Hydrostatic Axial Piston Machine with Inclined Shaft Structure

An axial piston engine, hydrostatic technology, applied in reciprocating piston engine, variable displacement engine, liquid variable displacement machinery, etc., can solve the problems of axial piston engine failure, piston breakage, etc. Strength-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

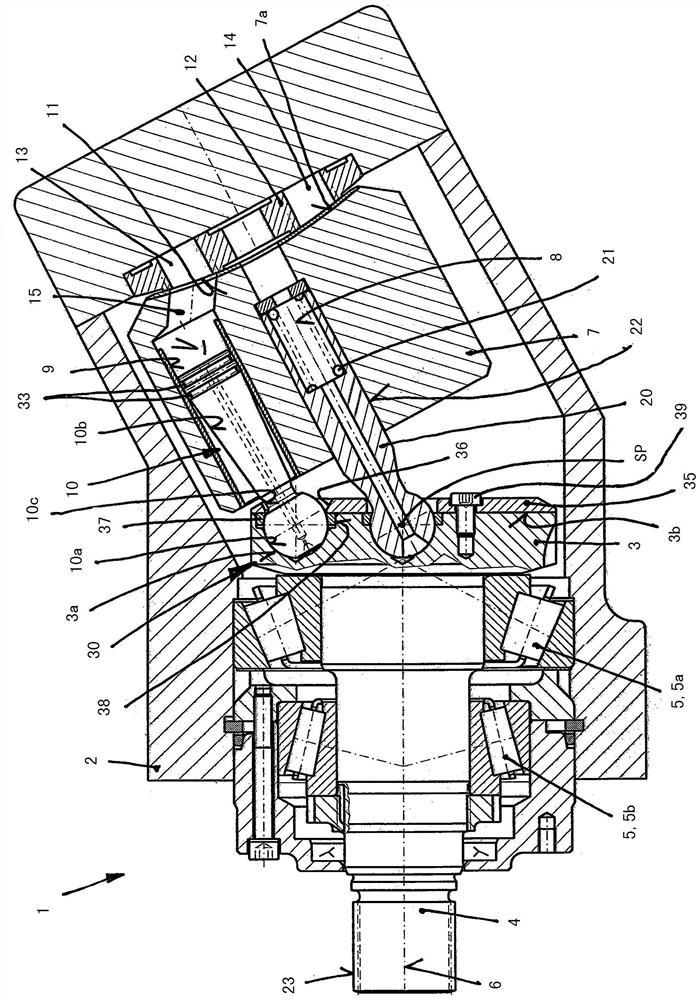

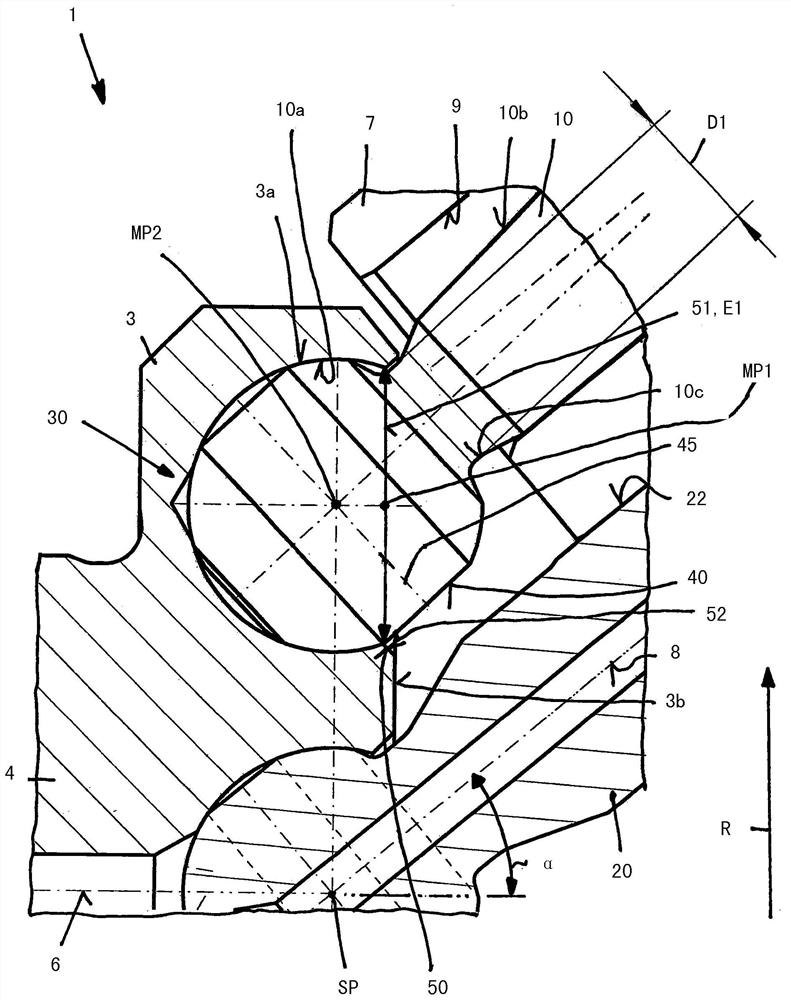

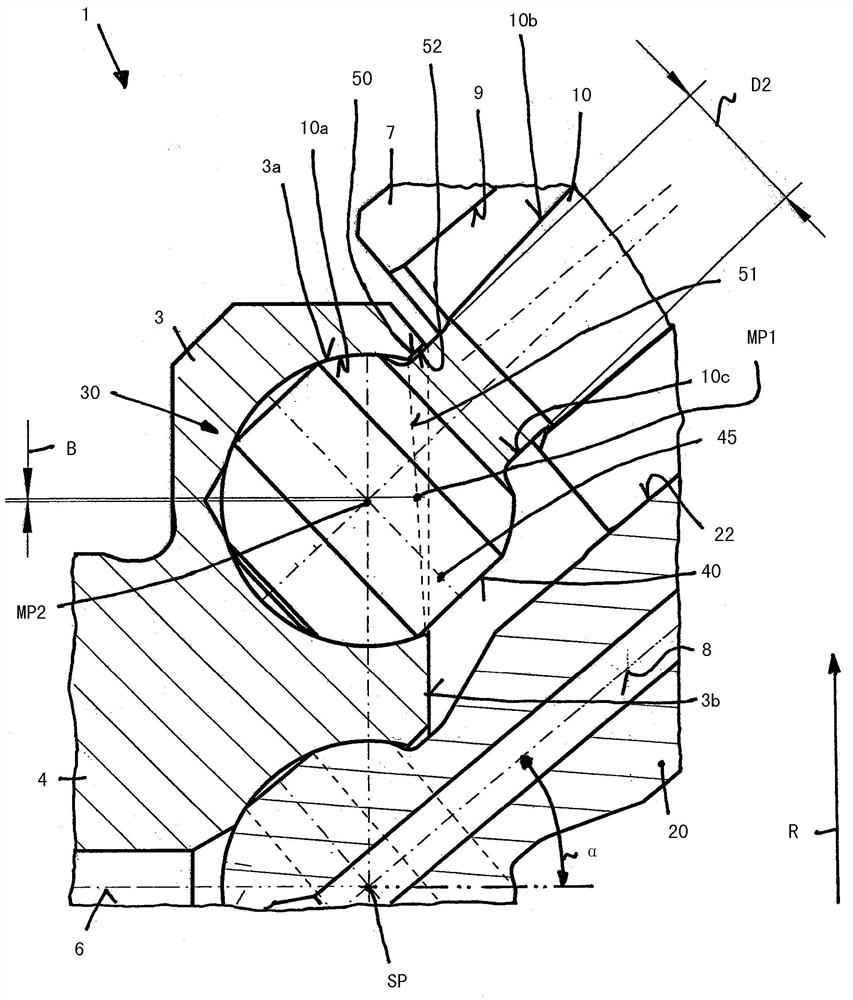

[0024] exist figure 1 The hydrostatic axial piston machine of the oblique shaft structure mode of the prior art occurs with a longitudinal section illustration in the figure. An axial piston machine 1 designed as an inclined-axis machine has a housing 2 in which a drive shaft 4 provided with a drive flange 3 is mounted rotatably about an axis of rotation 6 by means of a bearing device 5 .

[0025] A cylinder 7 arranged axially adjacent to the drive flange 3 in the housing 2 is arranged rotatably about an axis of rotation 8 , provided with a plurality of pistons arranged concentrically with the axis of rotation 8 of the cylinder 7 Recesses 9 in which a piston 10 is arranged longitudinally displaceable in each case.

[0026] The axis of rotation 6 of the drive shaft 4 intersects the axis of rotation 8 of the cylinder 7 at a point of intersection SP.

[0027] The cylinder barrel 7 bears against the control body 12 provided with the control surface 11 via the end face 7a. A sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com