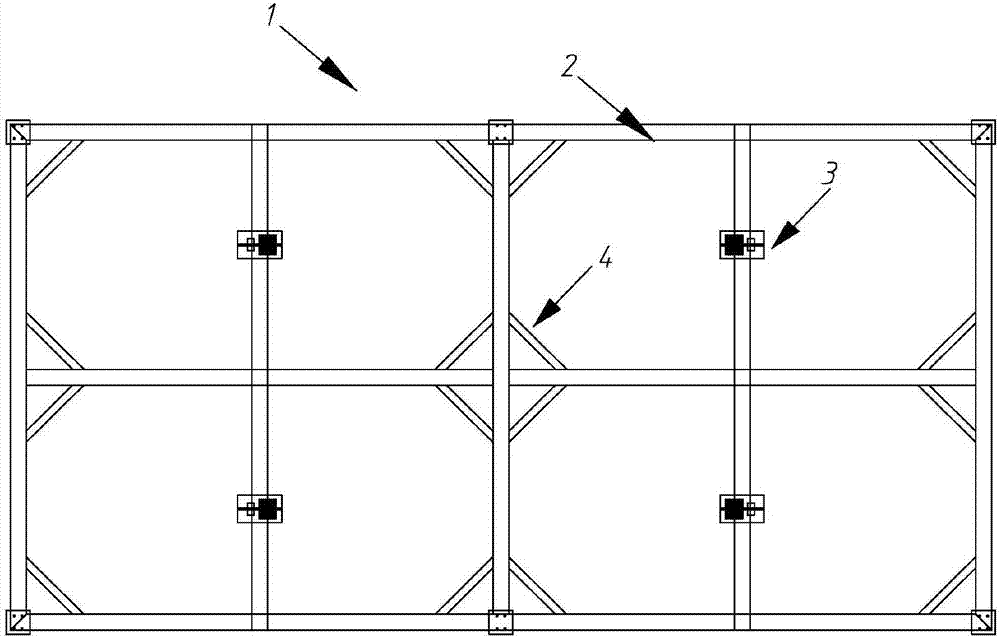

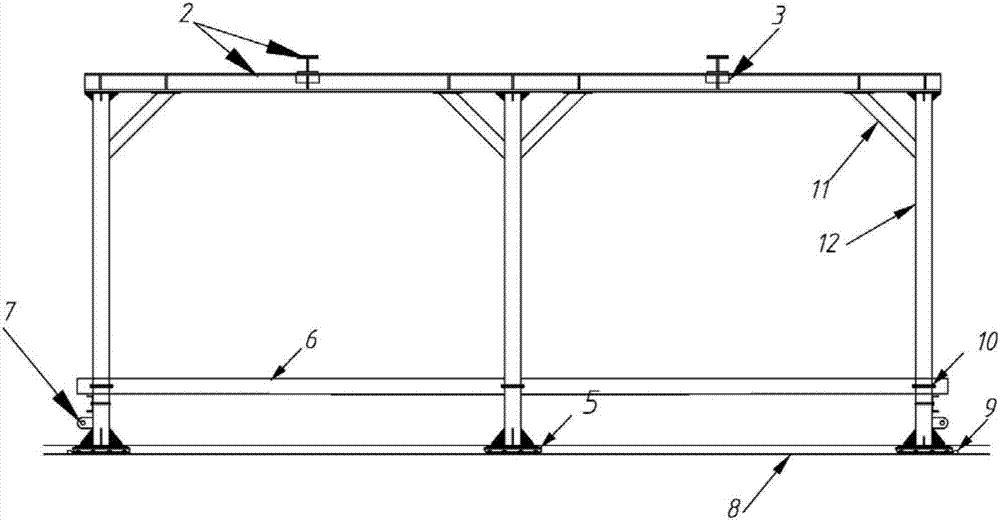

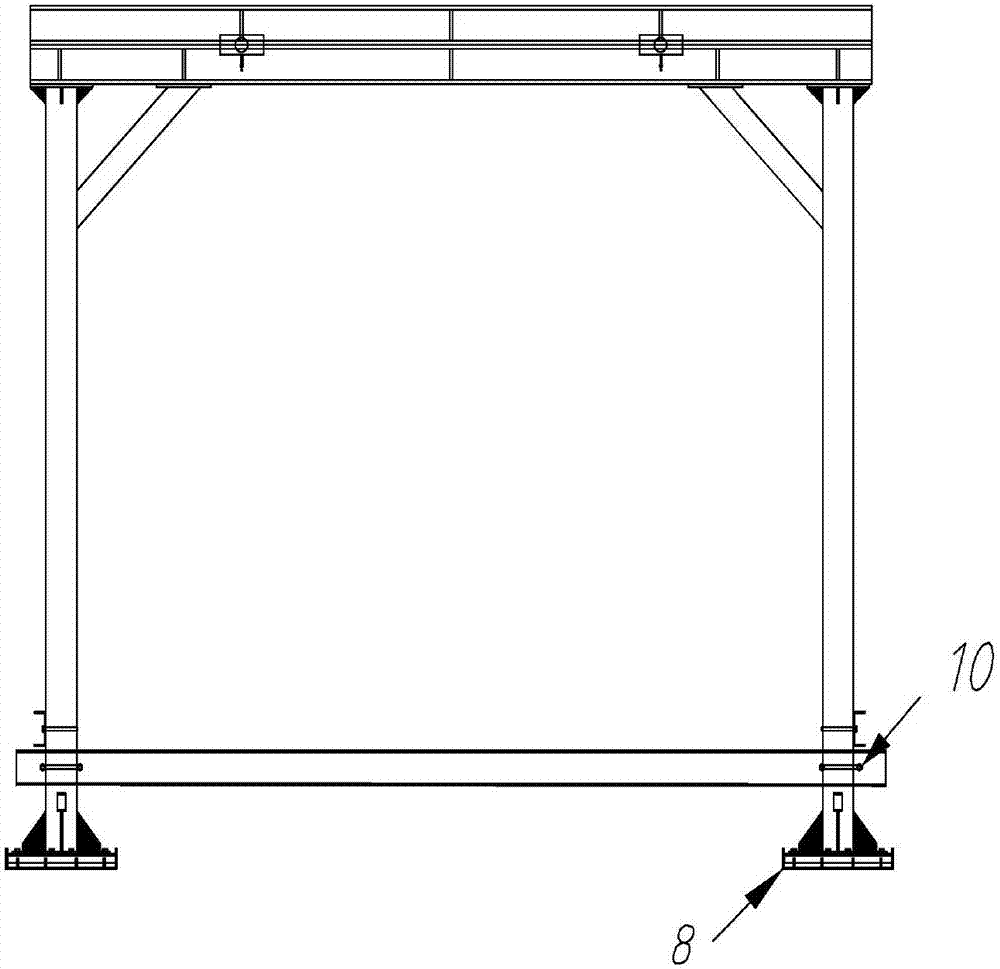

[0022] Such as figure 1 , figure 2 , image 3 As shown, the present invention includes a steel structure frame body 1, six ground tanks 5, four electric hoists 3, two guide rails 8, four hooks with holes 7, and four locking iron shoes 9, and is characterized in that the steel structure The frame body is composed of a steel structure frame 1 and a column 12. The steel structure frame 1 is welded with I-beams 2, and four electric hoists 3 are respectively installed on the two I-beams 2 in the steel structure frame; each side of the steel structure frame A column 12 is respectively fixed at both ends and the middle of the lower part of the long side, and a hook with a hole 7 is respectively welded to the bottom of the four columns 12 on both sides of the short side of the steel structure frame, and a detachable ground tank 5 is installed at the bottom of each column 12 , two guide rails 8 are fixed on the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com