Raw material warehouse wall adhesive material removal method

A technology for raw material silo and silo wall, which is applied in the field of clearing blockage of sticky material on the silo wall of raw material silo, can solve the problems of unsmooth silo wall, environmental pollution, labor consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

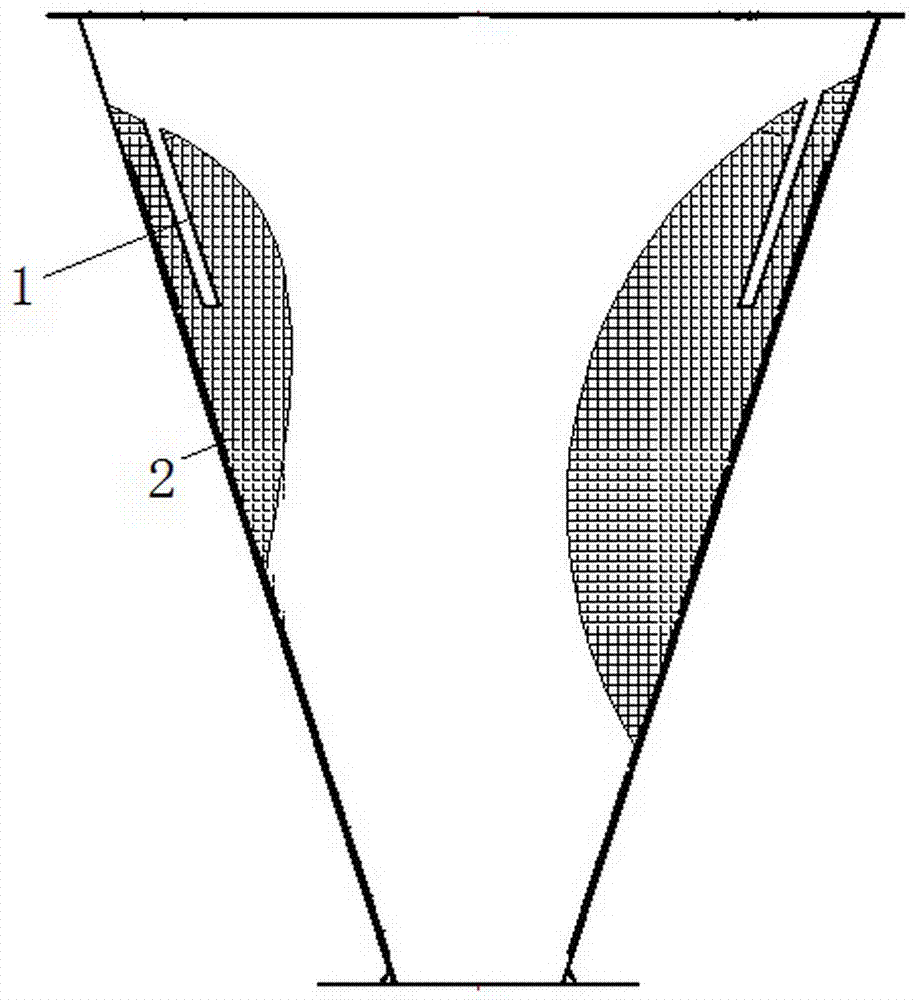

[0009] A method for clearing the sticky material on the wall of a raw material warehouse, such as figure 1 As shown, a immersion hole 1 with a diameter of 50 mm and a depth of 50 cm is drilled every 60 cm along the circumferential direction on the material adhered to the inner wall of the raw material silo. The axis of the immersion hole 1 is parallel to the wall 2 of the raw material silo. Inject water into the water pipe, change the hole after filling, and inject water in sequence. The water injection operation is repeated 3 times, stop for 2 hours, repeat the above water injection operation after 2 hours, and repeat the above water injection operation for 3 times, and then cooperate with the electric vibration of the warehouse wall until the sticky material falls off. fall.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com