Distribution transformer prefabricated connection line with closed insulating cover

A technology of connecting wire and insulating cover, applied in the direction of connection, connection insulation, conductive connection, etc., can solve the problems of poor insulation performance of ordinary connecting wires, troublesome installation and construction, and great potential safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

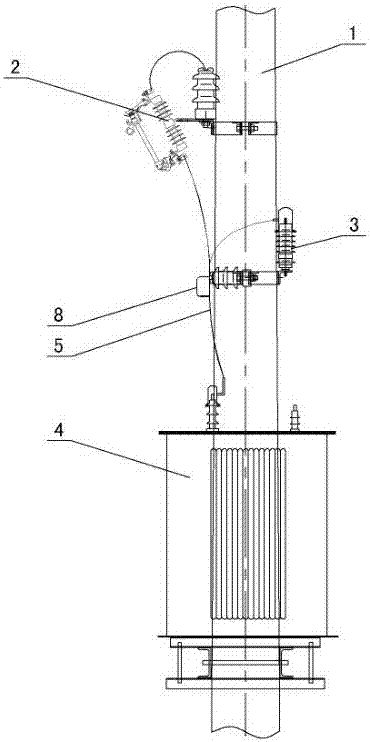

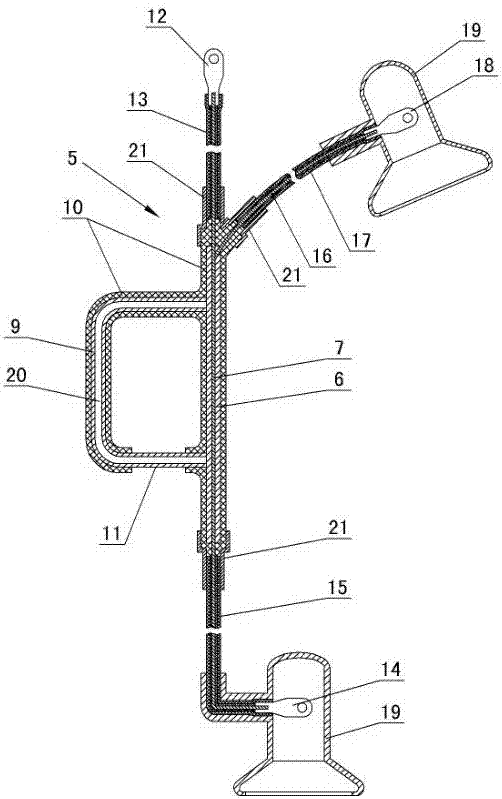

[0009] The invention relates to a prefabricated connection line for a distribution transformer with a closed insulating cover, such as figure 1 — figure 2 As shown, it includes a utility pole 1, on which a drop switch 2, a lightning arrester 3 and a transformer 4 are arranged, and the drop switch, the lightning arrester and the transformer are connected through a connection line 5, and it is characterized in that: the connection line 5 includes a main line copper pipe 6. The first plastic copper wire 7 is penetrated into the main line copper tube, and the electric test ground ring 8 is connected to the side wall of the main line copper tube 6. The electric test ground ring includes the ground ring copper tube 9, and the ground ring copper tube and the main line The copper tube is welded and connected, and the outer wall of the grounding ring copper tube and the main line copper tube is covered with a main line silicon rubber insulating layer 10. The main line silicon rubber i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com