Bearing clearance detector

A technology of bearing clearance and detector, applied in the direction of mechanical clearance measurement, etc., can solve problems such as unreasonable structural design, affecting detection efficiency, complex bearing tooling structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

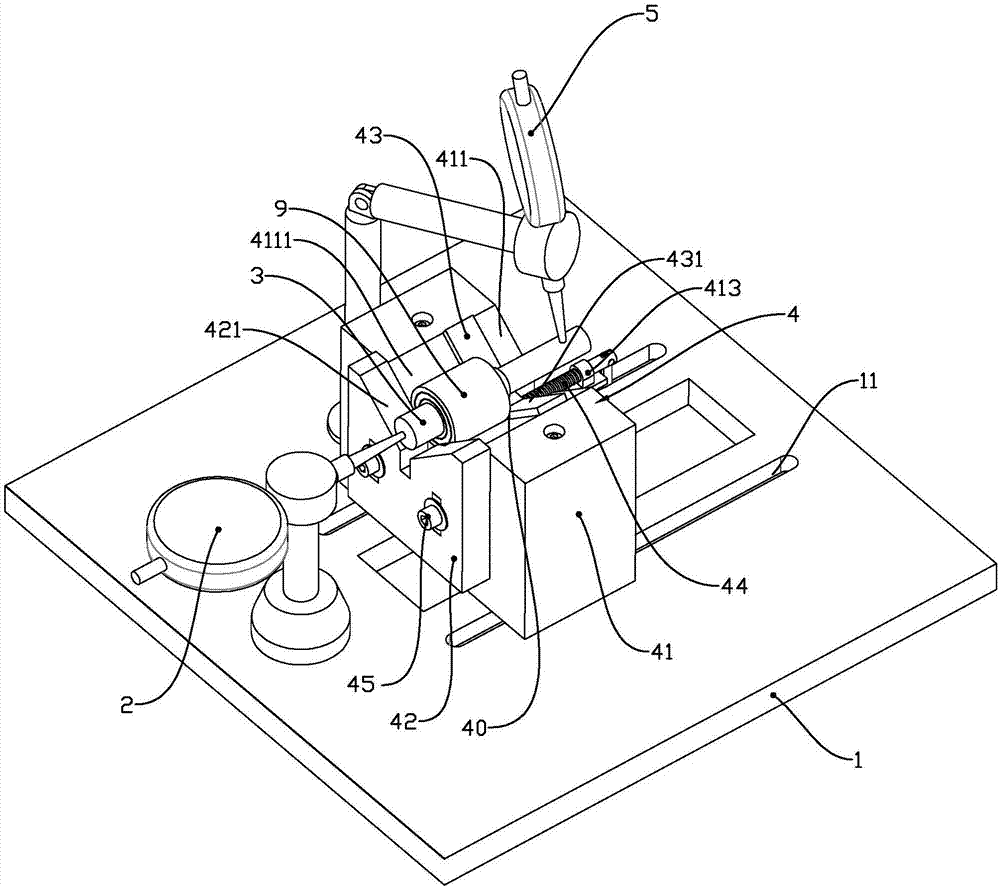

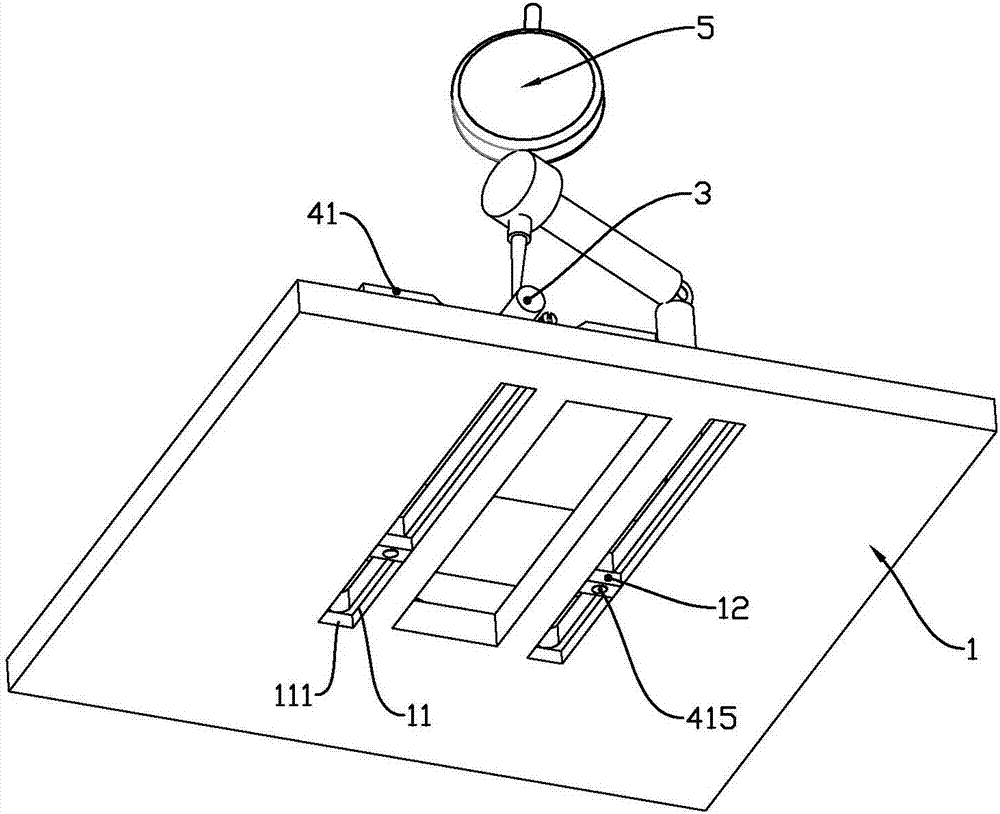

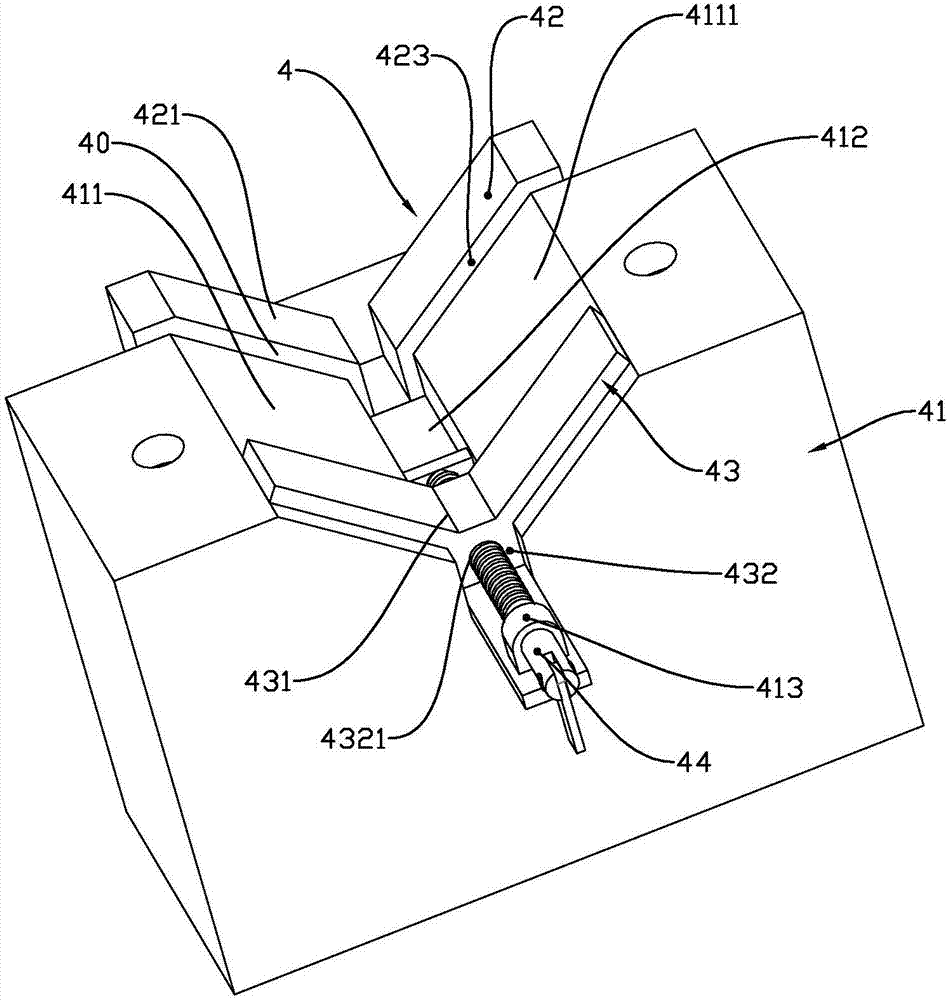

[0019] See attached figure 1 To attach Figure 4 , a bearing clearance detector disclosed in the present invention comprises a substrate 1, an axial clearance detection gauge 2, a mandrel 3 inserted on the inner ring of a bearing 9 to be tested, and a bearing fixing tool 4, and the axial clearance detection The table head of Table 2 is in conflict with the axial end of the mandrel 3. The bearing fixing tool 4 includes a support seat 41 fixed on the base plate 1. The support seat 41 is provided with a clamping mechanism for fastening the outer ring of the bearing to be tested. The top of the support seat 41 is provided with a V-shaped groove 411, and the clamping mechanism includes a first clamping block 42 and a second clamping block 43 arranged at intervals along the length direction of the V-shaped groove 411. The first clamping block 42 and the second clamping block 43 are spaced apart to form a clamping cavity 40 for axially clamping the outer ring of the bearing 9 to be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com