An electromagnetic treatment device and working method for semi-continuous casting liquid cavity melt

A processing device and semi-continuous technology, which is applied in the field of metal material preparation, can solve the problems such as the inability to fully meet the requirements of grain size and composition uniformity, and achieve the effects of facilitating the arrangement of the crystallizer, improving the strength and taking up less space.

Active Publication Date: 2018-12-28

NORTHEASTERN UNIV LIAONING

View PDF10 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] In order to solve the above-mentioned problems existing in the prior art, the present invention is to design a semi-continuous casting liquid cavity melt electromagnetic treatment device and a device that is simple in structure, small in size, easy to realize industrial application, and does not need to apply a large current to the load coil. Its working method is to solve the problem that the light alloy semi-continuous casting billet cannot fully meet the requirements of the plastic deformation process (especially the forging process and rolling process) on the grain size and composition uniformity of the casting billet

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0079] Table 1: Results of regulation in the lower frequency range at low duty cycles.

[0080]

[0081]

Embodiment 2

[0083] Table 2: Results of regulation in the mid-frequency range at low duty cycles.

[0084]

Embodiment 3

[0086] Table 3: Results of regulation in the higher frequency range at low duty cycles.

[0087]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| breakdown voltage | aaaaa | aaaaa |

| capacitance | aaaaa | aaaaa |

Login to View More

Abstract

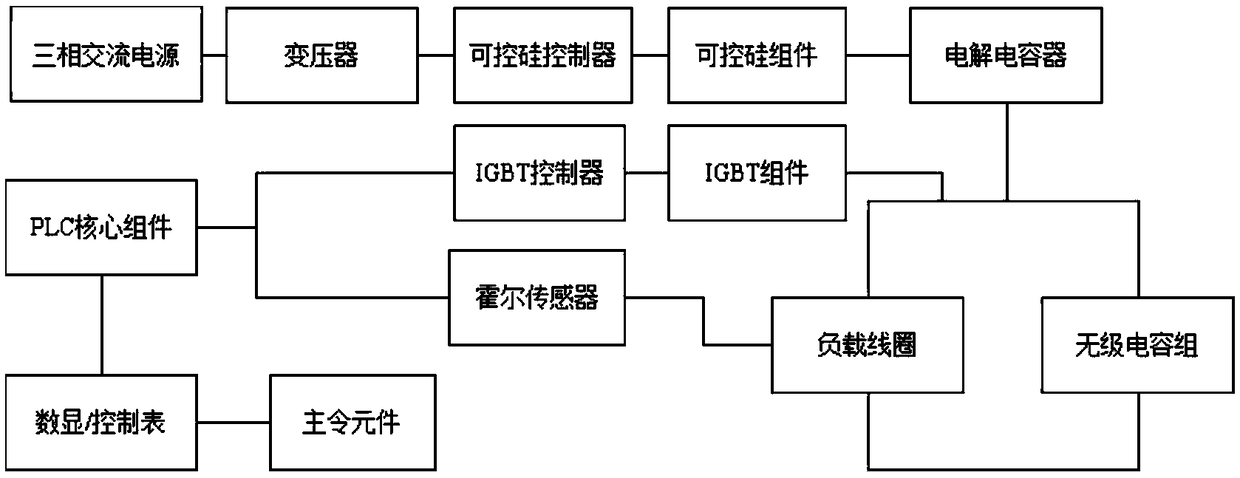

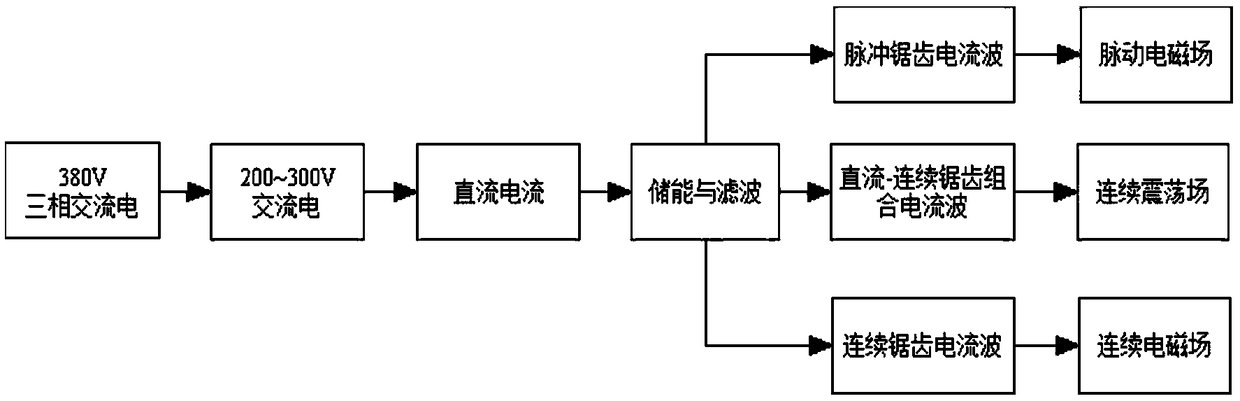

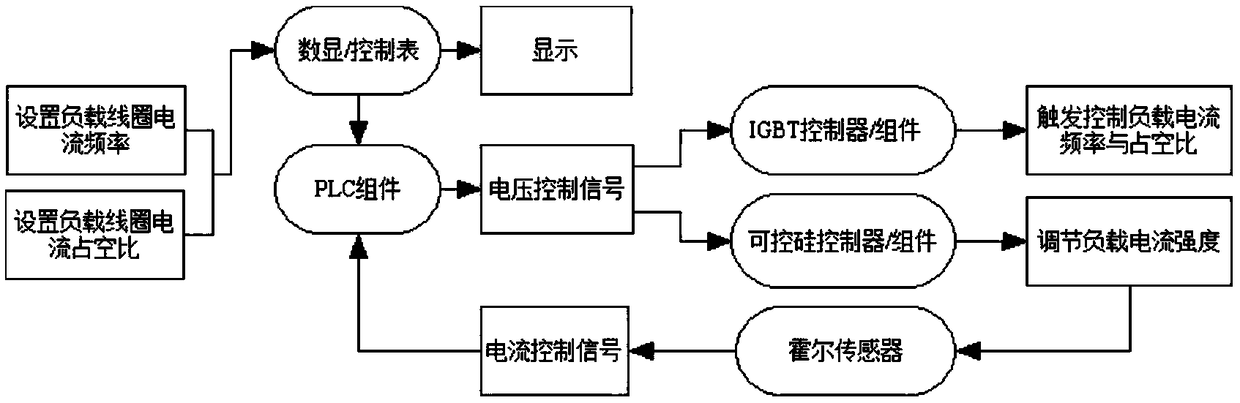

The invention discloses a semicontinuous casting liquid cave melt electromagnetic treatment device and a working method thereof. The electromagnetic treatment device comprises a silicon controllable controller, a silicon controllable assembly, an electrolytic capacitor set, an IGBT controller, an IGBT assembly, a hall sensor, a load coil, a PLC core component and a touch screen master element. The load coil is arranged in a cooling