Rolling and machining composite processing device and method for rotating deep-cavity curved surface member

A composite processing and rolling machine technology, applied in the direction of manufacturing tools, other manufacturing equipment/tools, etc., can solve the problems of high processing cost and parts damage, and achieve the effect of reducing transportation, reducing the number of tooling, and removing the amount of clamping tasks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Hereinafter, the present invention will be further described in conjunction with the drawings and embodiments.

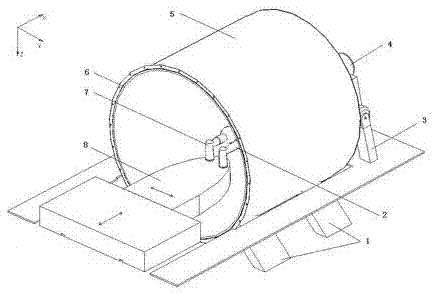

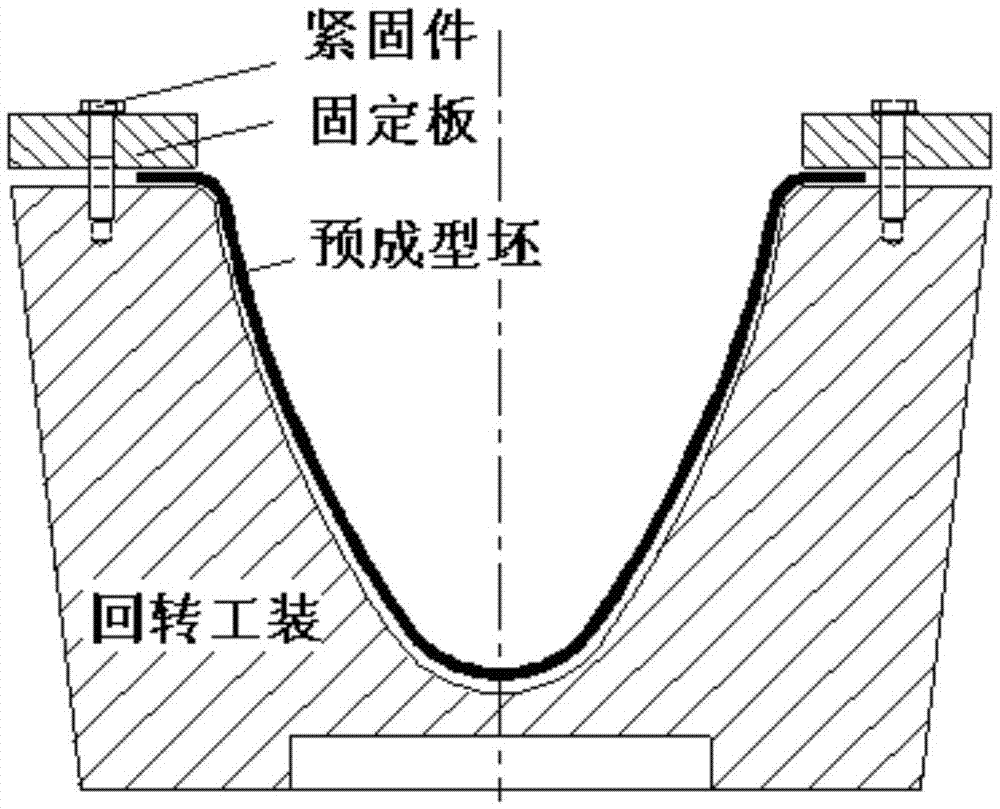

[0028] refer to figure 1 , the rotary deep cavity curved surface member rolling machine and composite processing device provided by the present invention includes: rotary tooling 5, the mandrel is installed in the outer drum to form the rotary tooling 5, and the preform is fixed in the rotary tooling 5 during processing ; the feed platform 8, the feed platform 8 has a degree of freedom in the horizontal direction relative to the rotary tooling 5; the rolling module 7 and the machining module 2 fixed on the feed platform 8, the rolling module 7 and The machining module 2 has a degree of freedom of rotation around a vertical axis.

[0029] The inner mandrel of the rotary tooling 5 is determined according to the size of the parts in the rotary deep cavity, and the diameter can be variable in the range of 2000mm-5500mm; the contour of the outer drum is a conical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com