Driver controller for EMU traction system

A driver controller and traction system technology, which is applied to railway braking systems, operating mechanisms of railway vehicle brakes, locomotives, etc. The effect of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

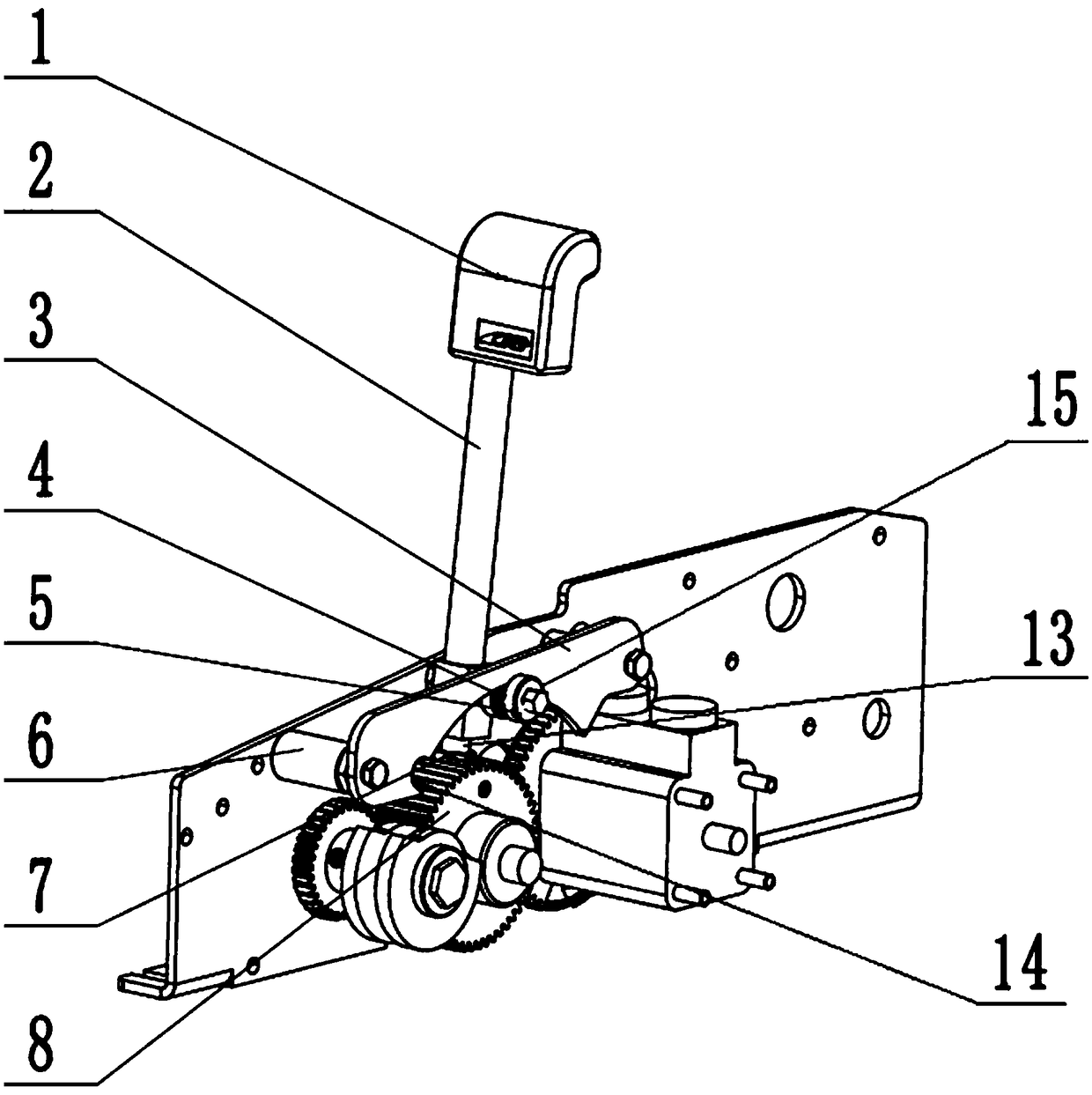

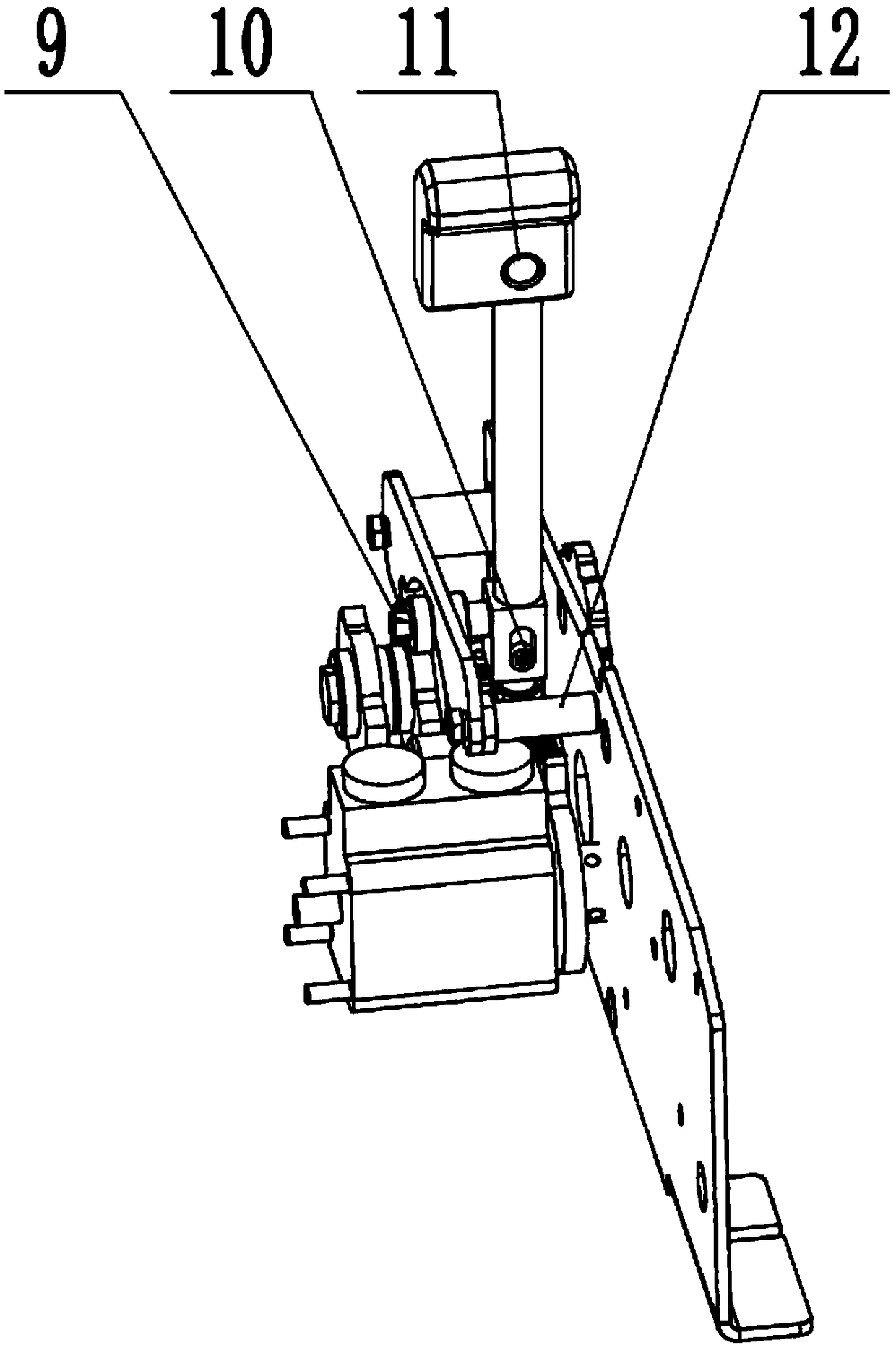

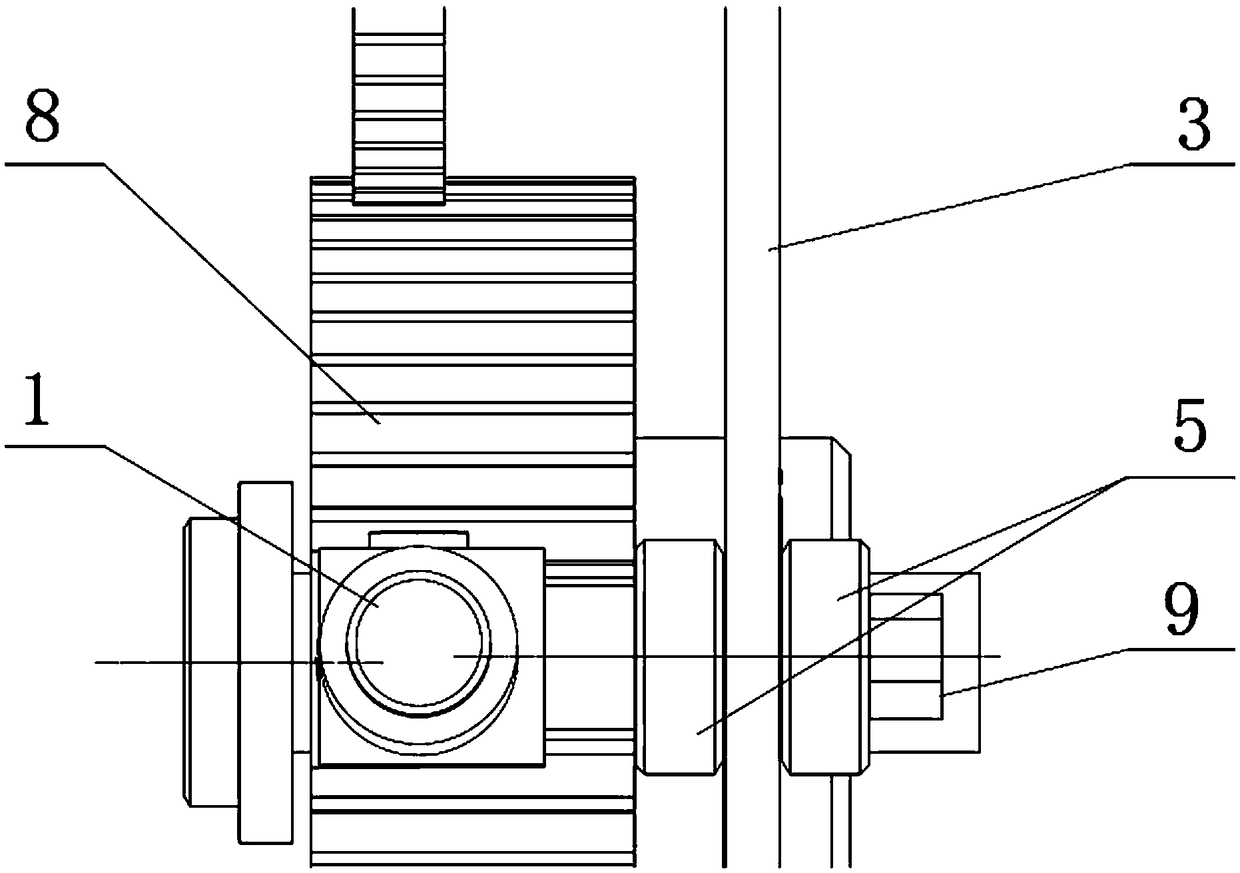

[0018] The structure of the driver controller for the traction system of an EMU provided by the present invention is as follows: Figure 1-Figure 3 As shown, it includes the driving gear 8 and the limiting plate 3 located on the same side of the left side plate, the limiting rod 13 is fixed on the driving gear 8, and the handle is also included. The lower end of the handle is fixed with a connector and is provided with an internal hollow cavity , the upper part of the limiting rod 13 is sleeved in the cavity and the two are connected by a spring, the connecting head is provided with a limiting groove along the length of the handle, and the upper part of the limiting rod 13 is located in the region of the limiting groove to fix the limiting screw 10 , the connecting head is fixed with a roller shaft 9 along the direction perpendicular to the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com