water cavity of a crystallizer which comprises an inner sleeve provided with a lubricating oil channel, a water tank partition plate, an exhaust hole, an upper coil positioning clamping piece, a lower coil positioning clamping piece, a load coil, a water sealing plate and a water outlet. According to the semicontinuous casting liquid cave melt electromagnetic treatment device and the working method thereof, by adjusting the load coil parameters such as the frequency, the duty ratio and the average current intensity, electric current with different waveform characteristics can be obtained from the load coil, and therefore corresponding induced electromagnetic fields are obtained, and forced convection of corresponding forms is formed in liquid cave melt. By adoption of the semicontinuous casting liquid cave melt electromagnetic treatment device and the working method thereof, the problem that a light alloy semicontinuous casting blank cannot completely meet the requirements of a plastic deformation process for the grain size and component uniformity of the casting blank is solved.

Description

technical field [0001] The invention belongs to the field of metal material preparation, in particular to a semi-continuous casting method for realizing low-frequency electromagnetic oscillation or low-frequency electromagnetic forced pulsating flow of a semi-continuous casting liquid cavity melt. Background technique [0002] At present, except for a few highly active magnesium alloys (such as magnesium-lithium alloys) and magnesium alloys with high casting crack tendency (such as high rare earth alloyed magnesium alloys), magnesium alloys and aluminum alloys for deformation (including rolling, extrusion and forging) Billets are mostly prepared and produced by direct water-cooled semi-continuous casting process (ie DC casting). Although the DC casting process has obvious quality and efficiency advantages over permanent mold casting, due to its heat dissipation direction and cooling and solidification characteristics, metal billet casting including magnesium alloys and alumi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B22D11/115B22D11/16

CPCB22D11/115B22D11/16

Inventor 乐启炽侯健贾永辉陈星瑞宝磊张志强

Owner NORTHEASTERN UNIV LIAONING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com