A cylinder support tooling

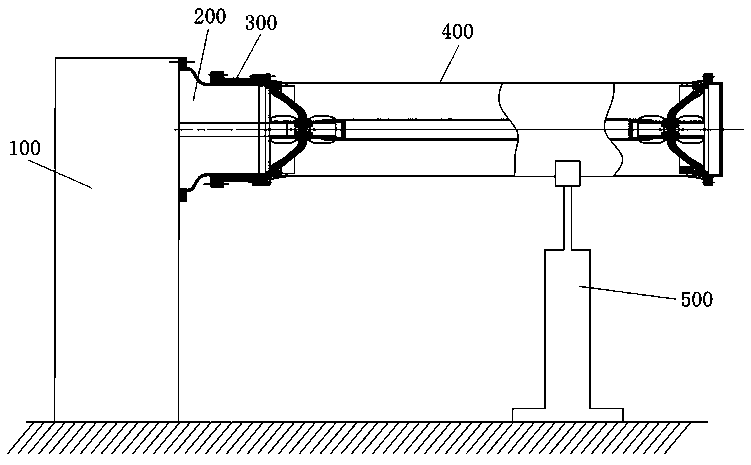

A tooling and barrel technology, applied in the direction of the casing of the measuring device, etc., can solve the problems of damage to the external structure of the busbar, low center height of the busbar, and unstable support.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

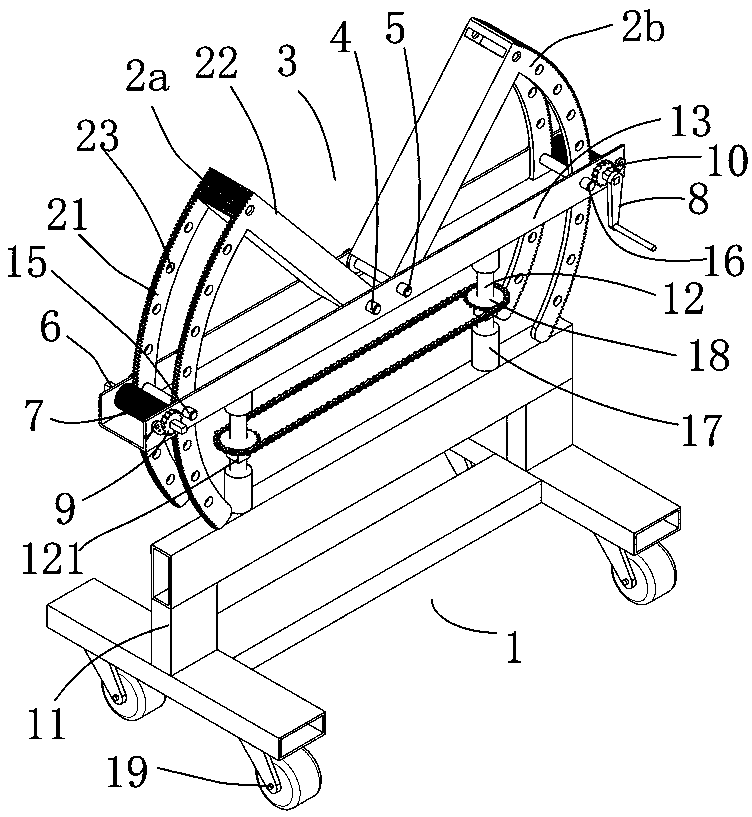

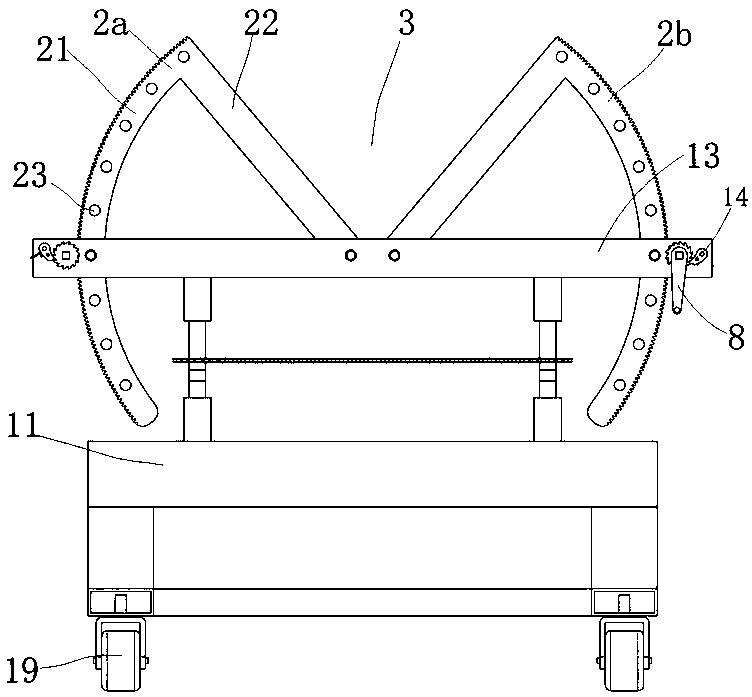

[0028] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0029] A specific embodiment 1 of a cylinder support tooling of the present invention, as Figure 2 to Figure 11 As shown, the cylinder support tool includes a bracket 1 and a first support arm 2a and a second support arm 2b arranged opposite to each other on the left and right. The bracket 1 includes a base 11 welded by square steel and steel plate, and a crossbeam 13 whose axis is set on the base 11 by a jacking mechanism and extends along the left and right directions. The crossbeam 13 is made of channel steel material. In this embodiment, the structures of the first support arm 2a and the second support arm 2b are exactly the same, and each of the first support arm and the second support arm includes an arc-shaped plate portion 21 and a support rod extending radially along the arc-shaped plate portion The part 22, the arc-shaped plate part and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com