Automatic packaging device and method for polycrystalline silicon rod

A technology for automatic packaging and polysilicon rods, which is applied in the directions of packaging, transportation and packaging, and the type of packaged items. It can solve the problems of secondary pollution, low efficiency, and long time consumption of polysilicon rods, and reduce packaging costs. The effect of secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

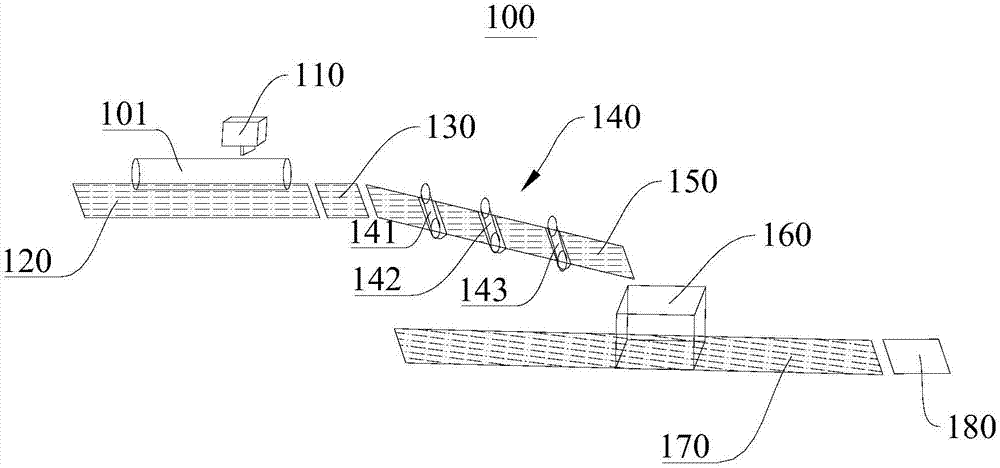

[0024] figure 1 A schematic structural diagram of an automatic packaging device 100 for polycrystalline silicon rods provided in this embodiment. see figure 1 In this embodiment, the automatic packaging device 100 for polycrystalline silicon rods includes a cutting device 110, a first conveyor belt 120, a rotating device 130, a packaging tank 140, an inclined plate 150, a packaging box 160, a second conveyor belt 170, and a controller 190 ( figure 1 not shown) and sealing device 180.

[0025] read on figure 1 , in this embodiment, the first conveyor belt 120 is used to transport the polycrystalline silicon rod 101, and the polycrystalline silicon rod 101 is cylindrical. The axial directions of the polycrystalline silicon rods 101 are consistent, which facilitates the transportation and cutting of the polycrystalline silicon rods 101 .

