Self-control system for preventing ice blockage of pressure regulating valve in distribution station

A technology of automatic control system and pressure regulating valve, which is used in pipeline system, gas/liquid distribution and storage, mechanical equipment, etc., can solve the problems of no automatic start function, waste of injected methanol, and large workload of personnel operation, so as to save equipment. The effect of operating time, reducing energy waste, and ensuring life safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

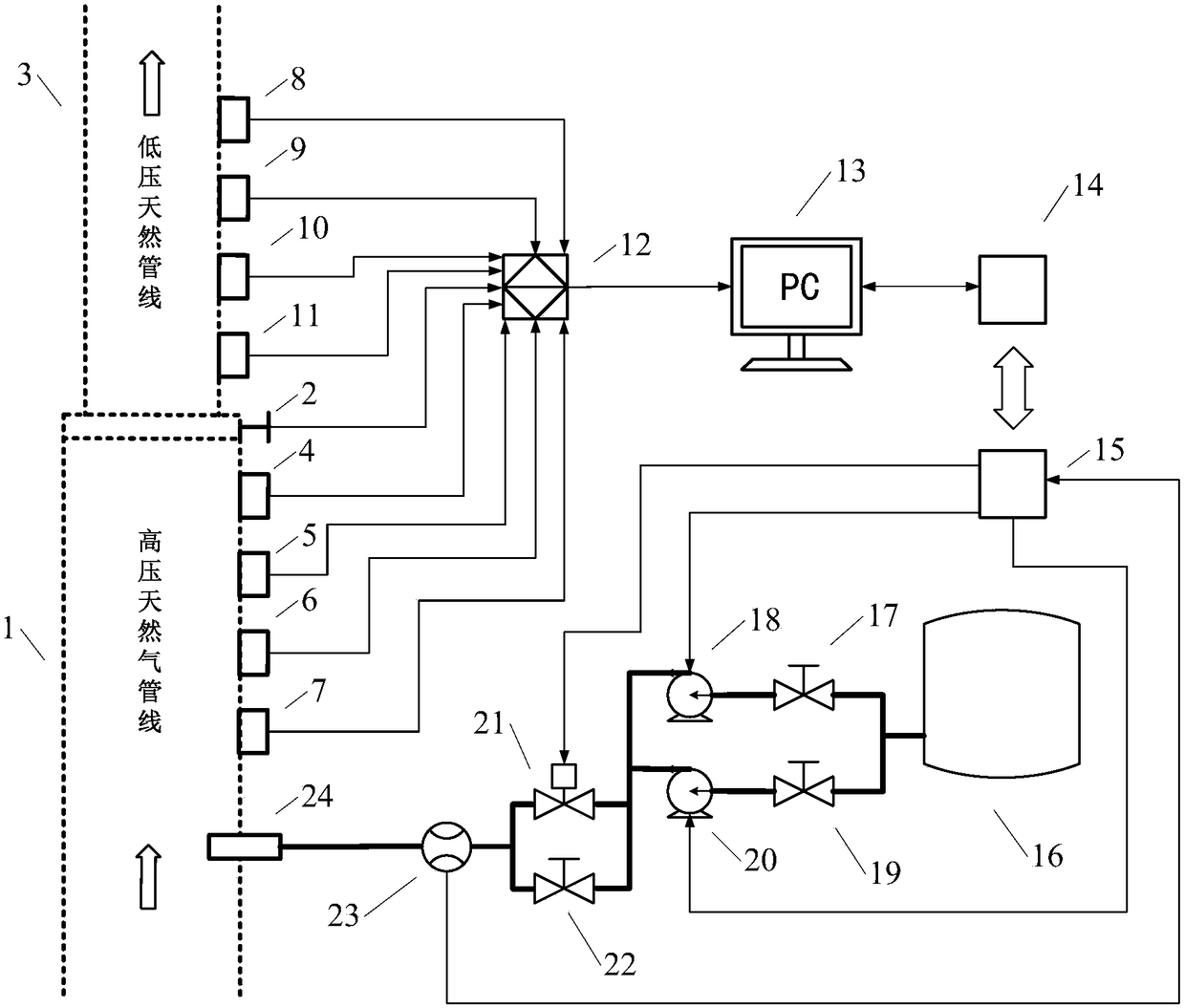

[0011] Such as figure 1 As shown, in the natural gas pipeline of the distribution station, the high-pressure natural gas pipeline 1 and the low-pressure natural gas pipeline 3 are connected through the distribution pressure regulating valve 2, and the high-pressure natural gas in the high-pressure natural gas pipeline 1 flows through the distribution pressure regulating valve 2 and then enters the low-pressure natural gas pipeline. Due to natural gas throttling effect due to the reduction of natural gas pressure, ice blockage is prone to occur at 2 places of the distribution pressure regulating valve.

[0012] Such as figure 1 As shown, the self-control system for preventing ice blockage of pressure regulating valves in distribution stations includes: on-site parameter acquisition module, on-site alcohol injection module, process control module and management module; on-site parameter acquisition module collects dew point, pressure, Flow, temperature parameters and valve open...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com