Seamless adhesion preparation method of double-layer cloth

A seamless, double-layer technology, applied in the field of seamless bonding of double-layer cloth, can solve the problems of long production time, high rejection rate and low efficiency, and achieve the effect of reducing equipment investment, high precision and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0035] In this embodiment, the shapes of fabrics A and B are circular as an implementation, and other shapes of contours can be set according to different purposes.

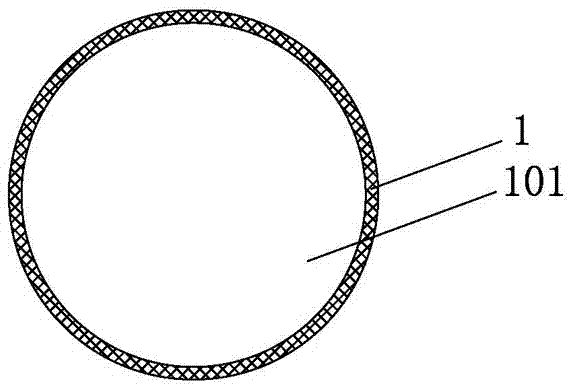

[0036] Such as Figure 1 to Figure 9 As shown, a preparation method for seamless bonding of double-layer fabrics includes fabric A and fabric B having the same shape, fabric A and fabric B are bonded by a hot-melt adhesive frame 1 close to the edge to form a double-layer fabric, and its characteristics Yes, including the following steps:

[0037] (1) Prepare fabric A, fabric B and hot-melt adhesive film 2 in roll form, and the hot-melt adhesive film includes adhesive film 201 and release paper 202;

[0038] (2) Prepare high-temperature-resistant single-sided adhesive tape 3 in coil form;

[0039] (3) Import the hot-melt adhesive film into the die-cutting machine, punch out the hollow in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com