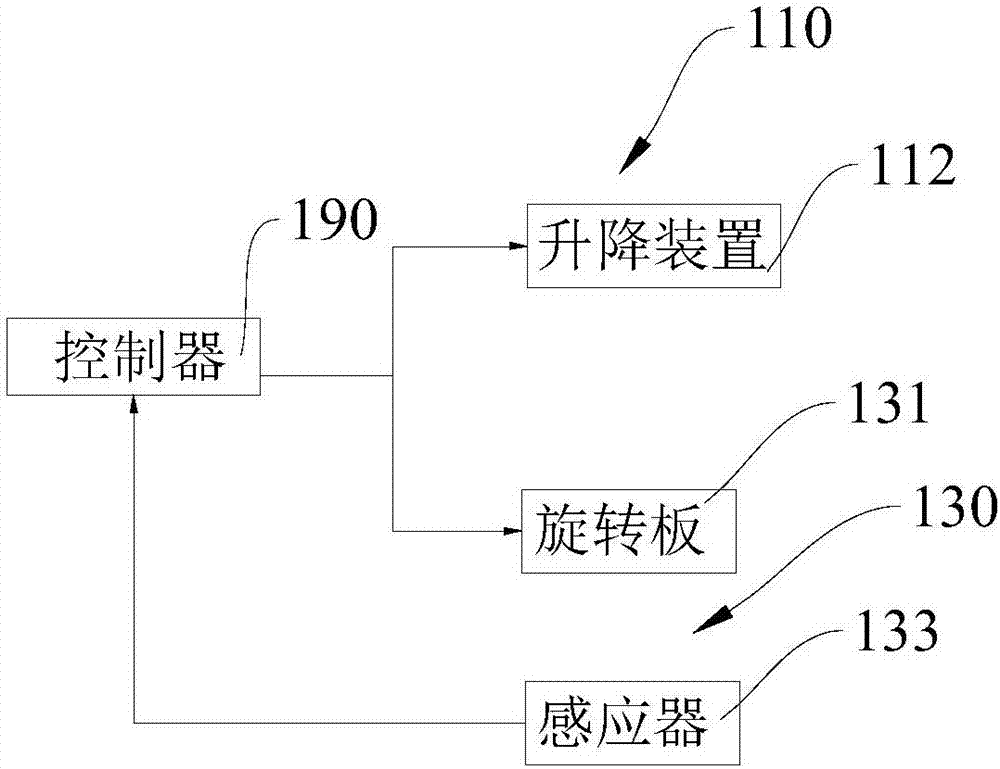

[0026] figure 2 A functional block diagram of the automatic packaging device 100 for polycrystalline silicon rods provided in this embod...

Embodiment 2

[0040] This embodiment provides an automatic packaging method for polycrystalline silicon rods, using the automatic packaging device 100 for polycrystalline silicon rods provided in Example 1 for packaging, including the following steps:

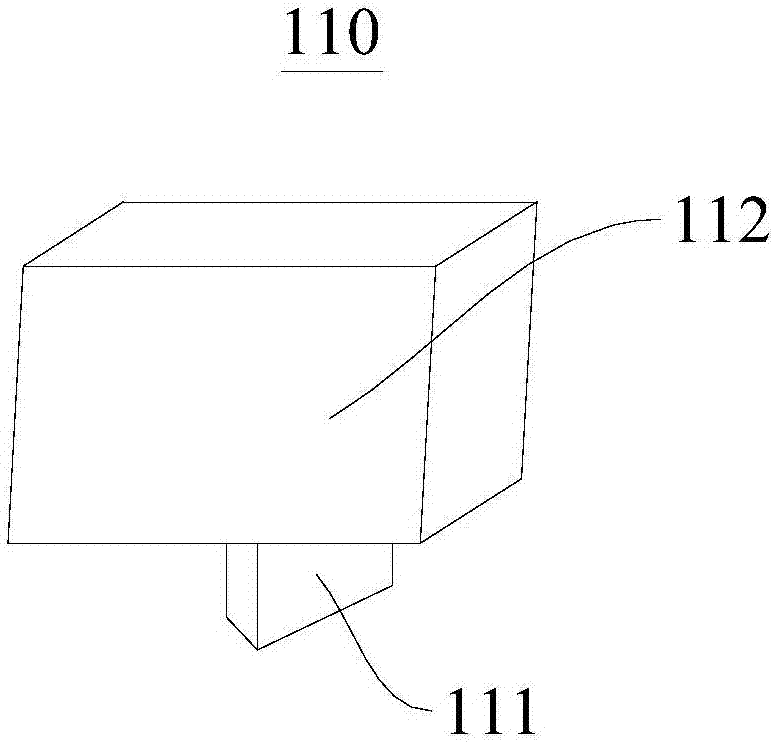

[0041] Place the polycrystalline silicon rod 101 on the first conveyor belt 120, and use the cutting device 110 to cut the polycrystalline silicon rod 101 into small sections during the transmission process. When the polycrystalline silicon rod 101 on the first conveyor belt 120 is transported to the bottom of the cutting device 110, The polycrystalline silicon rod 101 is cut using the cutter 111 of the cutting device 110 to reduce the length of the polycrystalline silicon rod 101 . Preferable setting: the length of polycrystalline silicon rod 101 after slitting is 150-450cm, to avoid polycrystalline silicon rod 101 being too long, causing troubles for transportation and packaging, and avoiding polycrystalline silicon rod 101 being too short,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com