Seed sowing device combining scoop-type seed extraction and piston hole pricking

A piston and spoon-type technology, applied in sowing, planter parts, hole-seeding planters, etc., can solve the problems of difficulty in guaranteeing hole-seeding quality, easily obstructed soil by hole-forming mechanism, and restricting popularization and application, and achieves novel structure and quality of hole-forming. Good, good synchronization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

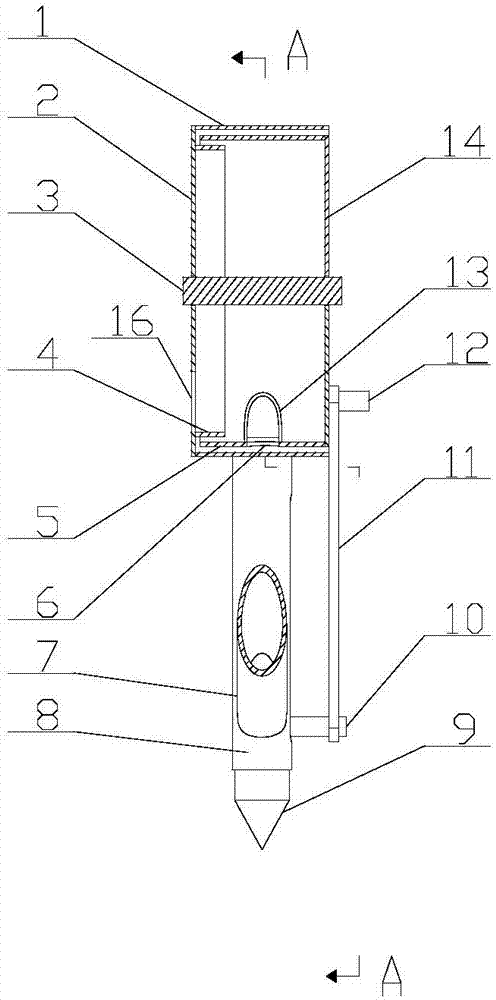

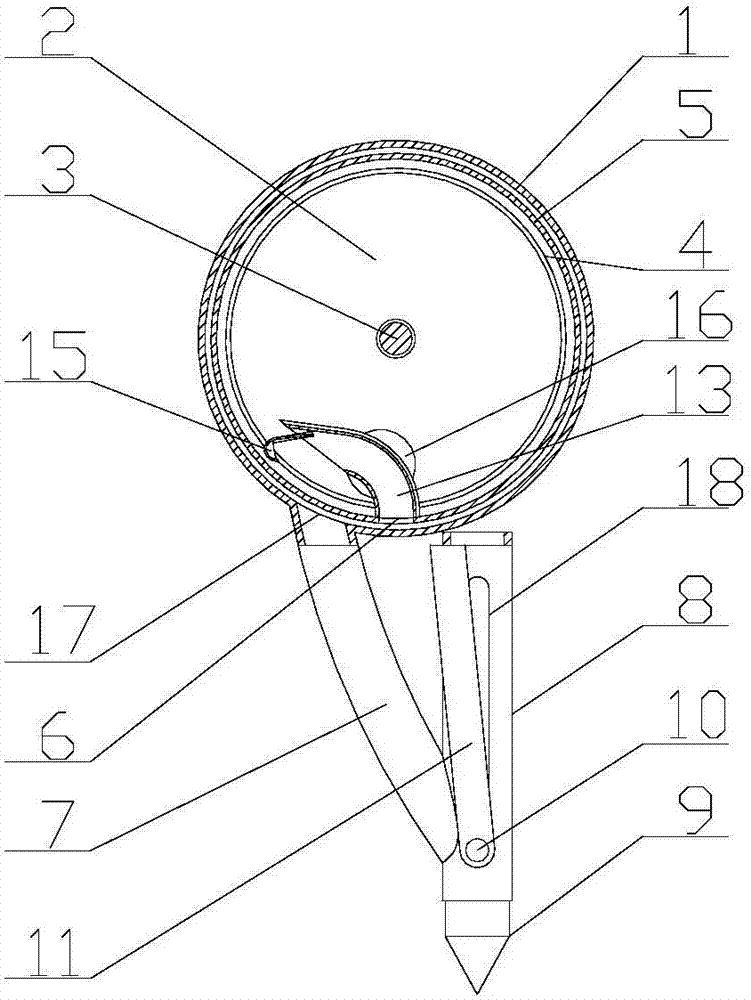

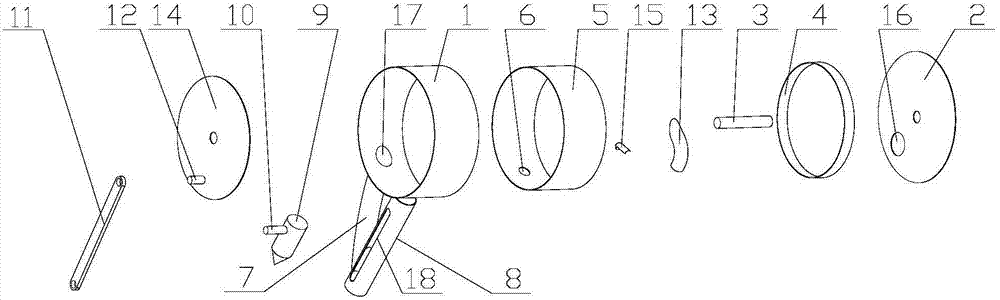

[0011] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. A kind of seed metering device combined with spoon-type seed taking and piston hole pricking. The left cover plate 2 is sealed and fixed on the left end of the cylindrical outer cylinder 1, and the seed inlet 16 is opened on the left cover plate 2. A seed discharge opening 17 is provided on the bottom side of the cylinder wall of the cylindrical outer cylinder 1, and the inner ring 4 of the slideway is fixed on the inner wall surface of the left cover plate 2, and the cylindrical inner cylinder 5 is rotatably inserted and arranged on the cylindrical surface. In the annular slideway formed between the inner wall surface of the outer cylinder body 1 and the outer wall surface of the inner ring 4 of the slideway, the right cover plate 14 is sealed and fixed on the right end of the cylindrical inner cylinder body 5, and is set on the wall of the cylindrical i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com